Monodispersed spherical titanium dioxide core-shell structure composite material and preparation method thereof

A titanium dioxide, core-shell structure technology, applied in the field of monodisperse spherical titanium dioxide core-shell structure composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the monodisperse spherical titanium dioxide core-shell structure composite material co-modified by a novel non-metal and noble metal, comprising the following steps:

[0048] 1) Weighing 0.5-2 g of carbohydrate compounds and dissolving them in water to prepare an aqueous solution of carbohydrate compounds with a concentration of 0.1-5 mol / L and placing them in a hydrothermal reaction kettle. React at a temperature of 150-200°C for 10-20 hours (preferably 160-200°C closed reaction for 15-20 hours). After the reaction, centrifuge, wash, and dry at 60-100°C to obtain carbon spheres. Wherein the sugar compound concentration is preferably 0.8-3mol / L, the temperature is preferably 160-190°C, and the reaction time is preferably 16-18 hours;

[0049] 2) Prepare a certain amount of carbon spheres obtained into a 0.02-0.1 mol / L ethanol solution, and drop a certain amount (0.1-30 ml) of water into the solution. Add a cer...

Embodiment 1

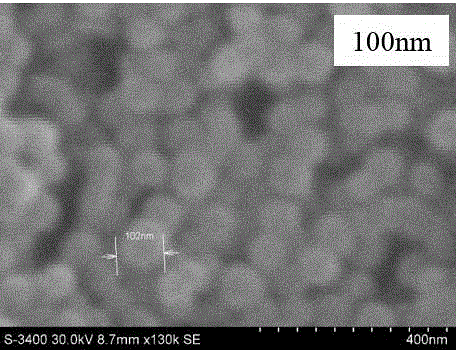

[0065] 1) Weigh 0.5g of glucose and dissolve it in water to form a solution of 0.05 mol / L, and react in a closed manner at 200°C for 15 hours to obtain uniform monodisperse carbon spheres with a diameter of 1000nm;

[0066] 2) Dissolve a certain amount of the obtained carbon spheres in ethanol to form a 0.1 mol / liter solution, and add 3ml of deionized water. Take 0.5ml of tetrabutyl titanate and add it to the solution twice, and react at a certain temperature of 45°C for a period of time;

[0067] 3) Add 5ml of 2% hydrazine to the solution obtained in step 2), stir for 30min, add 0.5ml of 0.03mol / liter AgCl solution, and illuminate with a xenon lamp for 10-30min;

[0068] 4) Centrifuge the solution obtained in step 3), wash with ethanol, and then centrifuge again, repeating this several times;

[0069] 5) Dry the powder obtained in step 3) in an oven at temperatures of 100° C. and 500° C. (vacuum) for several hours to obtain a carbon-silver composite modified titanium dioxide...

Embodiment 2

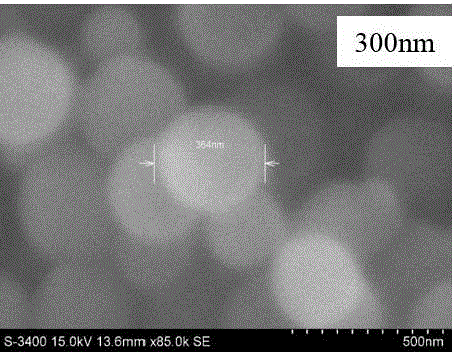

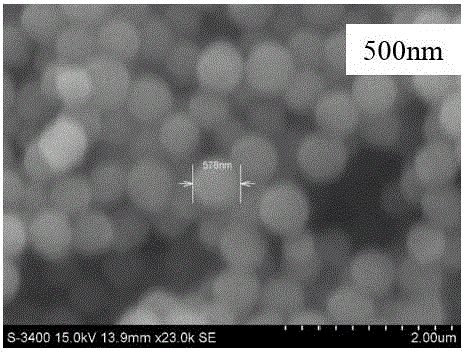

[0078] 1) Weigh 0.5g of glucose and dissolve it in water to form a solution of 0.05 mol / L, and react in a closed manner at 180°C for 15 hours to obtain uniform monodisperse carbon spheres with a diameter of 500nm;

[0079]2) Dissolve a certain amount of the obtained carbon spheres in ethanol to form a 0.1 mol / liter solution, and add 3ml of deionized water. Take 0.5ml of tetrabutyl titanate and add it to the solution twice, and react at a certain temperature of 45°C for a period of time;

[0080] 3) Add 5ml of 2% hydrazine to the solution obtained in step 2), stir for 30min, add 0.5ml of 0.03mol / liter AgCl solution, and illuminate with a xenon lamp for 10-30min;

[0081] 4) Centrifuge the solution obtained in step 3), wash with ethanol, and then centrifuge again, repeating this several times;

[0082] 5) Dry the powder obtained in step 3) in an oven at temperatures of 100° C. and 500° C. (vacuum) for several hours to obtain a carbon-silver compound-modified titanium dioxide co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com