Water-based paint with high thermal conductive and insulating properties

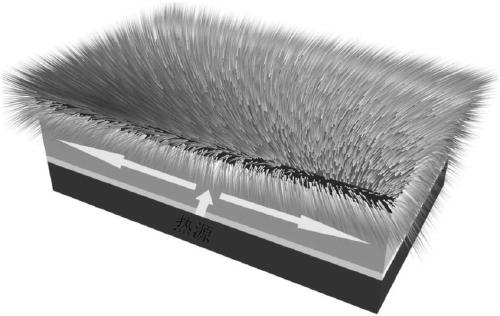

A water-based coating, high thermal conductivity technology, used in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of neglecting the influence of thermal conductivity, not exceeding 1.3W, blindness in coating design and preparation, etc. , to achieve considerable market prospects, ease of processing, and the effect of increasing the effective heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

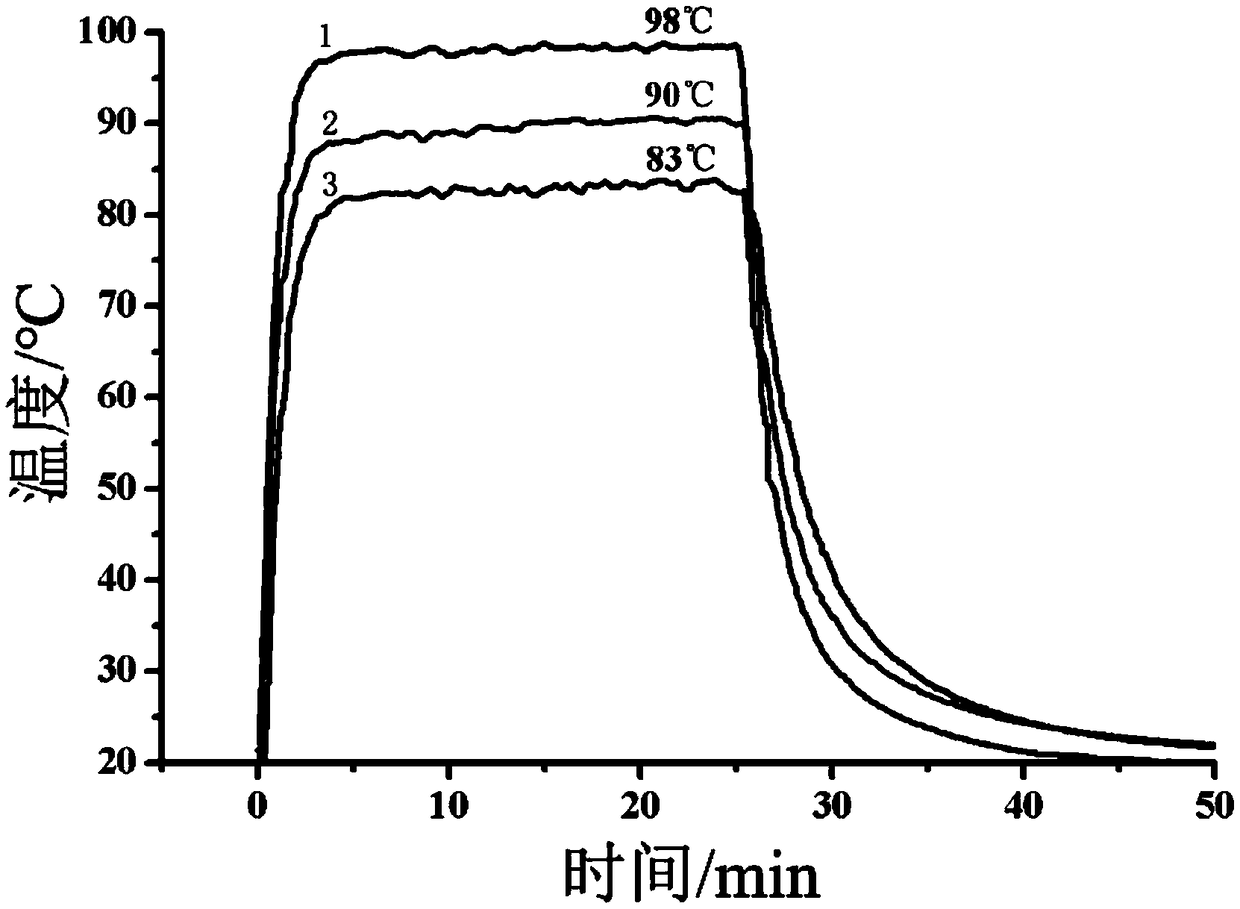

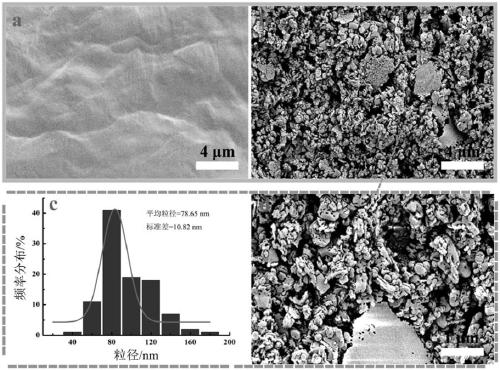

[0039] The high thermal conductivity insulating water-based paint prepared in this example includes raw materials including high thermal conductivity insulating fillers, water-based emulsions and additives. The high thermal conductivity insulating filler includes 3% aluminum nitride (size 100nm), 0.5% aluminum oxide (size 2μm), 1.5% silicon carbide (particle size 50nm) by weight percentage; the auxiliary agent includes 4% film-forming aid, 0.5% leveling agent, 1% antioxidant, 1.5% dispersant, 0.5% defoamer, 2% thickener, 1% matting agent, 0.5% corrosion inhibitor, 0.5% colorant and 0.5% pH regulator; The water-based polymer emulsion is 83% water-based polyurethane by weight percentage.

[0040] After blending the above-mentioned raw materials, a high thermal conductivity and insulating water-based coating is coated on the substrate, and samples are prepared according to the requirements of various tests. The performance data are listed in Table 1 below.

[0041] Performance T...

Embodiment 2

[0054] The high thermal conductivity insulating water-based paint prepared in this example includes raw materials including high thermal conductivity insulating fillers, water-based emulsions and additives. High thermal conductivity insulating filler includes 0.5% boron nitride (size 5μm), 1.5% aluminum nitride (size 50nm), 3% aluminum oxide (particle size 100nm) by weight percentage; auxiliary agent includes 4% film-forming aid by weight percentage , 1% leveling agent, 1% antioxidant, 1.5% dispersant, 0.5% defoamer, 2% thickener, 1% matting agent, 0.5% anti-skinning agent and 0.5% pH regulator; water-based polymer The emulsion was 83% waterborne epoxy resin by weight.

Embodiment 3

[0060] The high thermal conductivity insulating water-based coating prepared in this embodiment includes high thermal conductivity insulating fillers, water-based emulsion and additives. The high thermal conductivity insulating filler includes 0.5% aluminum oxide (size 1μm), 1.5% boron nitride (size 50nm), 2% silicon carbide (size 100nm) by weight percentage; additives include 4% film-forming aid, 1.5% by weight % leveling agent, 1% antioxidant, 1.5% dispersant, 0.5% defoamer, 2% thickener, 2% matting agent and 0.5% corrosion inhibitor; water-based polymer emulsion is 83% water-based by weight Fluorine resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com