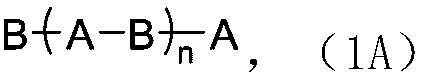

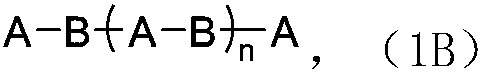

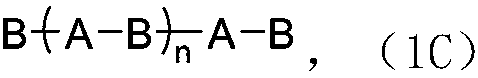

Flexible physical split-phase supramolecular dynamic polymer and application thereof

A polymer and supramolecular technology, applied in the production of bulk chemicals, etc., to achieve the effect of enhancing large deformation, enhancing energy dissipation, and large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0192] A preferred preparation method of a dynamic polymer ionic liquid gel of the present invention includes but is not limited to the following steps: blending the raw materials for preparing dynamic polymers with ionic liquids, so that the mass fraction of raw materials for preparing dynamic polymers is 0.5- 70%, polymerization, coupling or other types of chemical reactions are carried out through the appropriate means, and after the reaction is completed, a dynamic polymer ionic liquid gel is produced. The preferred preparation method of another dynamic polymer ionic liquid gel of the present invention includes but not limited to the following steps: the raw materials of the block polymer and the metal center are swollen in a solvent containing an ionic liquid, and the The mass fraction of the block polymer is 0.5-70%, and after fully swelling, the solvent is removed to form a dynamic polymer ion liquid gel. The block polymer molecule for preparing the ionic liquid gel is ...

Embodiment 1

[0253] Under the catalysis of dibutyltin dilaurate (DBTDL), diphenylmethane diisocyanate (MDI) and poly-β-hydroxybutyrate (average molecular weight about 3000Da) with equimolar equivalents of one terminal hydroxyl terminated in DMF were reacted to obtain Polyester terminated with isocyanate groups. Add 1 molar equivalent of polydimethylsiloxane (average molecular weight is about 10,000 Da) terminated with hydroxyl groups at both ends to the polyester solution containing 2 molar equivalents of isocyanate groups. After the reaction is complete, poly-β-hydroxybutyric acid is obtained. Ester-polydimethylsiloxane-poly-beta-hydroxybutyrate three-block polymer.

[0254] The obtained polymer and maleic anhydride were dissolved in chlorobenzene so that the initial mass volume concentration of maleic anhydride was 3%. Add benzoyl peroxide at 130°C so that the initial concentration of benzoyl peroxide is 0.2%, and keep the temperature for 6 hours to obtain a three-stage formula of modif...

Embodiment 2

[0258] Under anhydrous and oxygen-free conditions, 1 molar equivalent of azodimethyl N-2-hydroxybutylpropionamide is dissolved in toluene, and 105 molar equivalents of vinyl acetate are added. React for 16 hours at reflux temperature to obtain polyvinyl acetate with hydroxyl groups at both ends. The obtained polyvinyl acetate with hydroxyl groups at both ends is reacted with 2 molar equivalents of 4-pyridazine carboxylic acid under the catalysis of DCC and DMAP to obtain polyvinyl acetate with pyridazine ligand groups at both ends.

[0259] Under anhydrous and oxygen-free conditions, using AIBN as an initiator and elemental iodine as a chain transfer agent, the attenuation chain transfer polymerization of vinyl acetate is initiated to obtain polyvinyl acetate terminated with an iodine atom at one end. The obtained polyvinyl acetate is reacted with polyisobutene terminated by amino groups at both ends to obtain a polyvinyl acetate-polyisobutylene-polyvinyl acetate three-stage p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com