Cherry-flavored nano fishbone granule biscuit and making method thereof

A fishbone and nanotechnology, applied in baking, baked goods with modified ingredients, dough processing and other directions, can solve the problems of low vitamin D content, inconvenient eating, low content, etc., and achieve less loss of nutrients and less consumption. Convenience and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

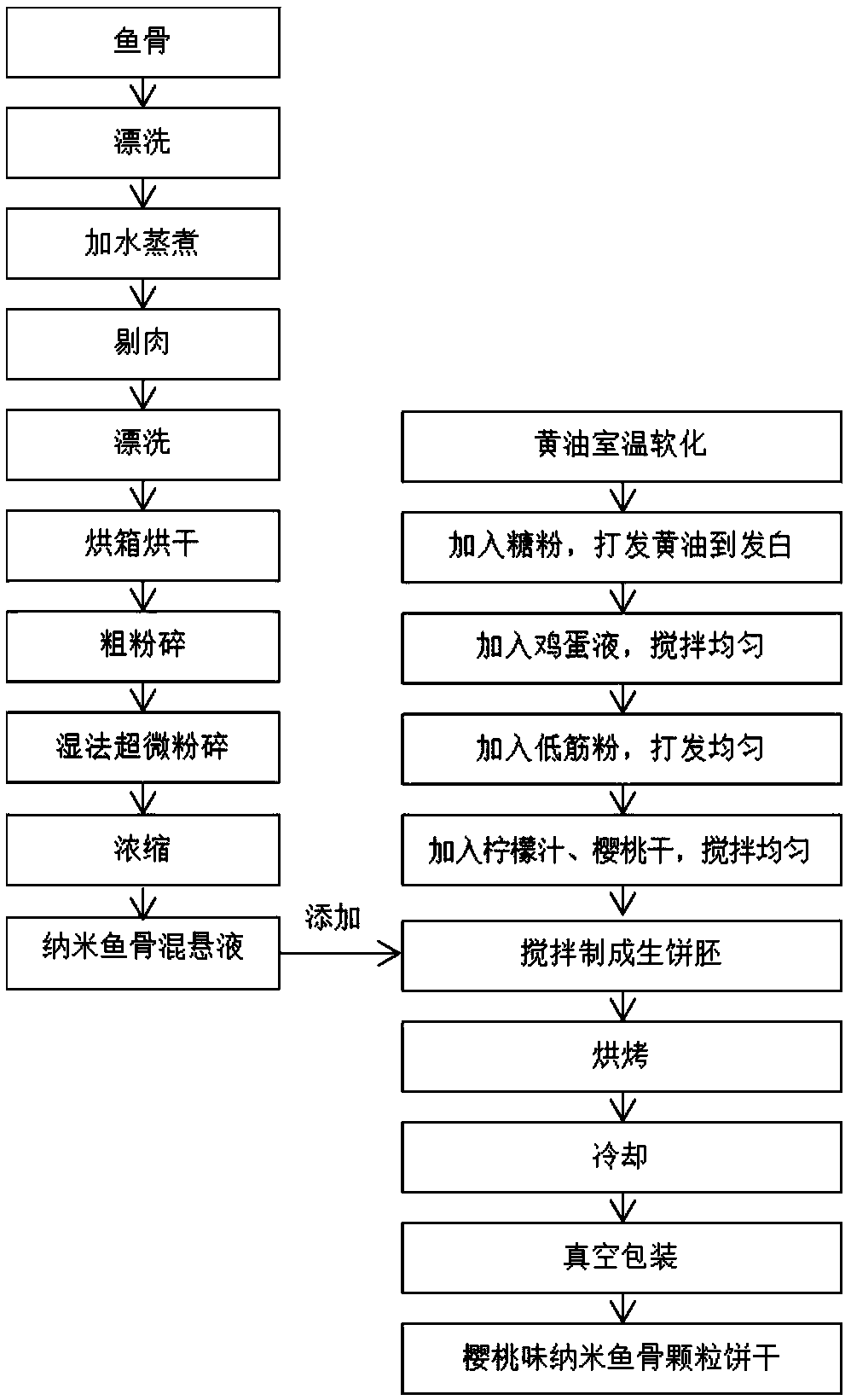

Method used

Image

Examples

Embodiment 1

[0030] Preparation of nano-fishbone particle suspension: clean the thawed fishbone, add water to cover the fishbone in a cooking pot, pour off the water after boiling for 5 minutes, remove the fish meat on the fishbone, rinse and put in the oven Dry at a temperature of 60°C, put it into a high-speed pulverizer for coarse pulverization, the pulverization time is 10 minutes, and then use wet ball milling, the working conditions are 2000rpm, the size of the grinding medium is 1cm, the filling volume of the medium is 30%, and the ball milling time is 12h , to prepare nanoparticles, cook at 100° C. for 2 hours and concentrate to prepare a suspension of high-concentration nano-fishbone particles with a concentration of 67% (mass of nano-fishbone particles: volume ratio of solution);

[0031] Preparation of cherry-flavored nano fishbone biscuits: soften 14 parts of butter at room temperature, add 15 parts of powdered sugar, beat the butter until it turns white, add 13 parts of egg liq...

Embodiment 2

[0033] Preparation of nano-fishbone particle suspension: clean the thawed fishbone, add water to cover the fishbone in a cooking pot, pour off the water after boiling for 5 minutes, remove the fish meat on the fishbone, rinse and put in the oven Dry at a temperature of 60°C, put it into a high-speed pulverizer for coarse pulverization, and the pulverization time is 10 minutes, and then use an ultrafine pulverizer for wet pulverization. The particles were concentrated by steaming at 100°C for 2 hours to prepare a suspension of high-concentration nano-fishbone particles with a concentration of 75% (mass of nano-fishbone particles: solution volume ratio);

[0034] Preparation of cherry-flavored nano fishbone biscuits: soften 18 parts of butter at room temperature, add 20 parts of powdered sugar, beat the butter until it turns white, add 14 parts of egg liquid, score evenly, add 35 parts of low-gluten flour, stir well, and add in order Concentrated nano-fishbone particle solution, 2...

Embodiment 3

[0036] Preparation of nano fishbone particle suspension: clean the fresh fishbone, add water in a cooking pot to cover the fishbone, pour off the water after boiling for 5 minutes, remove the fish meat on the fishbone, rinse, put into the oven for 50 Dry at ℃, put it into a high-speed pulverizer for coarse pulverization, the pulverization time is 15min, and then use wet ball mill pulverization, the working condition is 2000rpm, the size of the grinding medium is 0.5cm, the filling volume of the medium is 50%, and the ball milling time is 12h. The nanoparticles are prepared, and the supernatant is discarded at 40000g ultra-high speed centrifugation, the lower layer is precipitated and an appropriate amount of liquid is vortexed, and a high-concentration nano-fishbone particle suspension is prepared, and the concentration is 85% (nano-fishbone particle mass: solution volume ratio );

[0037] Preparation of cherry-flavored nano-fishbone biscuits: soften 13-18 parts of butter at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com