Preparation method of Fe-Au alloy nanoparticles with bcc structures

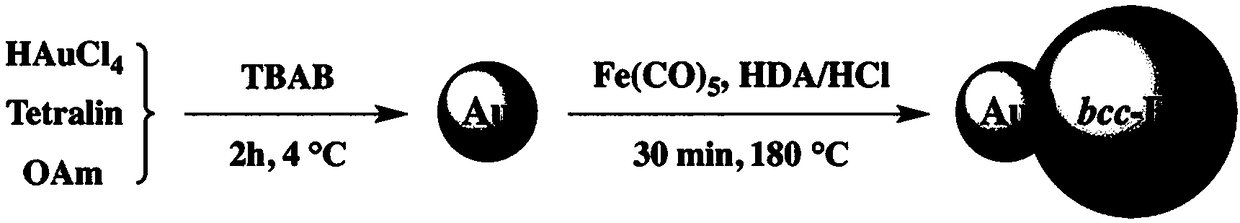

A technology of alloy nanoparticles and gold nanoparticles, which is applied in the field of preparation of Fe-Au alloy nanoparticles, achieves the effects of uniform shape and size, simple preparation process and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

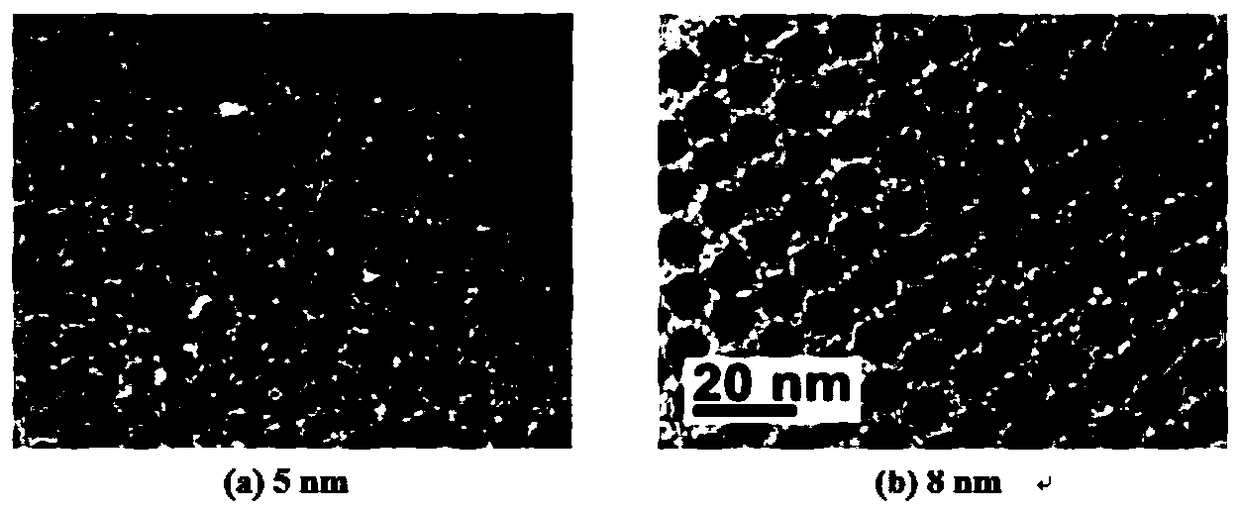

[0028] Example 1 Preparation of Au nanoparticles with a particle size of 5nm

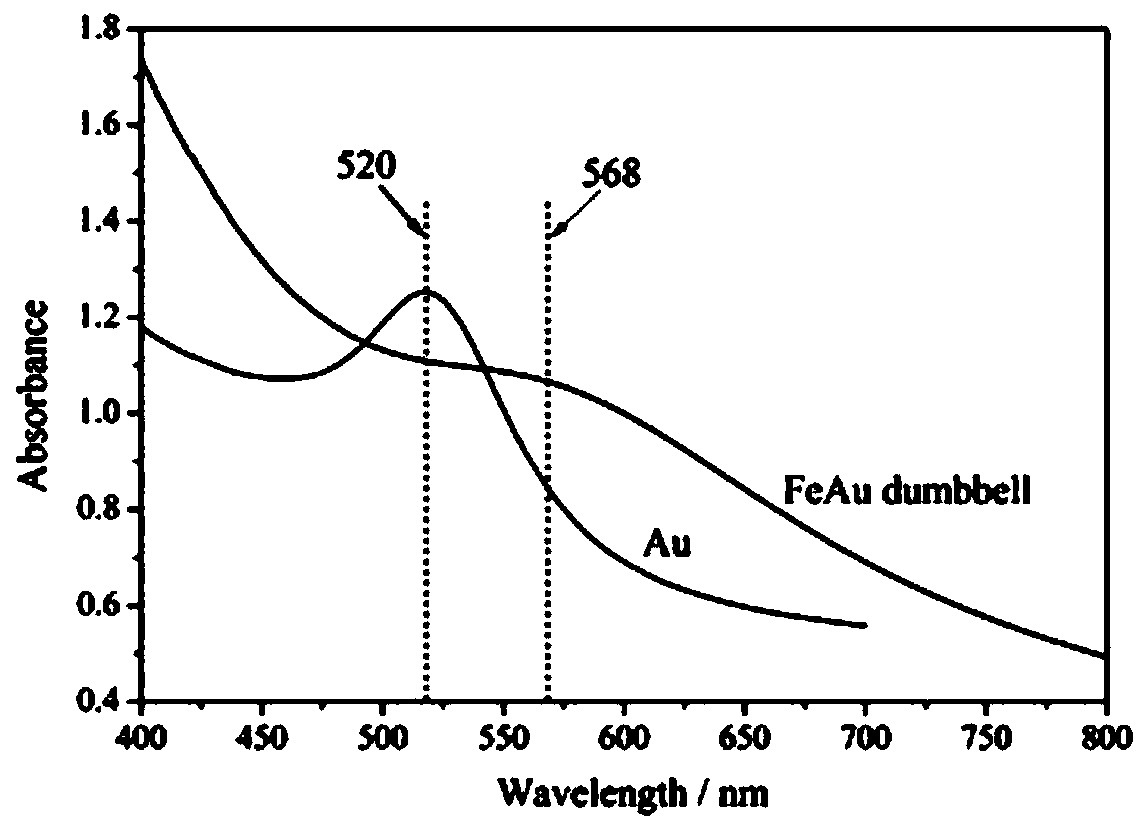

[0029] Such as figure 1 Shown in (a) is that particle diameter is the transmission electron microscope figure (TEM) of the Au nanoparticle of 5nm, and its preparation method is: under 4 ℃ of argon protections, 0.2g chloroauric acid is dissolved in 10ml tetrahydronaphthalene and In 10ml of oleylamine, magnetic stirring was used to dissolve it completely, and the stirring rate was 600rpm / min to obtain a golden yellow solution A. 90 mg of borane-tert-butylamine complex TBAB was dissolved in 1 ml of tetralin and 1 ml of oleylamine under ultrasonication to obtain a transparent solution B. Slowly inject solution B into solution A under magnetic stirring to obtain mixed solution C. After the mixed solution C was stirred at 4°C for 2 hours, a maroon solution D was obtained. Add 40ml of acetone to solution D, centrifuge at a high speed of 10000rpm for 8 minutes and discard the solvent. The obtained produc...

Embodiment 2

[0030] Example 2 Preparation of Au nanoparticles with a particle size of 8nm

[0031] Such as figure 1 Shown in (b) is the transmission electron microscope figure (TEM) of the Au nanoparticle with a particle diameter of 8nm, and its preparation method is: under the protection of argon gas at room temperature, the 5nm Au nanoparticle prepared by the above-mentioned embodiment 1 of 30mg Dissolve in 10ml 1-octadecene, 10ml oleylamine and 0.1g chloroauric acid mixed solution under magnetic stirring. Then, the temperature of the system was raised to 80° C. at 5° C. / min, and cooled to room temperature after reacting for 2 hours. Add 40ml of isopropanol to the solution, centrifuge at a high speed of 10000rpm for 8 minutes and discard the solvent. The obtained product is dispersed in 20ml of n-hexane, washed twice with 40ml of ethanol and dried to obtain 8nm gold nanoparticles.

Embodiment 3

[0032] Embodiment 3 preparation cetylamine hydrochloride

[0033] Preparation of cetylamine hydrochloride comprises the following steps: (1) preparing 12ml, 1M diethyl ether solution A of hydrochloride;

[0034] (2) 10mmol of hexadecylamine was dissolved in 100ml of n-hexane to obtain solution B;

[0035](3) Slowly drop solution A into solution B under ice bath and magnetic stirring conditions. After producing a large amount of white precipitates, the system was warmed up to room temperature and continued to stir for 2 hours;

[0036] (4) Remove the solvent of the system, wash the precipitate three times with n-hexane, and obtain cetylamine hydrochloride after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com