Modified attapulgite filter material for heavy metal wastewater treatment and preparation method of modified attapulgite filter material

A modified attapulgite and wastewater treatment technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of unsatisfactory effect, limited adsorption capacity, and influence on attapulgite Application and other issues, to achieve the effect of improving treatment effect, easy biodegradability, and enhancing chelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

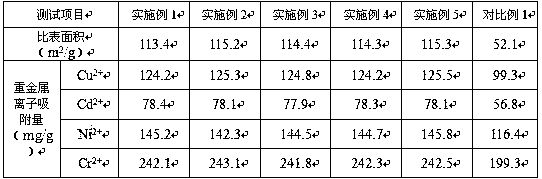

Examples

Embodiment 1

[0030] a. Add attapulgite powder into water, stir evenly, add silane coupling agent γ-aminopropyltriethoxysilane to it, and filter after ultrasonic dispersion treatment. The ultrasonic frequency of ultrasonic dispersion is 42kHz, and the time is 28min , vacuum drying, the temperature of vacuum drying is 76 ° C, and the time is 11 hours to obtain modified attapulgite; wherein, 16 parts by weight of attapulgite powder, 83 parts by weight of water, and 1 part by weight of silane coupling agent;

[0031] B, the modified attapulgite prepared in step a is uniformly mixed with tetrasodium iminodisuccinate to prepare the mixture; wherein, the mass ratio of modified attapulgite and tetrasodium iminodisuccinate is 13: 1;

[0032] c. Add the mixture prepared in step b into the silica sol, send it to a granulator for granulation, and pass through a 10-mesh sieve to obtain a modified attapulgite filter material for heavy metal wastewater treatment, wherein the mixture is 48 parts by weight...

Embodiment 2

[0034] a. Add attapulgite powder into water, stir evenly, add silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane to it, filter after ultrasonic dispersion treatment, the ultrasonic frequency of ultrasonic dispersion is 30kHz, time For 40 minutes, vacuum drying, the temperature of vacuum drying is 70 ° C, and the time is 12 hours, to obtain modified attapulgite; wherein, 10 parts by weight of attapulgite powder, 89 parts by weight of water, and 1 part by weight of silane coupling agent;

[0035] B, the modified attapulgite prepared in step a is uniformly mixed with tetrasodium iminodisuccinate to prepare the mixture; wherein, the mass ratio of modified attapulgite and tetrasodium iminodisuccinate is 10: 1;

[0036] c. Add the mixture prepared in step b into the silica sol, send it to a granulator for granulation, pass through a 20-mesh sieve, and obtain a modified attapulgite filter material for heavy metal wastewater treatment, wherein 40 parts by weight of the m...

Embodiment 3

[0038]a. Add attapulgite powder into water, stir evenly, add silane coupling agent γ-methacryloxypropyltrimethoxysilane to it, and filter after ultrasonic dispersion treatment. The ultrasonic frequency of ultrasonic dispersion is 50kHz , the time is 20min, vacuum drying, the temperature of vacuum drying is 80 ℃, and the time is 8h, and the modified attapulgite is obtained; wherein, 20 parts by weight of attapulgite powder, 78 parts by weight of water, and 2 parts by weight of silane coupling agent ;

[0039] B, the modified attapulgite obtained in step a is uniformly mixed with tetrasodium iminodisuccinate to prepare a mixture; wherein, the mass ratio of modified attapulgite and tetrasodium iminodisuccinate is 15: 1;

[0040] c, adding the mixture prepared in step b to silica sol, sending it into a granulator for granulation, and passing through a 10-mesh sieve to obtain a modified attapulgite filter material for heavy metal wastewater treatment, wherein 60 parts by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com