Carbonized plant leaf @ZnO/Au heterojunction multistage structure assembly catalyst and preparation method thereof

A technology for carbonizing plants and plant leaves, applied in the field of photocatalysis, can solve the problems of poor dispersion of nano-powder catalytic materials, high photo-generated electron-hole recombination rate, limited sunlight utilization, etc., and achieves good photocatalytic degradation performance, The effect of improving light energy harvesting ability and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Fresh spinach leaves (35.2 mg) were cleaned with deionized water and frozen at -20°C for 24 hours, then vacuum freeze-dried at -50°C for 48 hours, and then the freeze-dried leaves were placed in a tube furnace Calcined at a high temperature of 1000° C. for 1 hour to obtain carbonized spinach leaves (4.3 mg).

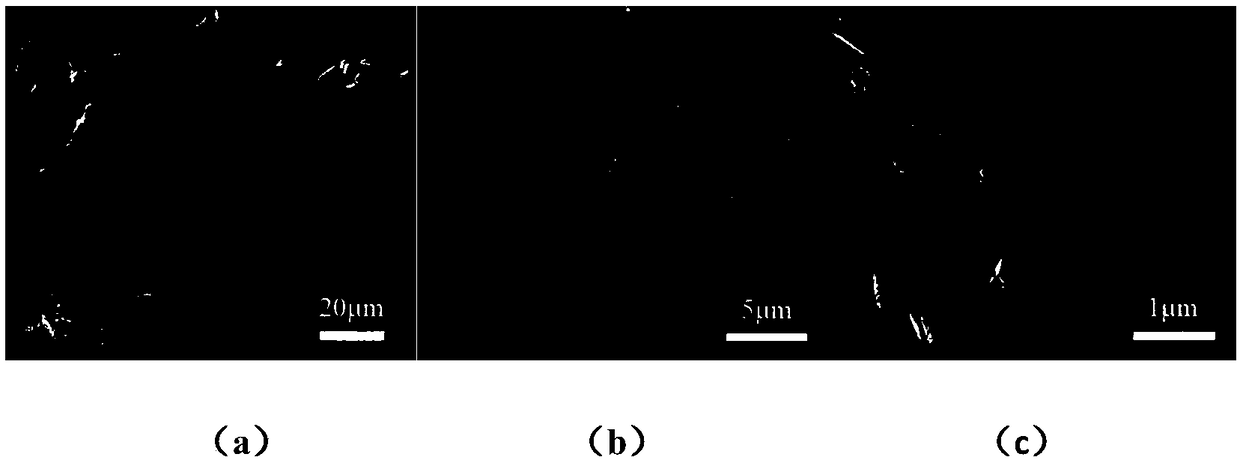

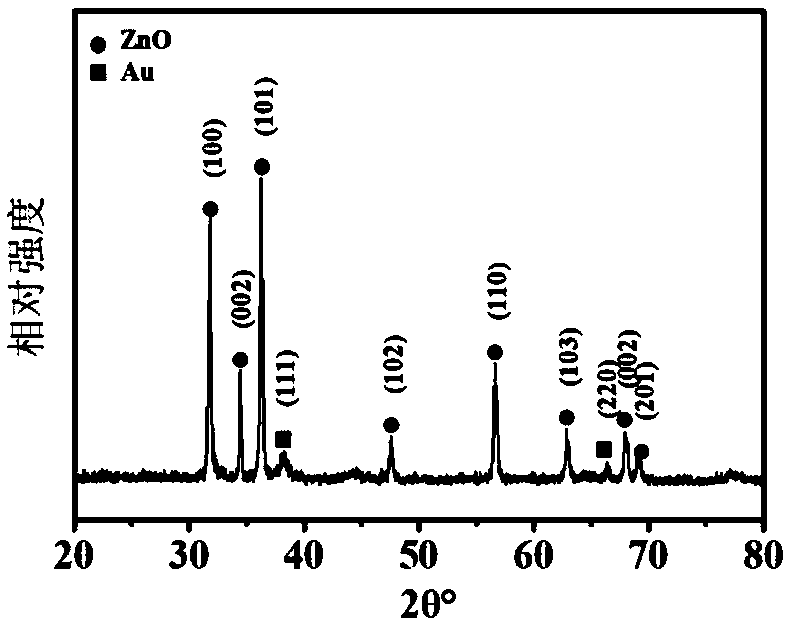

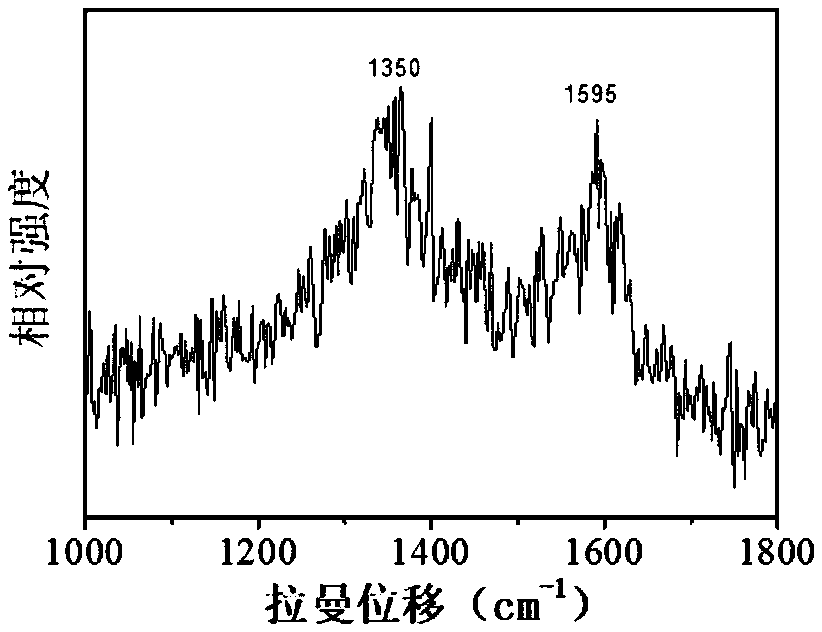

[0020] 2) Add 22mg of zinc acetate into 10mL of anhydrous methanol, heat and stir at 60°C to fully dissolve, then add 10mL of 0.03M methanol solution of sodium hydroxide dropwise; continue heating and stirring at 60°C for 2 hours to obtain a spherical ZnO nanocrystal seed solution; After the nanocrystal seed solution is naturally cooled to room temperature, the carbonized spinach blade obtained in step 1) is immersed in the above-mentioned ZnO nanocrystal seed solution and taken out after 10 seconds, so that the seeds evenly cover the blade surface, and then placed Heat in an oven at 90°C for 20 minutes to fix the ZnO seeds on the surface of the leaves; then pr...

Embodiment 2

[0028] 1) Fresh spinach leaves (40.8mg) were frozen at -20°C for 24 hours, then vacuum freeze-dried at -50°C for 48 hours, and the freeze-dried leaves were calcined at 750°C in a tube furnace for 2 hours Carbonized spinach leaves (4.9 mg) were obtained.

[0029] 2) Add 22mg of zinc acetate into 10mL of anhydrous methanol, heat and stir at 60°C to fully dissolve, then add 10mL, 0.03M methanolic sodium hydroxide solution dropwise; continue heating and stirring at 60°C for 2 hours to obtain a spherical ZnO nanocrystal seed solution; After the nanocrystal seed solution is naturally cooled to room temperature, the carbonized spinach blade obtained in step 1) is immersed in the above-mentioned ZnO nanocrystal seed solution and taken out after 10 seconds, so that the seeds evenly cover the blade surface, and then placed Heat in an oven at 90°C for 20 minutes to fix the ZnO seeds on the surface of the leaves; then prepare an aqueous alkali solution of zinc salt, wherein the zinc salt ...

Embodiment 3

[0032] 1) Fresh spinach leaves (31.7mg) were frozen at -20°C for 24 hours, then vacuum freeze-dried at -50°C for 48 hours, and the freeze-dried leaves were calcined at 1000°C in a tube furnace for 1 hour Carbonized spinach leaves (3.8 mg) were obtained.

[0033] 2) Add 20 mg of zinc acetate into 10 mL of anhydrous methanol, heat and stir at 60 ° C to fully dissolve, then add 10 mL of 0.03 M sodium hydroxide methanol solution dropwise; continue heating and stirring at 60 ° C for 2 hours to obtain a spherical ZnO nanocrystal seed solution; After the nanocrystal seed solution is naturally cooled to room temperature, the carbonized spinach blade obtained in step 1) is immersed in the above-mentioned ZnO nanocrystal seed solution and taken out after 10 seconds, so that the seeds evenly cover the blade surface, and then placed Heat in an oven at 90°C for 20 minutes to fix the ZnO seeds on the surface of the leaves; then prepare an aqueous alkali solution of zinc salt, wherein the zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com