Vanadium extraction method of high calcium and high phosphorus vanadium slag

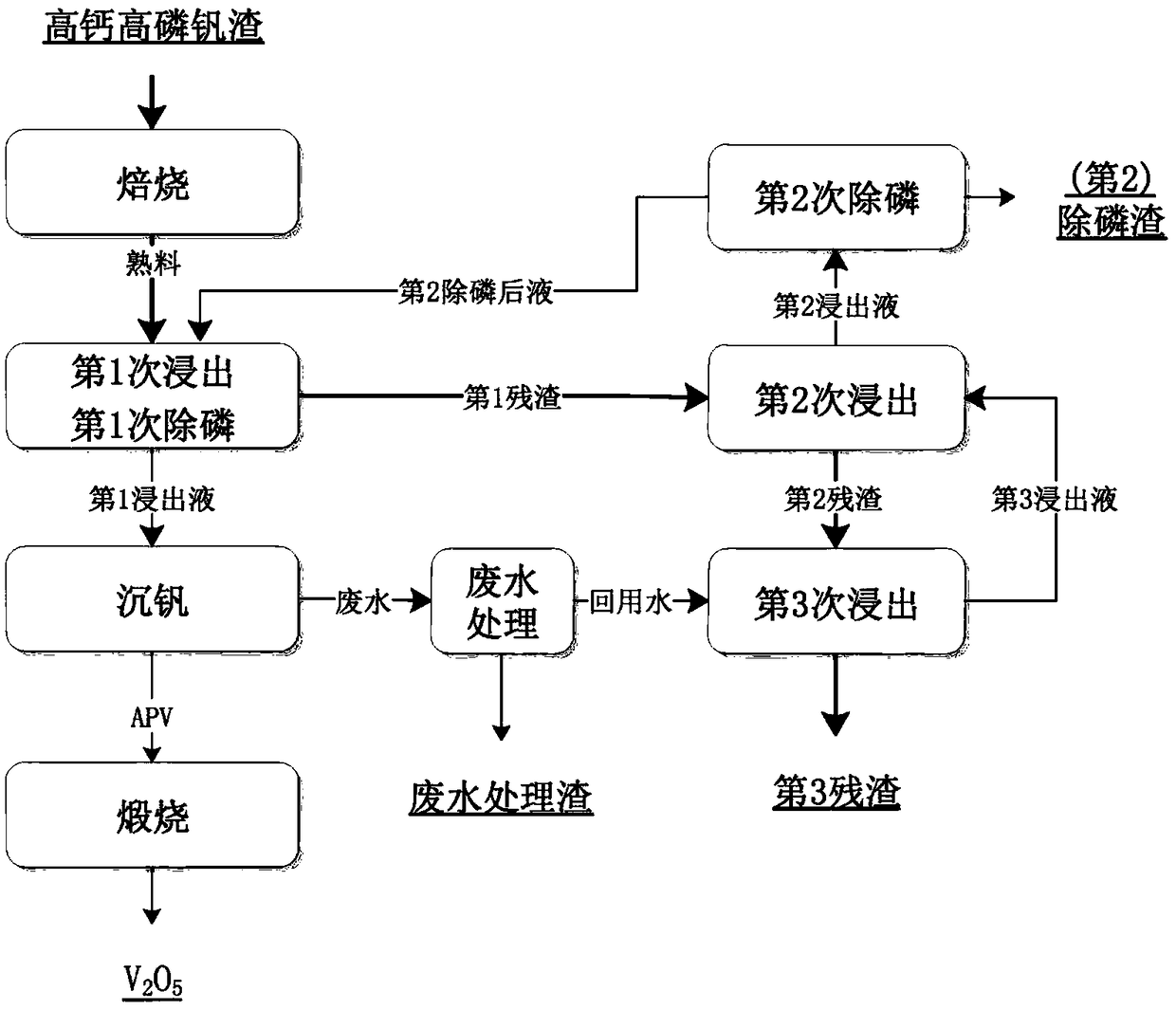

A high-calcium and high-phosphorus vanadium slag and vanadium precipitation technology is applied in the direction of improving process efficiency, which can solve the problems of high cost, difficulty in recovering vanadium from the second acid leaching solution, and difficulty in realizing industrialization, and achieves a short technological process. , the effect of less investment and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1 adopts the inventive method to extract vanadium from high-calcium and high-phosphorus vanadium slag

[0084] The high calcium and high phosphorus vanadium slag (V 2 o 5 =10.71%, CaO=6.75%, P=0.38%), ground to a particle size of less than 0.12mm, placed in an air-filled muffle furnace, heated to 890°C and kept for 90min, taken out and cooled to make a sample below 0.12mm.

[0085] Take 100g of the clinker after sample preparation for acid leaching (first-stage leaching), 300mL of mother liquor, control the pH of the system with sulfuric acid to 3.0-3.2 under stirring conditions, and leaching for 45min at a temperature of 55°C, add to the first leaching solution 0.5g of polymerized ferric sulfate (the first stage of phosphorus removal), and then stirred for 5 minutes to separate the liquid and solid to obtain a vanadium-containing liquid. The measured TV=32.86g / L and P=0.025g / L in the vanadium-containing liquid.

Embodiment 2

[0093] Embodiment 2 adopts the method of the present invention to extract vanadium from high-calcium and high-phosphorus vanadium slag

[0094] The high calcium and high phosphorus vanadium slag (V 2 o 5 =14.52%, CaO=10.16%, P=0.74%), ground to a particle size of less than 0.12mm, placed in an air-filled muffle furnace, heated to 900°C and kept for 60min, taken out and cooled to make a sample below 0.12mm.

[0095] Take 100g of clinker after sample preparation for acid leaching (first-stage leaching), 300mL of mother liquor, use sulfuric acid to control the system pH=3.0-3.3 under stirring conditions, and leaching for 60min at a temperature of 68°C, add 0.65g of polymerized ferric sulfate (the first stage of phosphorus removal), and then stirred for 10 minutes to separate the liquid and solid to obtain a vanadium-containing liquid. It was measured that TV=36.73g / L and P=0.022g / L in the vanadium-containing liquid.

[0096] Add ammonium sulfate to the vanadium-containing liqui...

Embodiment 3

[0103] Embodiment 3 adopts the method of the present invention to extract vanadium from high-calcium and high-phosphorus vanadium slag

[0104] The high calcium and high phosphorus vanadium slag (V 2 o 5 =12.75%, CaO=8.91%, P=0.50%), ground to a particle size of less than 0.12mm, placed in an air-filled muffle furnace, heated to 900°C and kept for 60min, taken out and cooled to make a sample below 0.12mm.

[0105] Take 100g of clinker after sample preparation for acid leaching (first-stage leaching), 300mL of mother liquor, control system pH=3.2-3.5 with sulfuric acid under stirring condition, and leaching for 60min at 45°C, add to the first leaching solution 0.4g of polymerized ferric sulfate (the first stage of phosphorus removal), and then stirred for 5 minutes, liquid-solid separation to obtain a vanadium-containing liquid, measured TV = 34.59g / L, P = 0.025g / L in the vanadium-containing liquid.

[0106] Add ammonium sulfate to the vanadium-containing liquid at a mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com