Preparation method of microwave radiation enhancement alkali-modified carbon-supported noble metal catalyst for production of cinnamyl alcohol by means of selective hydrogenation

A noble metal catalyst and microwave radiation technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, and organic compound preparation, can solve the problem of no microwave-enhanced alkali-modified activated carbon, etc., and achieve easy The effect of control, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

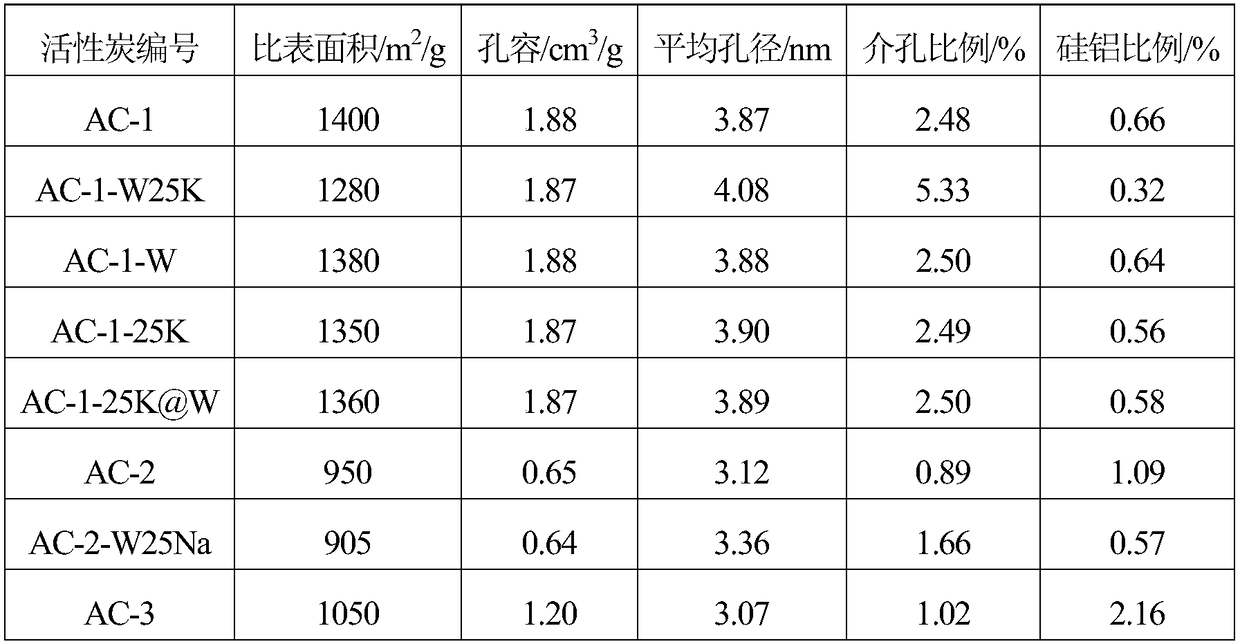

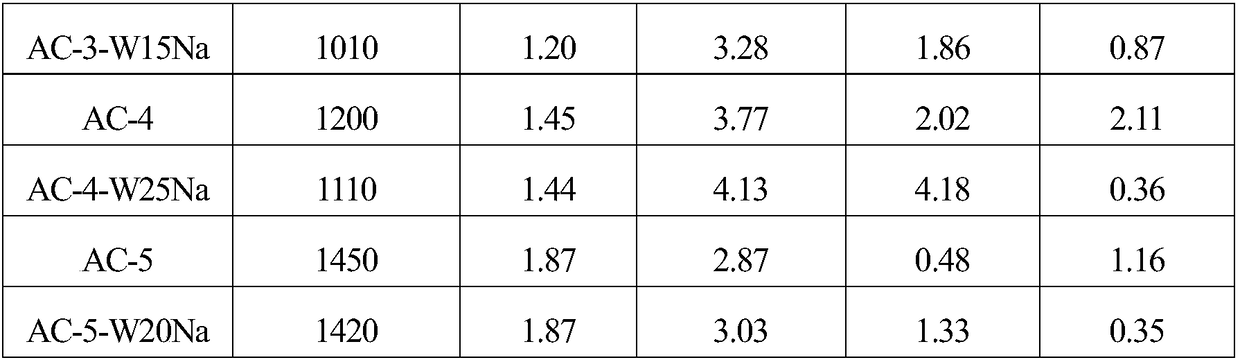

Embodiment 1

[0021] Weigh 20.0g of wood activated carbon powder (referred to as AC-1), uniformly stir and disperse it into 200mL KOH aqueous solution with a mass fraction of 25% at a temperature of 90°C, and under the action of microwave radiation with a power of 1.5kW, the original Modified activated carbon for 90min. After the modification is finished, the reaction solution is filtered, the modified activated carbon is washed with deionized water until the pH of the filtrate is neutral, and the filter cake is transferred to a blast drying oven at 110° C. for drying to obtain the modified activated carbon (note for AC-1-W25K).

[0022] Using the impregnation method, add the AC-1-W25K prepared above into distilled water to make a slurry, then add 10g / L aqueous solution of chloroplatinic acid to the slurry according to the platinum loading of 1wt%, keep stirring, and during the stirring process Adjust the pH of the solution to 10.0 with potassium hydroxide aqueous solution, then continue t...

Embodiment 2

[0024] Weigh 20.0g of wood activated carbon powder (referred to as AC-2), uniformly stir and disperse it into 400mL NaOH aqueous solution with a mass fraction of 25% at a temperature of 55°C, and under the action of microwave radiation with a power of 1.5kW, the original Modified activated carbon for 60min. After the modification is finished, the reaction solution is filtered, the modified activated carbon is washed with deionized water until the pH of the filtrate is neutral, and the filter cake is transferred to a blast drying oven at 110° C. for drying to obtain the modified activated carbon (note is AC-2-W25Na).

[0025] Using the impregnation method, add the AC-2-W25Na prepared above into distilled water to make a slurry, and then add 10 g / L of chloroplatinic acid aqueous solution to the slurry according to a platinum loading of 1 wt%, keep stirring, and in the stirring process Adjust the pH of the solution to 10.0 with potassium hydroxide aqueous solution, then continue...

Embodiment 3

[0027] Take by weighing 20.0g apricot shell activated carbon powder (referred to as AC-3), it is uniformly stirred and dispersed into 200mL temperature is that the mass fraction of 75 ℃ is in the NaOH aqueous solution of 15%, and under the microwave radiation effect that power is 1.5kW, Activated carbon was modified in situ for 90 min. After the modification is finished, the reaction solution is filtered, the modified activated carbon is washed with deionized water until the pH of the filtrate is neutral, and the filter cake is transferred to a blast drying oven at 110° C. for drying to obtain the modified activated carbon (note is AC-3-W15Na).

[0028] Using the impregnation method, add the AC-3-W15Na prepared above into distilled water to make a slurry, and then add 10 g / L of chloroplatinic acid aqueous solution to the slurry according to the platinum loading of 1 wt%, keep stirring, and in the stirring process Adjust the pH of the solution to 10.0 with potassium hydroxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com