Photocatalytic nitrogen-fixation Zn-doped indium oxide photocatalyst material as well as preparation method and application thereof

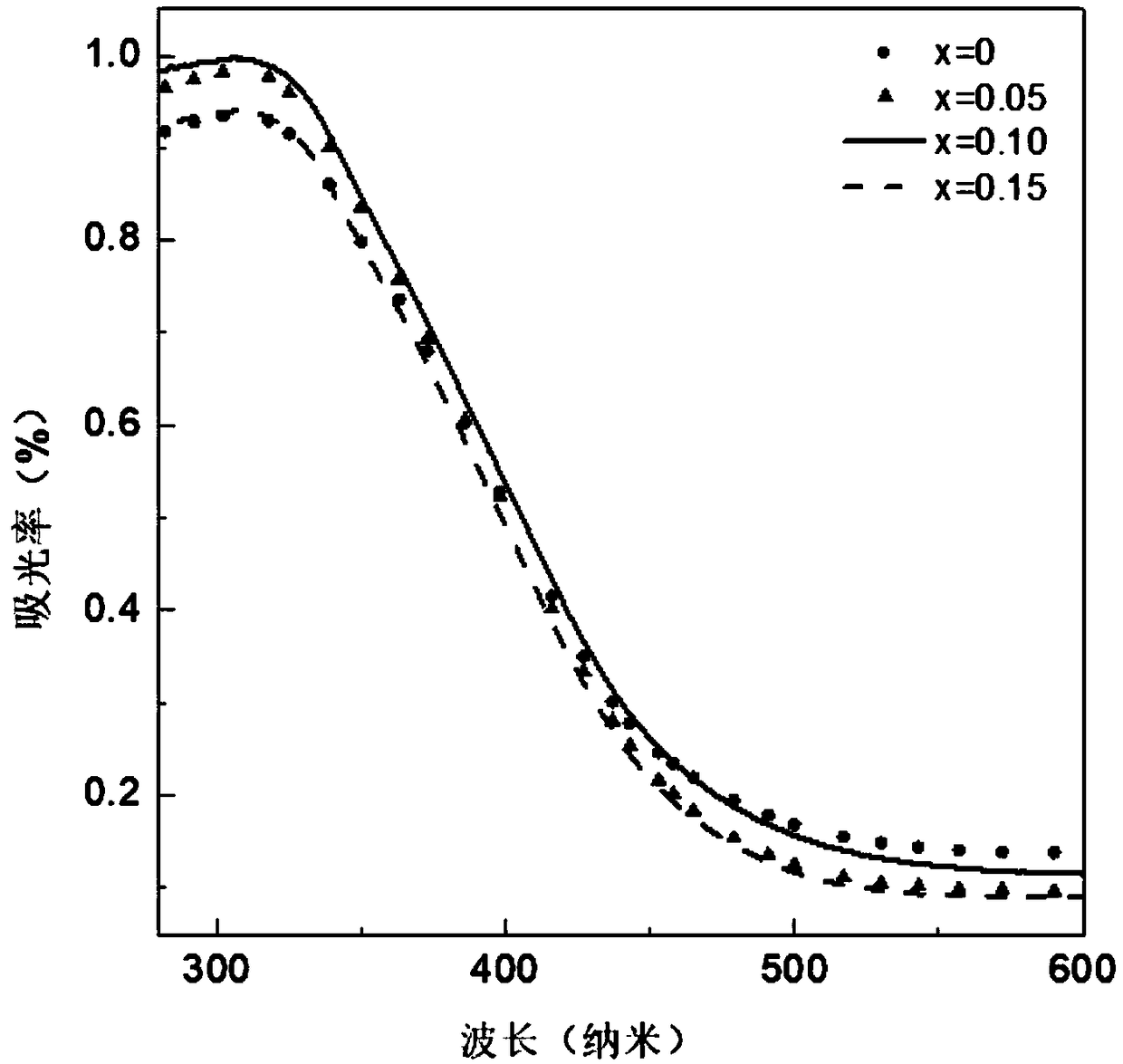

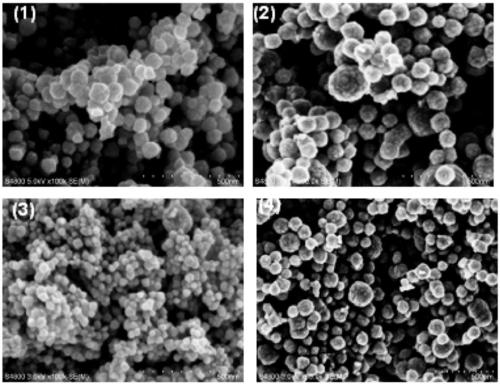

A photocatalyst and photocatalytic technology, applied in chemical instruments and methods, ammonia preparation/separation, physical/chemical process catalysts, etc., can solve the problem that the dissociation ability cannot meet the requirements, it is difficult to produce and apply on a large scale, and the utilization rate of sunlight is low and other problems, to achieve the effect of beautiful and efficient spherical shape, sensitive visible light response, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0025] A kind of preparation method of photocatalytic nitrogen fixation Zn doped indium oxide photocatalyst material, concrete steps are:

[0026] Preparation of carbon sphere template:

[0027] Add 6g of glucose into deionized water, stir until fully dissolved, transfer to a hydrothermal kettle at 180°C, react for 24 hours, wash and dry to obtain conventional carbon spheres; continue to place conventional carbon spheres in ammonia atmosphere, 300°C Treat for 3 hours to obtain ammonia-treated carbon spheres.

[0028] Synthesize Zn-doped In according to Table 1 2 o 3

[0029] Dissolve zinc acetate dihydrate and indium chloride tetrahydrate in 100ml N,N-dimethylformamide, stir for a few minutes, add ammonia to treat the carbon spheres, ultrasonicate for half an hour to disperse the carbon spheres evenly, then transfer to the hydrothermal reaction kettle In the process, the hydrothermal reaction was carried out at 180°C for 6 hours. After the reaction was completed, after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com