A regeneration treatment method of lithium iron phosphate waste

A lithium iron phosphate and treatment method technology, which is applied in the field of regeneration treatment of lithium iron phosphate waste, can solve problems such as the performance of lithium iron phosphate materials needs to be improved, the difficulty of recycling lithium iron phosphate waste, and the strict requirements for waste components, so as to avoid alkali The generation of non-toxic substances and lithium phosphate, the saving of chemical raw materials, and the effect of low recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

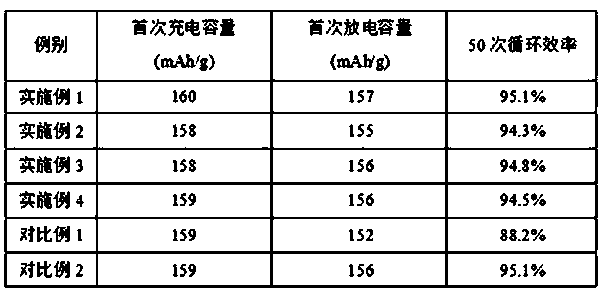

Examples

Embodiment 1

[0033] (1) Dissolution: The waste of lithium iron phosphate production with unqualified physical and chemical properties was taken for component analysis. The test results showed that the main components of the waste were: lithium 4.22wt%, iron 33.36wt%, phosphate radical 58.2wt%, carbon 2.46wt% and 1.733wt% % other unavoidable trace elements, determine the effective molar weight of the waste material, i.e. the molar weight of lithium iron phosphate, the waste material is proportioned by the effective amount and sulfuric acid with a molar weight of 1:1.5, and the waste material 645.30g, wt% is 98 Concentrated sulfuric acid 600g and deionized water 4000g were stirred and dissolved at room temperature under nitrogen protection for 2 hours to prepare a solution with a hydrogen ion concentration of 2.0mol / L;

[0034] (2) Separation: Use a vacuum filter to filter the solution prepared in step (1) to obtain 3992.7 g of the primary filtrate and 499.5 g of the primary filter residue, w...

Embodiment 2

[0042] (1) Dissolution: Take the lithium-deficient (unqualified ratio) lithium iron phosphate production material for component analysis. The test results show that the main components of the waste are: lithium 3.91wt%, iron 33.46wt%, phosphate radical 58.5wt%, carbon 2.24wt% %. And 2.09wt% other unavoidable trace elements, determine the effective molar weight of the waste material, i.e. the molar weight of lithium iron phosphate, mix the waste material according to the effective amount and hydrochloric acid with a molar weight of 1:4, weigh the waste material 643.10g, wt% 1600g of 36.5 concentrated hydrochloric acid and 984g of deionized water were stirred and dissolved at room temperature under nitrogen protection for 5h to prepare a solution with a hydrogen ion concentration of 4.0mol / L;

[0043] (2) Separation: Use a vacuum filter to filter the solution prepared in step (1) to obtain 2810.7 g of the primary filtrate and 387.5 g of the primary filter residue, wash and filte...

Embodiment 3

[0051] (1) Dissolution: The lithium iron phosphate production waste with abnormal appearance (abnormal equipment, high sintering temperature) was taken for component analysis. The test results showed that the main components of the waste were: lithium 4.25wt%, iron 33.35wt%, phosphate radical 58.4wt% , carbon 2.41wt% and 1.59wt% other unavoidable trace elements, determine the effective molar weight of the waste material, that is, the molar weight of lithium iron phosphate, mix the waste material with the molar weight of 1:1.5 according to the effective amount and sulfuric acid, and weigh the waste material 645.50g, 600g of concentrated sulfuric acid with a wt% of 98 and 4000g of deionized water were stirred and dissolved at room temperature under nitrogen protection for 5 hours to prepare a solution with a hydrogen ion concentration of 2.0mol / L;

[0052] (2) Separation: Use a vacuum filter to filter the solution prepared in step (1) to obtain 3983.5 g of the primary filtrate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com