Molybdenum phenolic resin for water-soluble rock wool, adhesive, preparation method and application thereof

A molybdenum phenolic resin, water-soluble technology, applied in the field of water-soluble molybdenum phenolic resin for rock wool and its adhesive and preparation field, can solve the problems of poor storage stability, high free phenol/aldehyde content, limited thermal stability of PF, etc. , to achieve the effect of strong storage stability, low free phenol and free aldehyde content, and improved thermal stability of rock wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

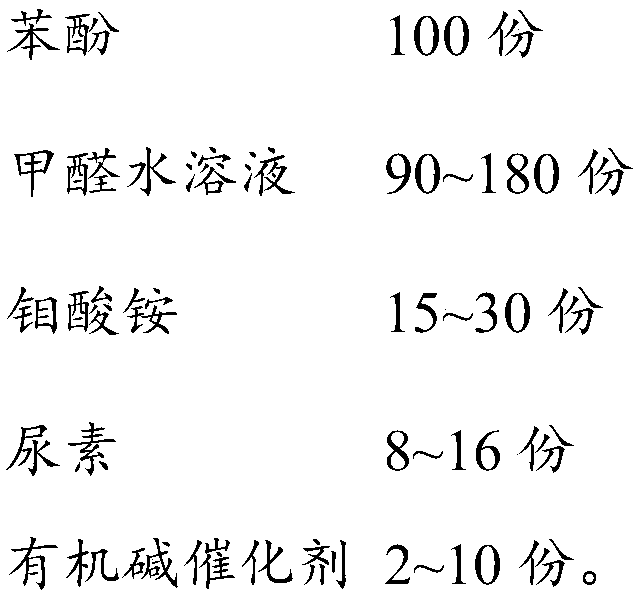

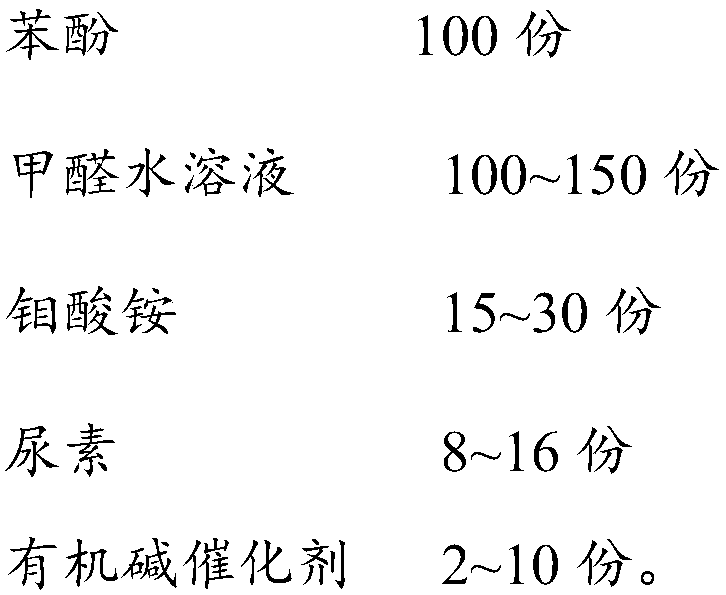

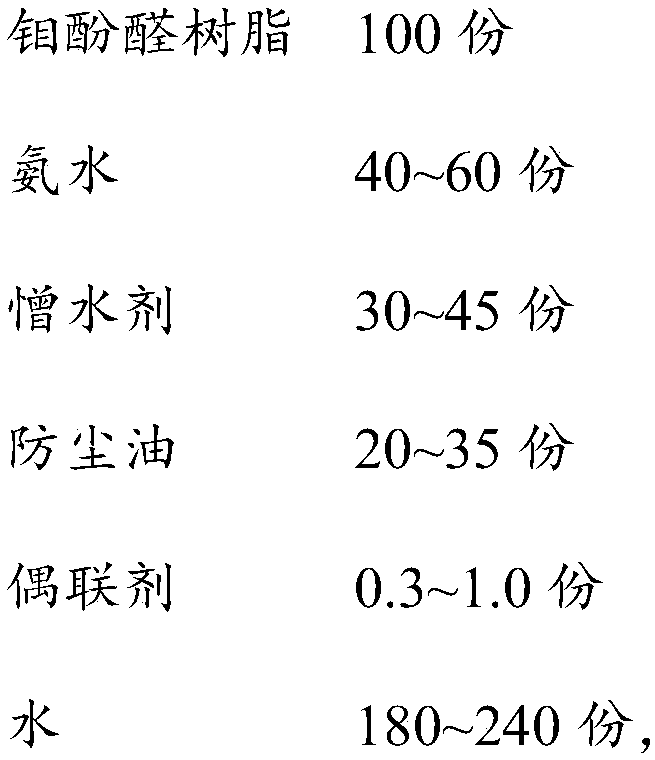

Method used

Image

Examples

Embodiment 1

[0044] Molybdenum is prepared by

[0045] Phenolic resin product 1

[0046] 1) Melting 100 parts by weight of phenol under airtight conditions at 40°C for subsequent use;

[0047] 2) Adjust the reaction temperature to 60-70°C, add 15 parts by weight of ammonium molybdate to the phenol melt, add formaldehyde solution dropwise and keep stirring, finally add 100 parts by weight of formaldehyde solution, and finally make the moles of phenol and formaldehyde The ratio is 1:1.2~2.0, and the reaction time is 1.0~2.0h to obtain the reaction solution;

[0048] 3) Add 2 parts by weight of ammonia water / triethylamine system to the reaction liquid in step 2), and add 5 parts by weight of urea at the same time, control the temperature at 60-70°C, keep it warm for 1.0-1.5h, and measure the free aldehyde content. Add the remaining urea to the content of the remaining urea, and add about 11 parts by weight of urea until the free aldehyde content reaches the standard, and cool;

[0049] 4) ...

Embodiment 2

[0051] Molybdenum phenolic resin product was prepared by the following method 2

[0052] 1) Melting 100 parts by weight of phenol under airtight conditions at 40°C for subsequent use;

[0053] 2) Adjust the reaction temperature to 60-70°C, add 30 parts by weight of ammonium molybdate to the phenol melt, add formaldehyde solution dropwise and keep stirring, finally add 150 parts by weight of formaldehyde solution, and finally make the moles of phenol and formaldehyde The ratio is 1:1.2~2.0, and the reaction time is 1.0~2.0h to obtain the reaction solution;

[0054] 3) Add 10 parts by weight of ammonia water / ethylenediamine system to the reaction solution in step 2), and add 2.5 parts by weight of urea at the same time, control the temperature at 60-70°C, keep it warm for 1.0-1.5 hours, and measure the free aldehyde content. Add the remaining urea to the content of the remaining urea, add about 5.5 parts by weight of urea until the free aldehyde content reaches the standard, an...

Embodiment 3

[0057] Molybdenum phenolic resin product was prepared by the following method 3

[0058] 1) Melting 100 parts by weight of phenol under airtight conditions at 40°C for subsequent use;

[0059] 2) Adjust the reaction temperature to 60-70°C, add 25 parts by weight of ammonium molybdate to the phenol melt, add formaldehyde solution dropwise and keep stirring, finally add 120 parts by weight of formaldehyde solution, and the reaction time is 1.0-2.0h Obtain the reaction solution;

[0060] 3) Add 20 parts by weight of ammonia water / triethylamine system to the reaction solution in step 2), and add 4 parts by weight of urea at the same time, control the temperature at 60-70°C, keep it warm for 1.0-1.5h, and measure the free aldehyde content. Add the remaining urea to the content of the remaining urea, and then add 8 parts by weight of urea until the free aldehyde content reaches the standard, and cool;

[0061] 4) Use ammonia water to adjust the pH of the solution to 7.0-8.0, conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com