A polymer-protected lithium anode and a preparation method thereof

A polymer, lithium anode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve the problems of lithium dendrite piercing the diaphragm, high interface impedance, uneven deposition, etc., to improve cycle stability , The effect of improving interface adhesion and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

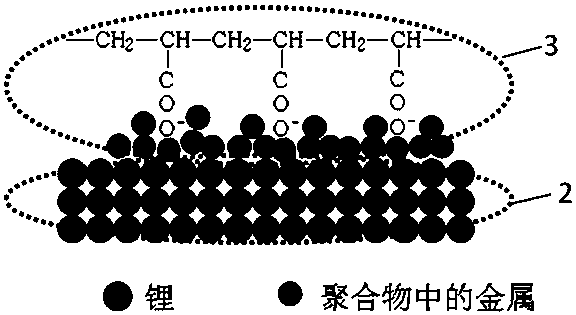

[0015] Specific Embodiment 1: This embodiment describes a lithium negative electrode protected by a polymer. The lithium negative electrode includes a current collector 1, and the two opposite sides of the current collector 1 are each provided with a lithium-containing material layer 2, each The outer surfaces of each lithium-containing material layer 2 are coated with a polymer 3 . figure 2 It is a schematic diagram of the microstructure between the lithium-containing material layer 2 and the polymer 3, because the metal contained in the polymer 3 will be precipitated on the surface of the lithium-containing material layer 2 during the charging process and act as a skeleton structure to enhance the stability of the interface structure, and This microstructure will enhance the adhesion of the polymer film on the surface of the lithium-containing material layer 2 .

specific Embodiment approach 2

[0016] Embodiment 2: The polymer-protected lithium negative electrode described in Embodiment 1, the material of the current collector 1 is copper foil, copper mesh, copper foam, nickel foam, carbon fiber film or graphene film, The thickness is 1~100μm.

specific Embodiment approach 3

[0017] Embodiment 3: The polymer-protected lithium negative electrode described in Embodiment 1, the material of the lithium-containing material layer 2 is pure lithium, lithium aluminum alloy, lithium magnesium alloy, lithium boron alloy, lithium indium alloy , Lithium-carbon composite material or lithium-silicon composite material, with a thickness of 0.1-100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com