MOX-coated NH2-MOFs thin film material as well as preparation method and application thereof

A thin film material and thin film technology, applied in the field of MOX@NH2-MOFs thin film material and its preparation, can solve the problems such as the inability to obtain ultra-fast response and recovery of gas sensors, the difficulty of rapid recovery of room temperature sensors, and the easy recombination of electron holes. Achieve high selectivity and high sensitivity rapid detection, overcome low selectivity and low sensitivity, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] a TiO 2 The preparation method of the film includes the following steps:

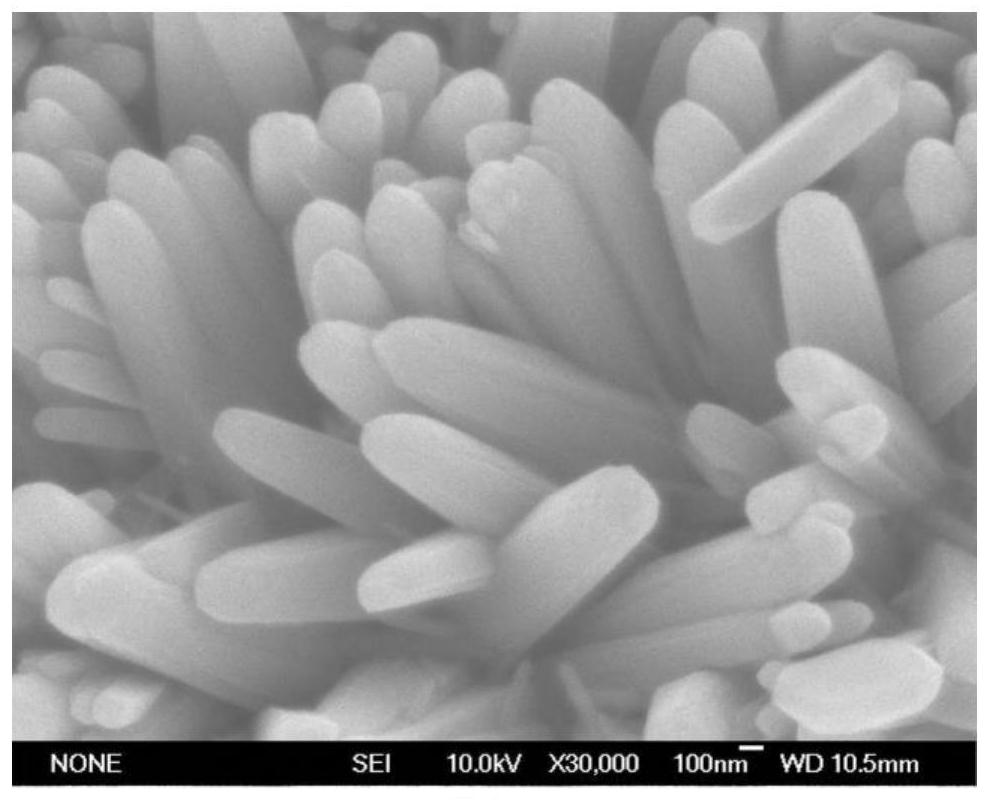

[0057] Dissolve tetra-n-butyl titanate in ethanol, then immerse the clean sapphire substrate in ethanol solution dissolved in tetra-n-butyl titanate for 3 hours, then take it out directly, rinse with ethanol, dry naturally, and then 450 ℃ After calcination for 30min, a layer of TiO 2 A seed layer substrate composed of nanoparticles. Then fix the substrate face down in the Teflon liner, mix 6ml of hydrochloric acid with 6ml of deionized water, add 0.4ml of tetra-n-butyl titanate, and then add it to the Teflon liner together, and finally Tightly cover the inner lining, put it into a stainless steel autoclave, put the autoclave in an oven, keep it at 150°C for 4 hours, take out the substrate, rinse it with ethanol, dry it naturally, and calcine it at 450°C for 30 minutes to obtain a sapphire substrate. by TiO 2 The thin film composed of nanowire arrays, the SEM image is as follows figure 1 sho...

Embodiment 2

[0059] A SnO 2 The preparation method of the film includes the following steps:

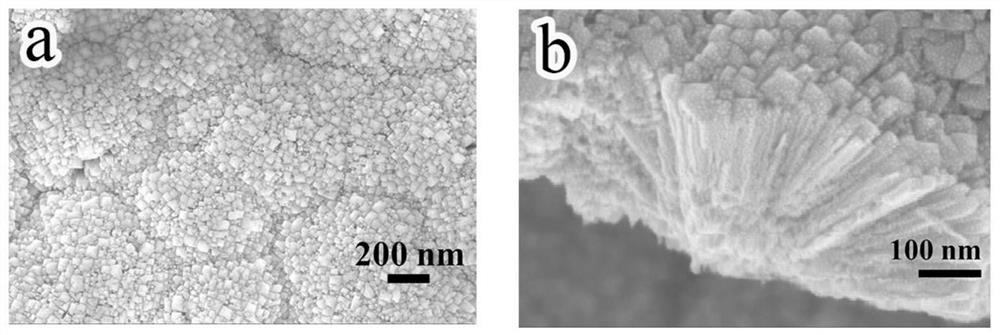

[0060] The first solution was obtained by dissolving 3 mmol (357 mg) of KBr in 10 ml of deionized water. 1 mmol (350.6 mg) SnCl 4 .5H 2 O was dissolved in 60 ml of acetic acid to obtain a second solution. The first solution and the second solution were then mixed, and 10 ml of ethanol was added to obtain a third solution. Put the third solution into a teflon liner, add a cut glass slide of 1cm x 2cm, put the liner into a steel sleeve, put it in an oven at 200°C, and the solvent reacts. 24 hours to get SnO 2 film, whose SEM image is as figure 2 shown, is a continuous SnO consisting of an array of nanowires 2 The film is white, has good ultraviolet light absorption, has very obvious photoconductivity under ultraviolet light, and has a fast response speed.

Embodiment 3

[0062] A SnO 2 The preparation method of the film includes the following steps:

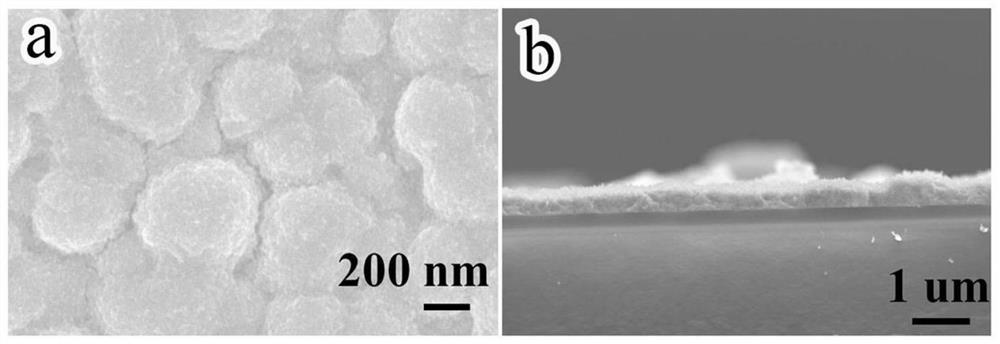

[0063] The first solution was obtained by dissolving 3 mmol (357 mg) of KBr in 10 ml of deionized water. 1 mmol (350.6 mg) SnCl 4 .5H 2 O was dissolved in 60 ml of acetic acid to obtain a second solution. The first solution and the second solution were then mixed, and 10 ml of ethanol was added to obtain a third solution. Then, 0.2 mmol Sn powder was added into the third solution to obtain the fourth solution. Then put the fourth solution into the teflon lining, add a cut glass slide of 1 cm × 2 cm, put the lining in the steel sleeve, put it in an oven at 200 ° C, the solvent Reaction for 24 hours to obtain SnO 2 film, whose SEM image is as image 3 shown. from image 3 It can be seen that after adding Sn powder, the morphology changed from the nanowire array in Example 2 to continuous and dense nanoparticles. The color of the powder scraped from the substrate also changed from white in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com