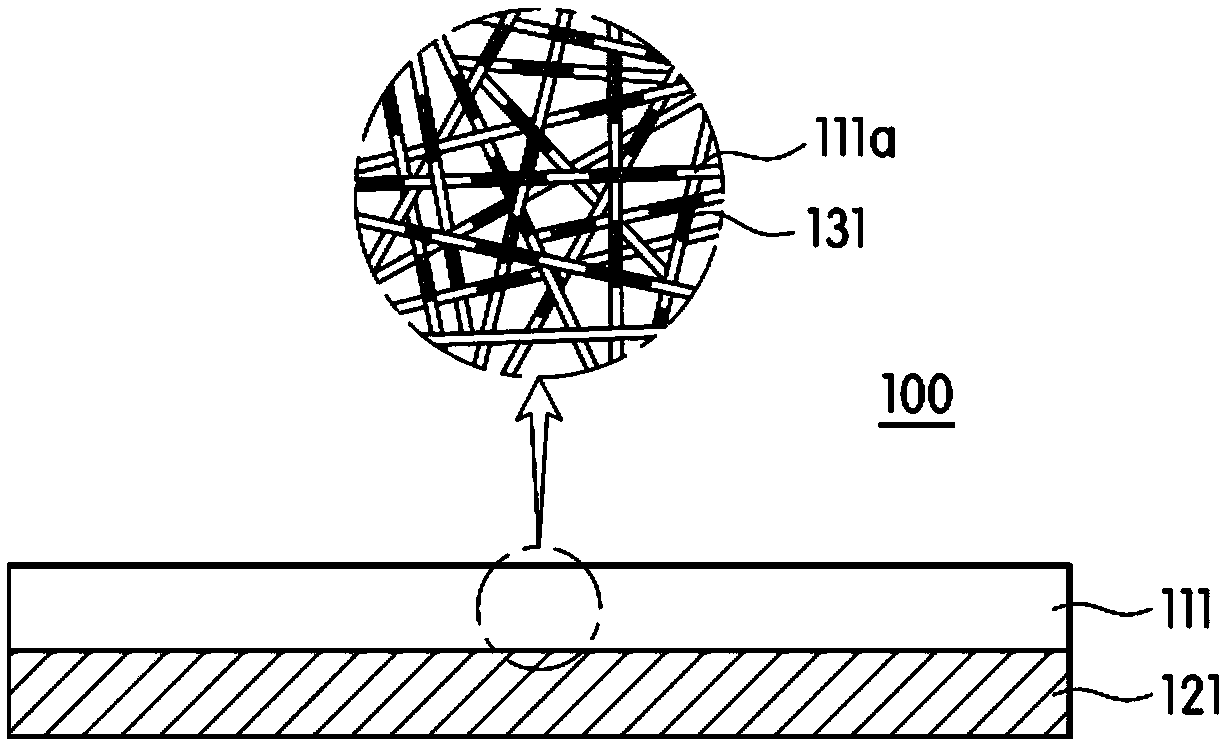

Filter medium, method for manufacturing same, and filter module comprising same

A filter medium and manufacturing method technology, applied in membrane filters, separation methods, filtration and separation, etc., can solve the problems of inability to increase flow, easy disappearance of hydrophilicity, poor permeability, etc., to prolong the service life and improve the hydrophilicity. , improve the effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

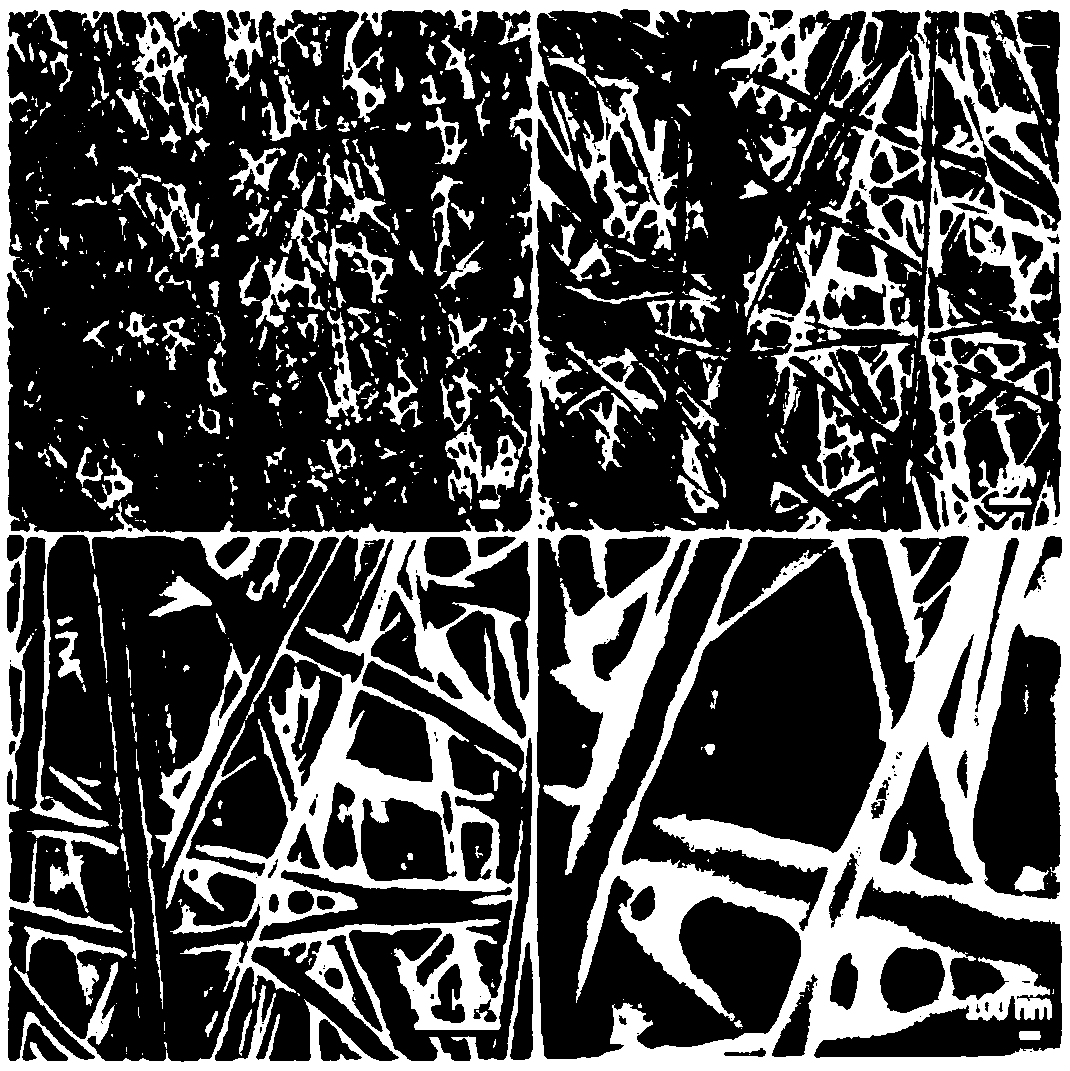

[0095] First, in order to prepare a spinning solution, in 88 g of a mixed solvent obtained by mixing dimethylacetamide and acetone at a weight ratio of 70:30, 12 g of polyfluorescein, which is a fiber-forming component, was melted at a temperature of 80° C. using a magnetic bar. Ethylene difluoride (Arkema, Kynar 761) was dissolved for 6 hours to prepare a mixed solution. The above-mentioned spinning solution was put into the solution tank of the electrospinning device, and discharged at a rate of 15 μl / min / hole. At this time, the temperature in the spinning zone was kept at 30° C., the humidity was kept at 50%, and the distance between the collector and the tip of the spinning nozzle was 20 cm. Then, a voltage of more than 40kV was applied to the spinning nozzle assembly (SpinNozzle Pack) using a high voltage generator, and an air pressure of 0.03MPa was applied to each spinning assembly nozzle to prepare a fiber web layer formed by PVDF nanofibers. Then, in order to dry the...

Embodiment 2~ Embodiment 18

[0101] Except changing the component etc. of hydrophilic coating composition as shown in following table 1, table 2 or table 3, all the other make the filter medium shown in following table 1, table 2 or table 3 in the same way as embodiment 1 .

experiment example 1

[0105] The following physical properties of the filter media according to Examples and Comparative Examples were evaluated, and the results are shown in Tables 1 to 3 below.

[0106] 1. Measuring the wetting angle

[0107]A contact angle (Contact angle, °) measuring device is used to measure the contact angle formed by the surface of the fiber web layer and the surface of the water drop to measure the wettability (wettability) of water on the exposed surface of the fiber web layer. A method of photographing the shape of a droplet with a CCD camera and calculating the interfacial tension γ optimized for the last photographed droplet shape was used. Adjust the injection volume to 0.05 mL via a microsyringe and use double distilled water. The contact angle was measured within 20 seconds after the droplet was formed at five points on the surface of the fiber web layer, and the average value thereof and the average deviation according to Mathematical Formula 1 above were calculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com