Method for forming porous bone hydroxyapatite ceramic cytoskeleton based on photo-curing 3D printing technology

A bone hydroxyapatite and 3D printing technology, which is applied to ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of inability to produce cell scaffold structures and complex structure hydroxyapatite samples, and achieve High molding precision, good biocompatibility, and the effect of promoting proliferation and differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

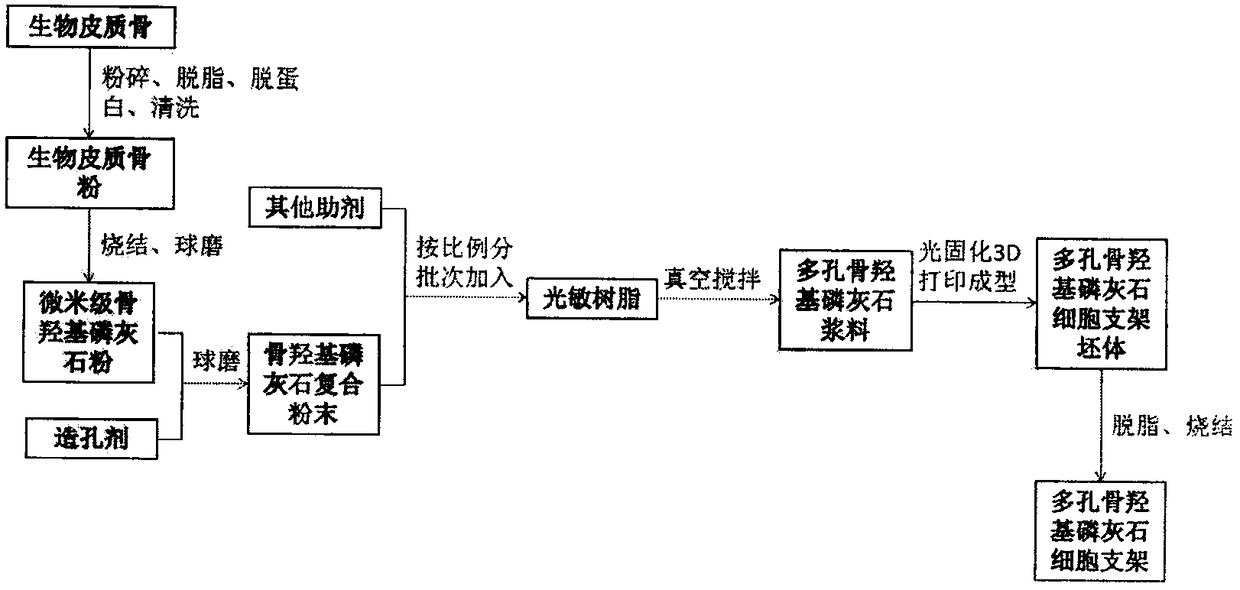

[0071] Embodiment 1, porous bovine bone hydroxyapatite cell scaffold

[0072] 1. The bovine cortical bone is pulverized with a pulverizer, dehydrated and degreased with ethanol, cleaned with ethanol ultrasonic wave, and dried. After calcining at 700°C for 2 hours, it was ground through a 100-mesh sieve.

[0073] 2. Put bovine cortical bone powder into a planetary ball mill, use zirconia balls with a diameter of 3 to 5 mm, the ball to material ratio is 1:4, the ball milling speed is 250 to 300 r / min, and the ball mill is 12 to 14 hours to obtain an average particle size of less than 20 μm bovine bone hydroxyapatite powder.

[0074] 3. The ball-milled bovine bone hydroxyapatite powder and carbon powder are dispersed by ball milling in a mass ratio of 4:1.

[0075] 4. Add the bone hydroxyapatite composite powder and other additives into the photocurable resin three times, and stir at normal pressure for 5-10 minutes after each addition until the weight of the bovine bone hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com