Method for synthesizing alkyl glycoside 0810 from dextrose monohydrate

A technology of alkyl glucoside and glucose, which is applied in the field of synthesizing alkyl glycoside 0810 from glucose monohydrate, which can solve the problems of slow solid-liquid reaction rate, difficult reaction of glucose, and aggregation and agglomeration of glucose, and achieves accelerated dissolution, convenient operation, and easy dilution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

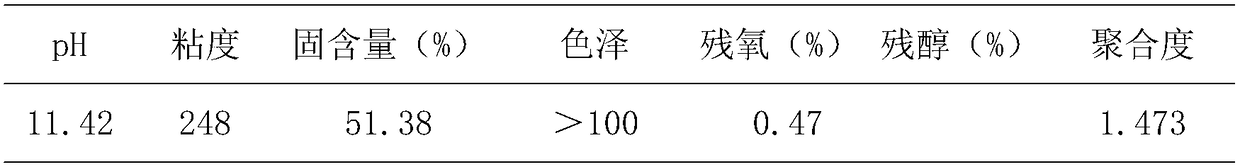

Examples

Embodiment 1

[0019] Embodiment 1: 8:10 Feeding: Glucose monohydrate 198g; n-octanol, n-decyl alcohol mixed alcohol (1:1) 420g;

[0020] 8:15 Feeding ends, negative pressure heats up;

[0021] 8:35 Alcohol and sugar mixed with reflux and dehydrated for one hour;

[0022] 9:35 Stop heating, add activated carbon and PTSA, pass CO 2 , the feed rate is 1.5ml / min, the temperature is raised to 103°C, and the reaction timing starts;

[0023] 11:35 104°C;

[0024] 13:25 105°C, stop heating;

[0025] 13:35 Add 0.08g MgO, 1.6g 32% liquid caustic soda, the reaction solution turns yellow and turbid;

[0026] the next day:

[0027] 7:50 direct vacuum distillation without filtration, low pressure degassing;

[0028] 8:25 began to distill alcohol;

[0029] 9:50 After the distillation at 170°C, 326.3g of mixed alcohols and 255.4g of crude glycosides were distilled out;

[0030] 10:00 Add 209g of purified water, add 32% liquid caustic soda, 20.9g;

[0031] 10:10 Add 13g of 30% hydrogen peroxide;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com