Polyacrylamide particle oil displacement agent and preparation method thereof

A polyacrylamide oil displacement agent, polyacrylamide technology, applied in the preparation and application of polymer materials, can solve the problems of oil displacement agent failure and achieve good oil displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The above step a is the preparation step of the crosslinking agent solution. The polyethylene polyamines include amines containing 2 to 4 ethylene groups and 2 to 5 primary or secondary amine groups, preferably having a longer chain structure with multiple primary or secondary amine groups (at least one primary amine, preferably all primary amines), such as tetraethylenepentamine, triethylenetetramine, diethylenetriamine, etc.

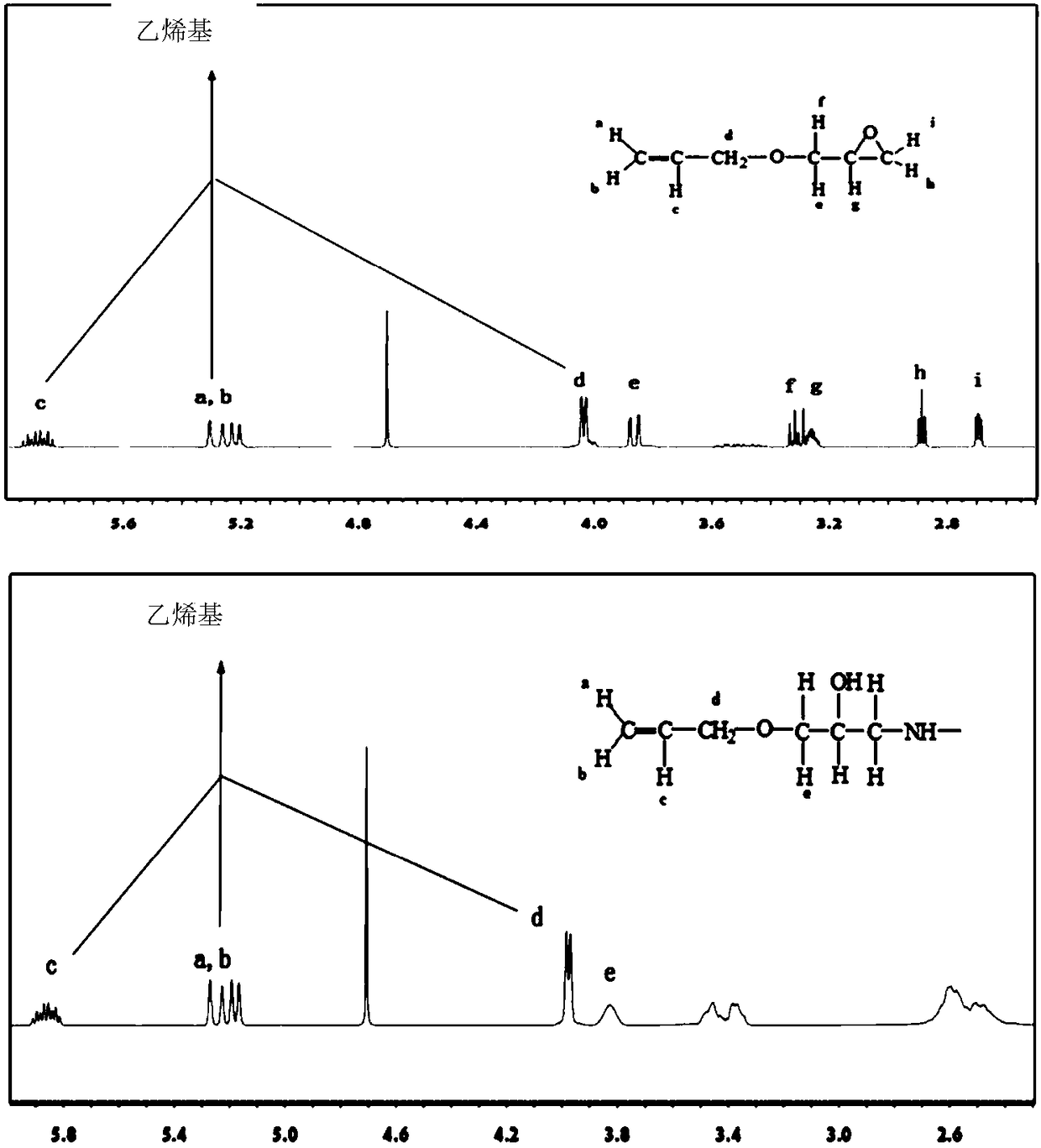

[0039] The reaction of polyethylene polyamine with allyl glycidyl ether or glycidyl (meth)acrylate in aqueous solution is a ring-opening addition reaction. Take the reaction of allyl glycidyl ether and tetraethylenepentamine as an example, such as from figure 1 It can be seen that the two hydrogen atoms on the allyl glycidyl ether molecule with different chemical environments from the adjacent carbons of the ether bond become two hydrogen atoms with the same chemical environment after reacting with tetraethylenepentamine and move to the downfie...

Embodiment A

[0069] Example A: Dissolve tetraethylenepentamine and allyl glycidyl ether with a molar ratio of 1:4 in 100 parts of water, adjust the mass fraction of the solute to 6.54%, and prepare the prepared reactant in a condenser equipped with In the reaction device of temperature controller and stirrer, react at 75° C. for 6 hours to prepare multifunctional crosslinking agent solution A.

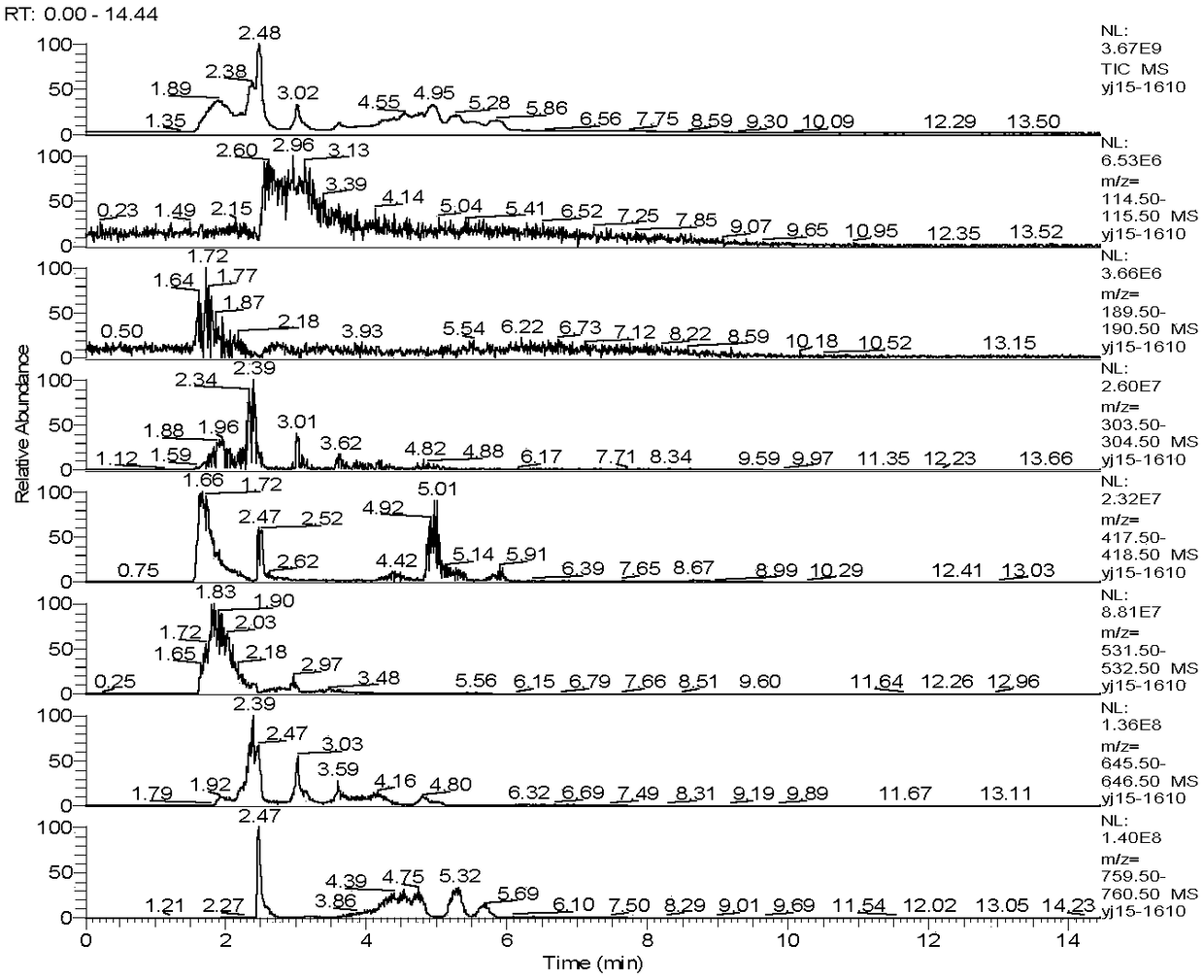

[0070] The H NMR spectra of the reactant allyl glycidyl ether and the reaction product are as follows: figure 1 Shown, the liquid chromatography-mass spectrometry test result of gained cross-linking agent is as follows figure 2 shown. The proton nuclear magnetic resonance spectrum was carried out on the AV600 model NMR instrument of Bruker Company, and the liquid chromatography-mass spectrometry was carried out on the 1100MSD model chromatograph-mass spectrometry instrument of Aqilent Company, and the chromatographic conditions were: a reversed-phase silica gel column was used, and the mobile pha...

Embodiment B

[0071] Example B: Tetraethylenepentamine and allyl glycidyl ether with a molar ratio of 1:4 were dissolved in 100 parts of water, and the mass fraction of the solute was adjusted to 6.54%, and the prepared reactant was equipped with a condenser, In the reaction device of temperature controller and stirrer, react at 50°C for 6 hours to prepare multifunctional crosslinking agent solution B

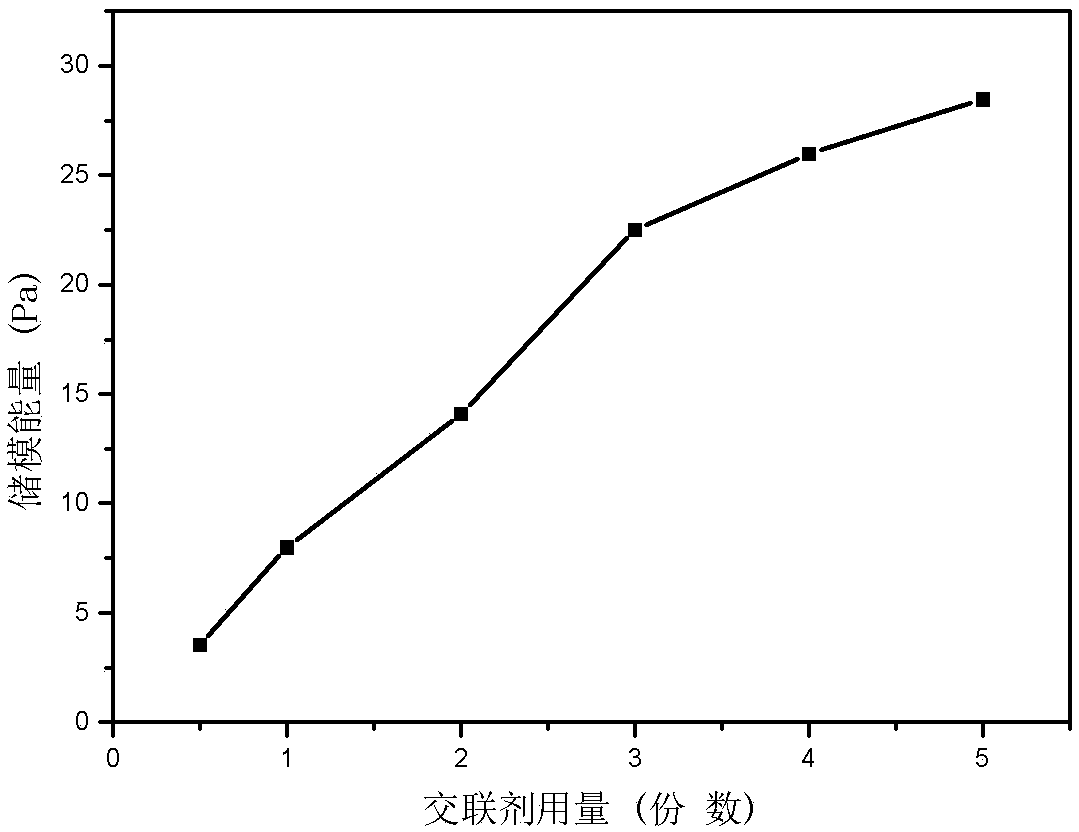

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com