A method for producing ethanol by reusing anaerobic digestion effluent and refining tower residue

An anaerobic digestion and raffinate technology, applied in the direction of fermentation, etc., can solve the problems of poisoning ethanol fermentation yeast, reduce the utilization rate of raw materials, increase operation and cost, etc., so as to avoid acid production in ethanol fermentation, improve the performance of ethanol fermentation, and improve the process Hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

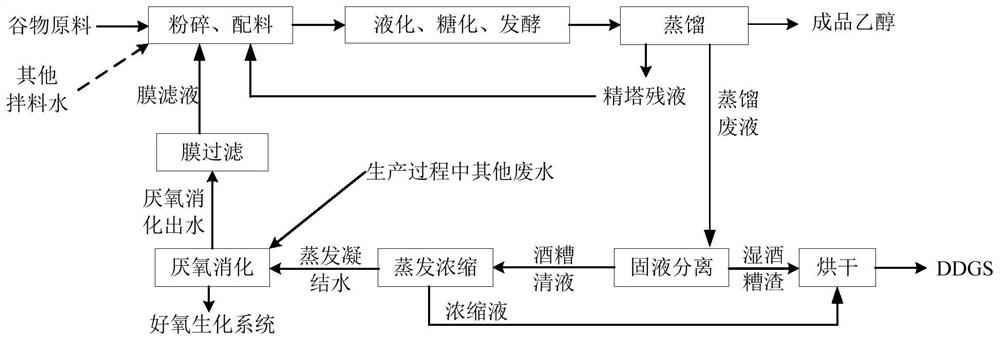

[0062] A method for producing ethanol by reusing anaerobic digestion effluent and refining tower residue of the present invention adopts the following process steps:

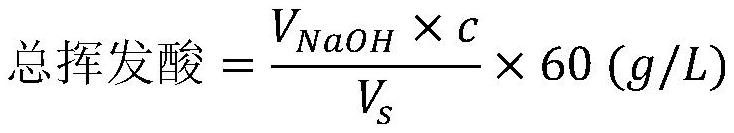

[0063] Membrane filtrate and fine tower residual liquid are mixed according to the ratio of 85:15, and volatile acid concentration is 600mg / L; Get the cornflour 100Kg after pulverizing, add 310L mixed solution batching, add high temperature resistant α-amylase (10U / g amylase ), stir evenly, heat to 86°C and maintain for 200min; cool down to 60°C, add glucoamylase (180U / g starch), stir evenly, and keep warm for saccharification for 15min. After the saccharification is completed, the temperature is lowered to 30°C, and 15% (v / v) yeast seed liquid is added to start fermentation. After fermentation, ethanol, distillation waste liquid and fine tower residue are obtained through distillation. The distillation waste liquid is filtered with a 60-mesh filter cloth to obtain wet distiller's grain residue and distiller's ...

Embodiment 2

[0066] A method for producing ethanol by reusing anaerobic digestion effluent and refining tower residue of the present invention adopts the following process steps:

[0067] Membrane filtrate and refining tower residual liquid are mixed according to the ratio of 90:10, and volatile acid concentration is 400mg / L; Get the brown rice flour 100Kg after pulverizing, add 260L mixed solution batching, add high temperature resistant α-amylase (8U / g amylase ), stirred evenly, heated to 90°C and maintained for 100min; cooled to 58°C, added glucoamylase (150U / g starch), stirred evenly, and kept warm for saccharification for 30min. After the saccharification is completed, the temperature is lowered to 30° C., and 10% (v / v) yeast seed liquid is inserted to start fermentation. After fermentation, ethanol, distillation waste liquid and fine tower residue are obtained through distillation. The distillation waste liquid is filtered with a 60-mesh filter cloth to obtain wet distiller's grain ...

Embodiment 3

[0070] A method for producing ethanol by reusing anaerobic digestion effluent and refining tower residue of the present invention adopts the following process steps:

[0071]The membrane filtrate and the refining tower residue are mixed according to the ratio of 99:1, and the concentration of volatile acid is 100mg / L; 1000Kg of pulverized brown rice flour is taken and added to 2600L of mixed solution as ingredients, and high-temperature-resistant α-amylase (15U / g starch) is added , stir evenly, heat to 95°C and maintain for 100min; cool down to 60°C, add glucoamylase (160U / g starch), stir well, and keep warm for saccharification for 30min. After the saccharification is completed, the temperature is lowered to 30° C., and 12% (v / v) yeast seed liquid is inserted to start fermentation. After fermentation, ethanol, distillation waste liquid and fine tower residue are obtained through distillation. The distillation waste liquid is filtered with a 60-mesh filter cloth to obtain wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com