Inorganic ammonium perovskite quantum dot material and synthesis method

A technology of quantum dot material and synthesis method, which is applied in the synthesis field of pure ammonium perovskite quantum dot material, can solve the problems of poor stability, short storage time, unfavorable use and the like, and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

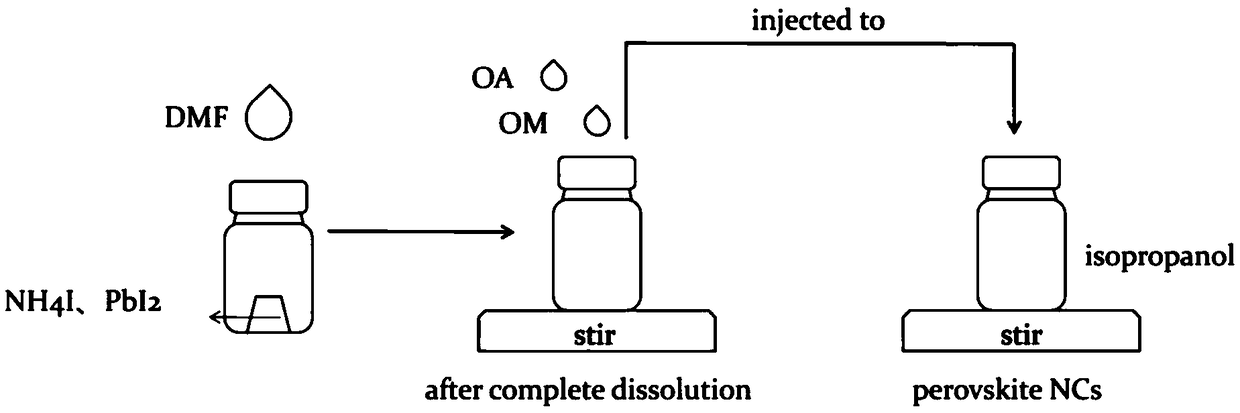

[0029] A kind of inorganic ammonium perovskite quantum dot, its specific preparation steps are as follows:

[0030] Step 1. Clean glass bottle A and glass bottle B; wash glass bottle A and glass bottle B with deionized water, acetone, isopropanol, and deionized water for 10 minutes each, and then blow dry with a nitrogen gun;

[0031] Step 2, the ammonium iodide (NH 4 I) and 0.1mmol lead iodide (PbI 2 ) into the glass bottle A, successively add 5mL dimethylformamide to the glass bottle A as a solvent for dissolving the reactant, then add 100uL of oleic acid and 50uL of oleylamine, the resulting solution is a precursor solution;

[0032] Step 3. Add 5mL of isopropanol to glass bottle B as anti-solvent;

[0033] Step 4. Rapidly inject 50uL of the precursor solution into the anti-solvent of the glass bottle B, and fully stir the reaction to obtain a suspension;

[0034] Step 5, take out the suspension in the glass bottle B, centrifuge at 6000rpm and take the supernatant to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com