Aliphatic water-based polyurethane dispersion and water-based dry adhesive for synthetic leather including it

A water-based polyurethane, aliphatic technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of difficult to uniformly bake out moisture, thick base, airtight and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

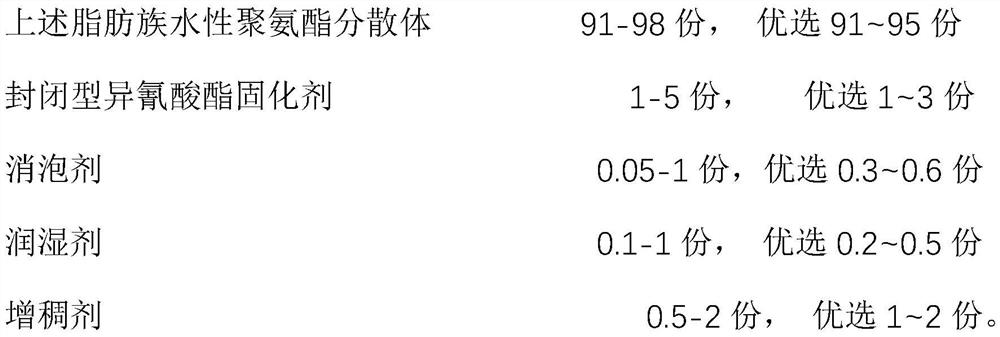

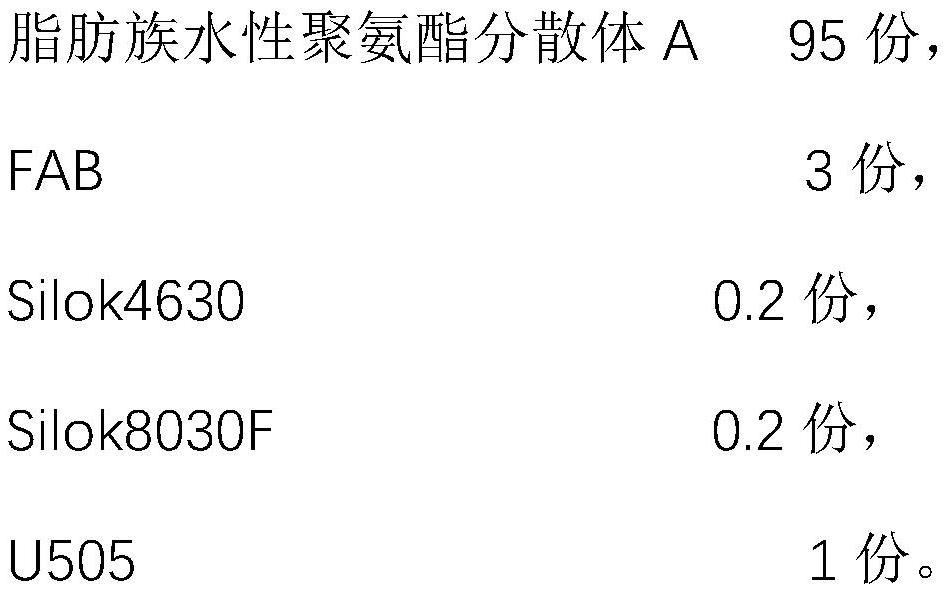

[0034] The synthetic leather water-based dry adhesive is prepared from the following raw materials in parts by weight (1 part by weight is 1 gram):

[0035]

[0036] In the present embodiment, the preparation method of the aliphatic aqueous polyurethane dispersion A is as follows: 200g of tetrahydrofuran-propylene glycol copolymerized glycol (number average molecular weight 2000), 15g of HMDI, 50g of acetone, 20g of dimethylolpropionic acid, 2g of Add diethylene glycol and 0.4g organic bismuth 2811 into a 1L four-neck round bottom flask equipped with a nitrogen inlet and outlet, and stir the mixture at 60-80°C for 3.5h (reaction) until the NCO% reaches 2%. Add 150g of acetone to dilute and cool down to 35°C, then add 15g of AMP95, 7.5g of N-(2-hydroxyethyl)ethylenediamine and 7.5g of ethylenediamine for chain extension reaction, then add 15.1g of triethylamine Neutralize for about 5 min, then add 400 g of water to high shear disperse the mixture for 15 min. After the aceto...

Embodiment 2

[0040] The synthetic leather water-based dry adhesive is prepared from the following raw materials in parts by weight (1 part by weight is 1 gram):

[0041]

[0042] In the present embodiment, the preparation method of aliphatic water-based polyurethane dispersion B is as follows: 200g polytetrahydrofuran diol (number average molecular weight 2000), 20gIPDI, 40g acetone, 30g dimethylolpropionic acid, 3g neopentyl Diol and 0.3 g of organic bismuth 2808 were added to a 1 L four-neck round bottom flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 60-80° C. for 4 h until the NCO% reached 2%. Add 100g of acetone to dilute and cool down to 35°C, then add 20g of AMP95, 25g of N-(2-hydroxyethyl)ethylenediamine and 5g of ethylenediamine for chain extension reaction, then add 30g of triethylamine for neutralization for about 5min , and then add 350 g of water to high shear disperse the mixture for 15 min. After the acetone was separated by distillation, ...

Embodiment 3

[0046] The synthetic leather water-based dry adhesive is prepared from the following raw materials in parts by weight (1 part by weight is 1 gram):

[0047]

[0048] In the present embodiment, the preparation method of the aliphatic aqueous polyurethane dispersion C is as follows: 100 g of dehydrated polypropylene glycol diol (number average molecular weight 1000), 10 g of HDI, 30 g of acetone, 10 g of dimethylol propionic acid, and 1 g of acetone Diethylene glycol and 0.4g organic bismuth 2010 were added into a 1L four-neck round-bottomed flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 60-80°C for 5h until the NCO% reached 2.3%. Add 80g of acetone to dilute and cool down to 35°C, then add 10g of AMP95, 10g of N-(2-hydroxyethyl)ethylenediamine and 5g of ethylenediamine for chain extension reaction, then add 10g of triethylamine for neutralization for about 5min , and then add 200 g of water to high shear disperse the mixture for 15 min. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com