A kind of nitrogen oxide nanoparticle photocatalyst and its application

A nitrogen oxide and nanoparticle technology, applied in the field of photocatalytic materials, can solve the problems of poor stability, inability to effectively absorb visible light, low solar light absorption rate, etc., and achieve good monodispersity, excellent solar photocatalytic water splitting system. Hydrogen and photodegradation of formaldehyde, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

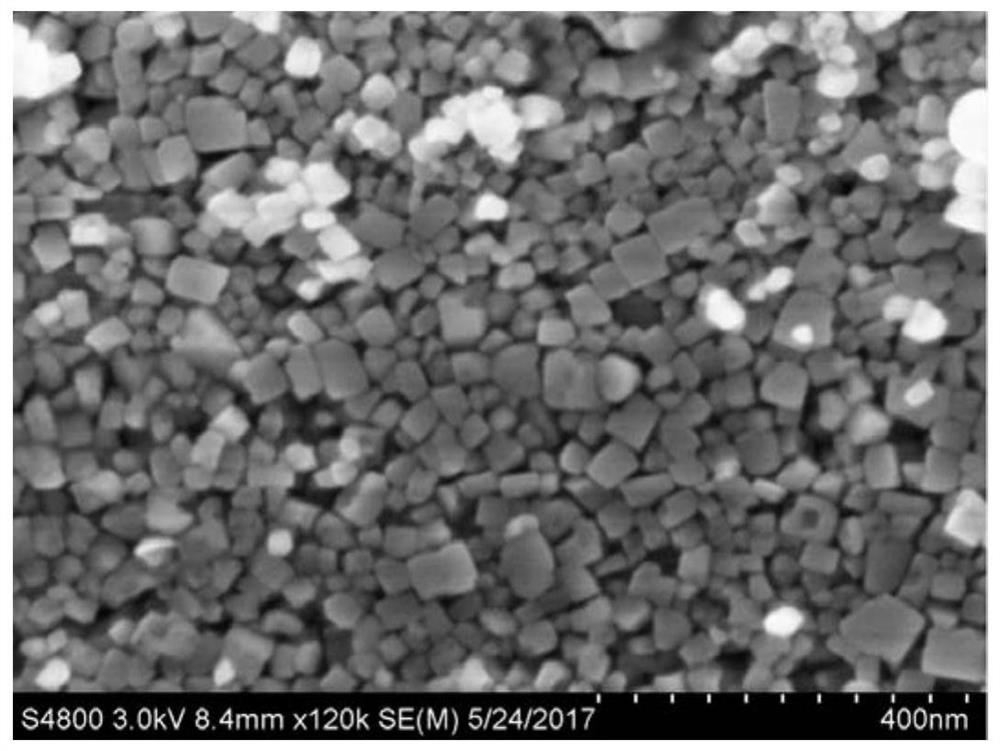

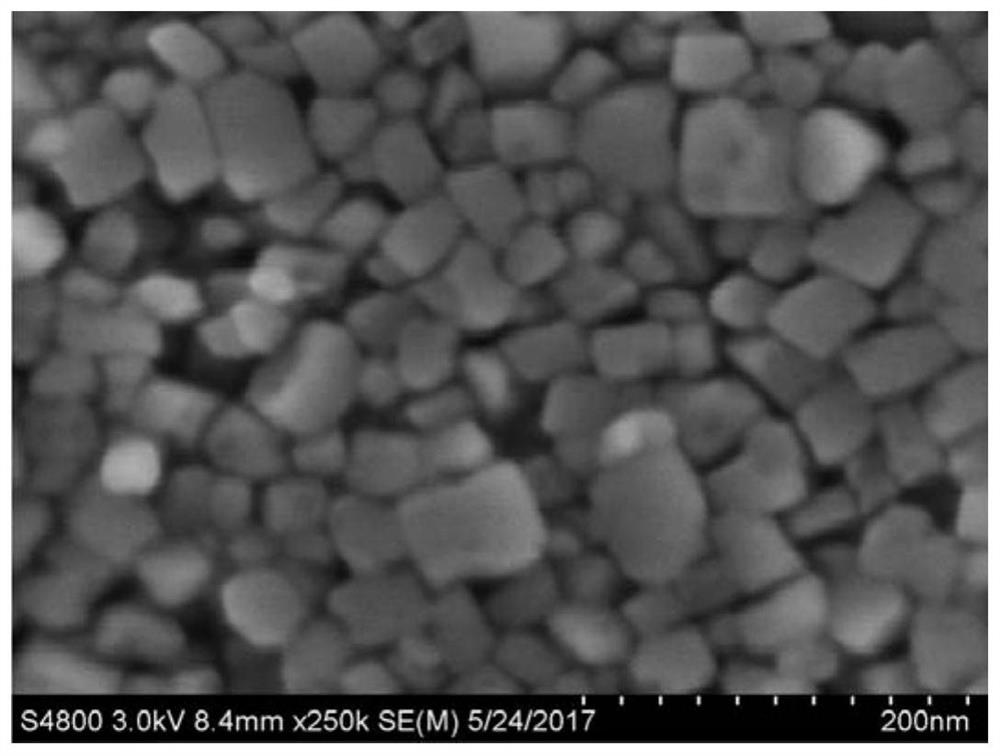

[0031] Ta 3 N 5 Preparation and performance testing of nanoparticles

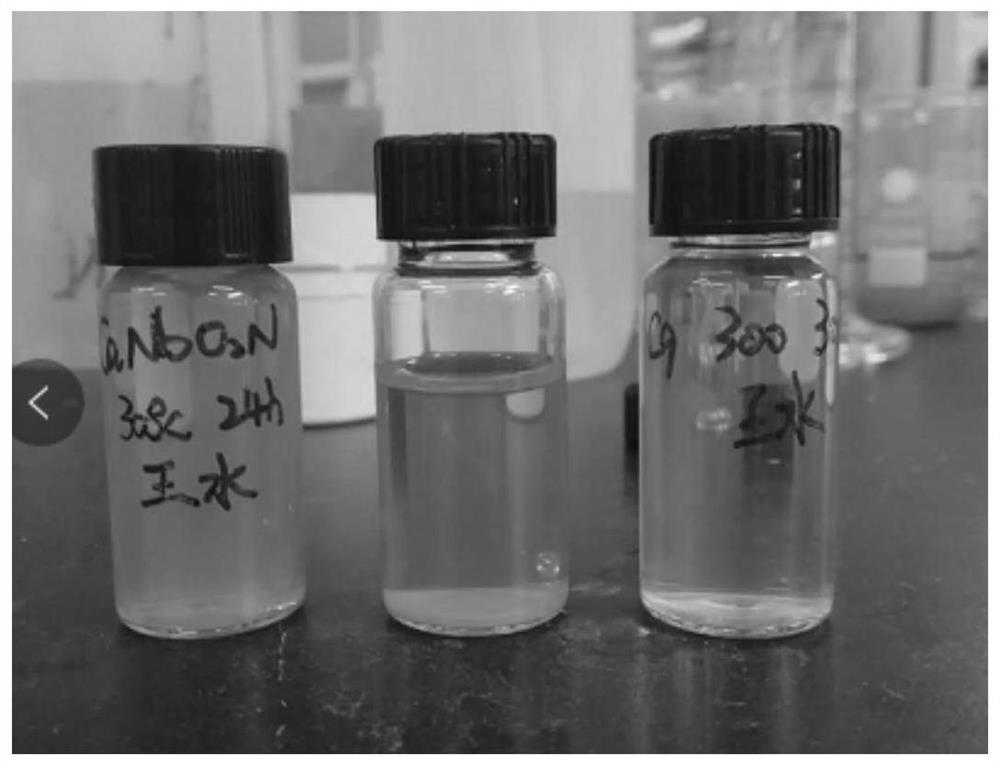

[0032] Under the condition of temperature at 298K, tantalum pentachloride ethanol solution (1g tantalum pentachloride, 5mL ethanol) was dissolved in 100mL deionized water to obtain transparent solution S1; 20g of sodium hydroxide was dissolved in 100mL deionized water, Obtain a transparent solution S2; add the S2 solution dropwise to the stirred S1 solution at a rate of 30 drops per minute, from the beginning to the end of the stirring, the whole process time is 4 hours, and the product is a flocculent white oxide, Wash with deionized water until the pH value is neutral, and place it in an oven to obtain the metal oxide precursor powder P1; the powder P1 is placed in an alumina crucible, and under the protection of an ammonia atmosphere, it is burned at 1223K for 5 hours to obtain Ta 3 N 5 Powder; Ta 3 N 5 Immerse the powder in 5mL of aqua regia, and place it in a 353-363K oven for heat treatment for 2...

Embodiment 2

[0035] Preparation and Performance Test of TaON Nanoparticles

[0036]Under the condition of temperature at 298K, tantalum pentachloride ethanol solution (1g tantalum pentachloride, 5mL ethanol) was dissolved in 100mL deionized water to obtain transparent solution S1; 20g of sodium hydroxide was dissolved in 100mL deionized water, Obtain a transparent solution S2; add the S2 solution dropwise to the stirred S1 solution at a rate of 30 drops per minute, from the beginning to the end of the stirring, the whole process takes 3 hours, and the product is a flocculent white oxide, Wash with deionized water until the pH value is neutral, and place it in an oven to obtain the metal oxide precursor powder P1; the powder P1 is placed in an alumina crucible, and under the protection of an ammonia atmosphere, it is burned at 1073K for 2 hours to obtain TaON powder; impregnate TaON powder in 5mL of aqua regia, and place it in a 353-363K oven for heat treatment for 2-12 hours; absorb the up...

Embodiment 3

[0039] LaTaON 2 Preparation and performance testing of nanoparticles

[0040] Under the condition of temperature at 298K, dissolve 1.2095g lanthanum nitrate hexahydrate and tantalum pentachloride ethanol solution (1g tantalum pentachloride, 5mL ethanol) in 100mL deionized water to obtain transparent solution S1; Dissolve in 100mL deionized water to obtain a transparent solution S2; add the S2 solution dropwise to the stirred S1 solution at a rate of 50 drops per minute, from the beginning of the dropwise addition to the end of the stirring, the entire process time is 6 hours, the product It is a flocculent white oxide, washed with deionized water until the pH value is neutral, and placed in an oven to obtain a metal oxide precursor powder P1; the powder P1 is placed in an alumina crucible, and under the protection of an ammonia atmosphere, it is burned at 1223K Burn for 10 hours and get LaTaON 2 Powder; LaTaON 2 Immerse the powder in 5mL of aqua regia, and place it in a 353...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com