Mobile silage processing workshop and processing technology

A technology of silage and processing workshop, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of large collection and handling, scattered straw production and harvest, poor quality of silage, etc., and saves money. The effect of plant cost, reduction of manual labor workload, and strong freshness of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

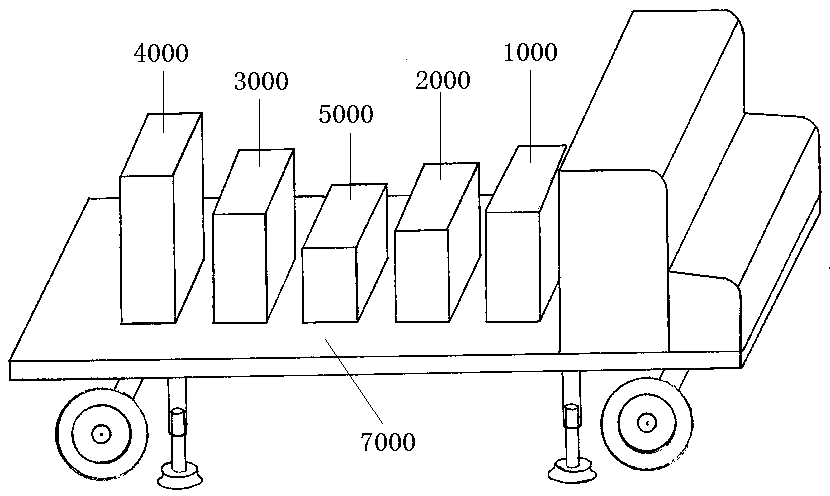

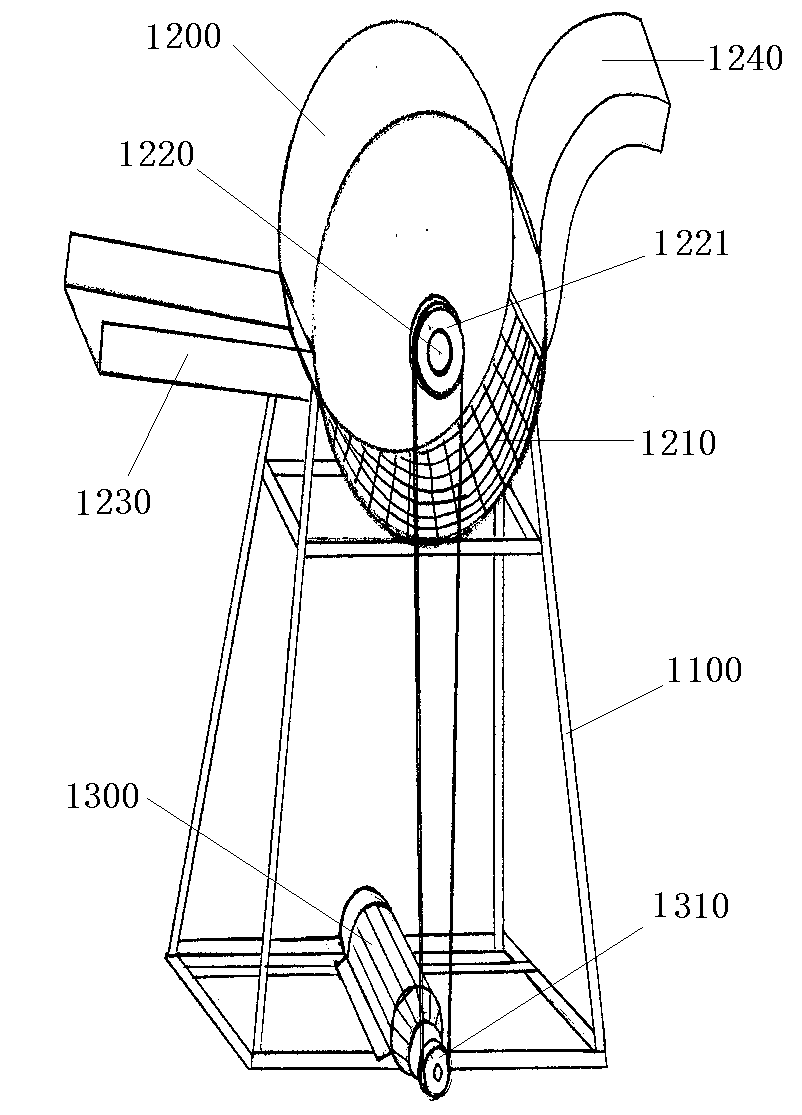

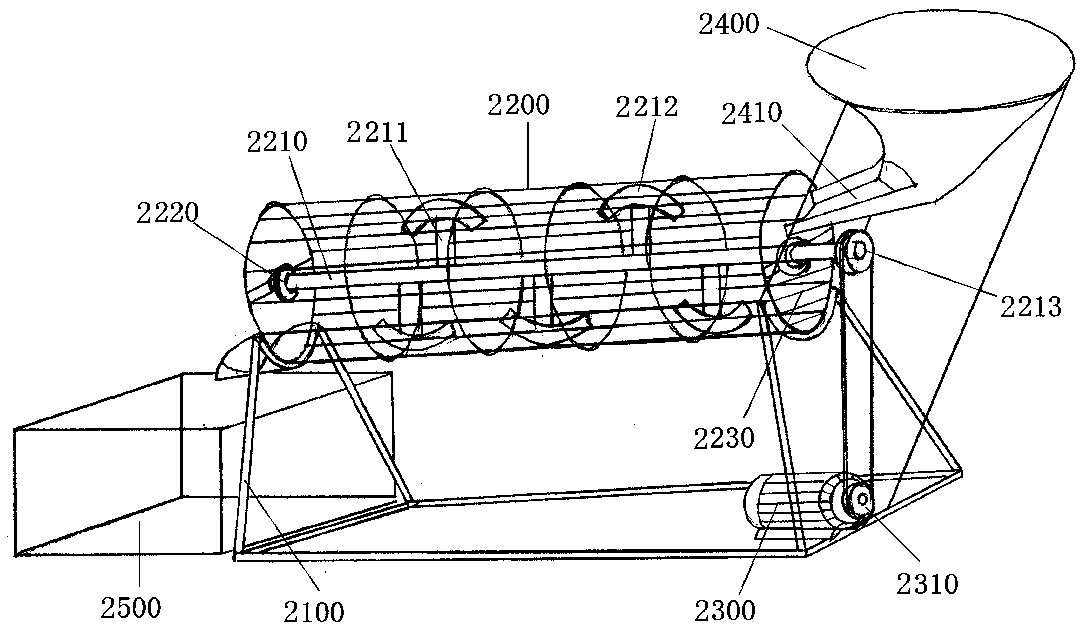

[0034] like Figure 1~10 As shown, a mobile silage processing workshop includes a carrying car body 7000, and the carrying car body is sequentially provided with a hollow cutting machine 1000, a rotary drum screen 2000, a straw kneading machine 3000 and a compression packaging machine from front to back. 4000, the side of the straw kneading machine is equipped with an additive sprayer 5000, and a screw conveyor 6000 is installed between the rotary drum sieve and the straw kneading machine and between the straw kneading machine and the compression packaging machine ( figure 1 not shown in ), the present invention can process crop stalks in a more timely manner, the freshness of raw materials is stronger, the quality of the silage produced is better, the palatability is better, the utilization rate is higher, and the effect of raising livestock is better; Reduce the workload of manual labor, reduce the cost of raw material collection, transportation and moving, save land and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com