Sound-insulating composite material for rail traffic as well as preparation method thereof

A composite material and rail transportation technology, applied in the field of rail transportation, can solve the problems of poor damping and vibration reduction performance, high smoke density and smoke toxicity, which cannot meet the requirements of rail transportation, and achieve excellent vibration reduction and sound insulation performance, easy to operate, The effect of sound insulation optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

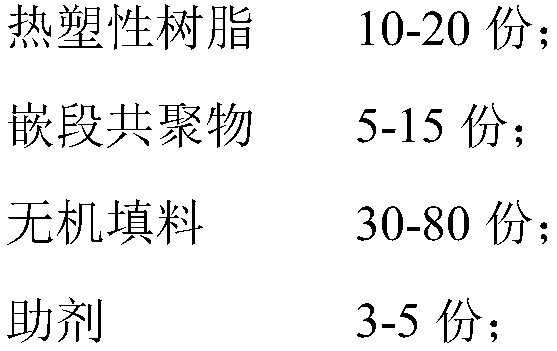

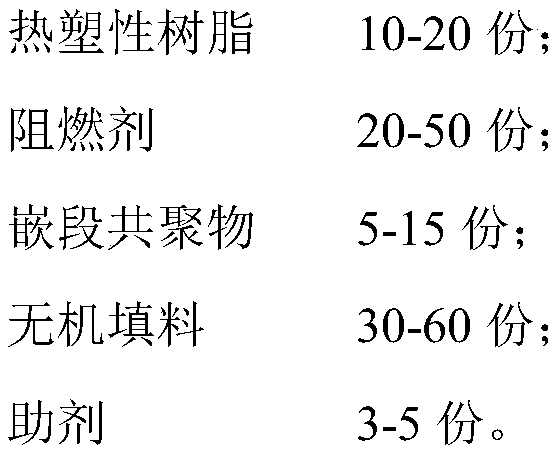

Method used

Image

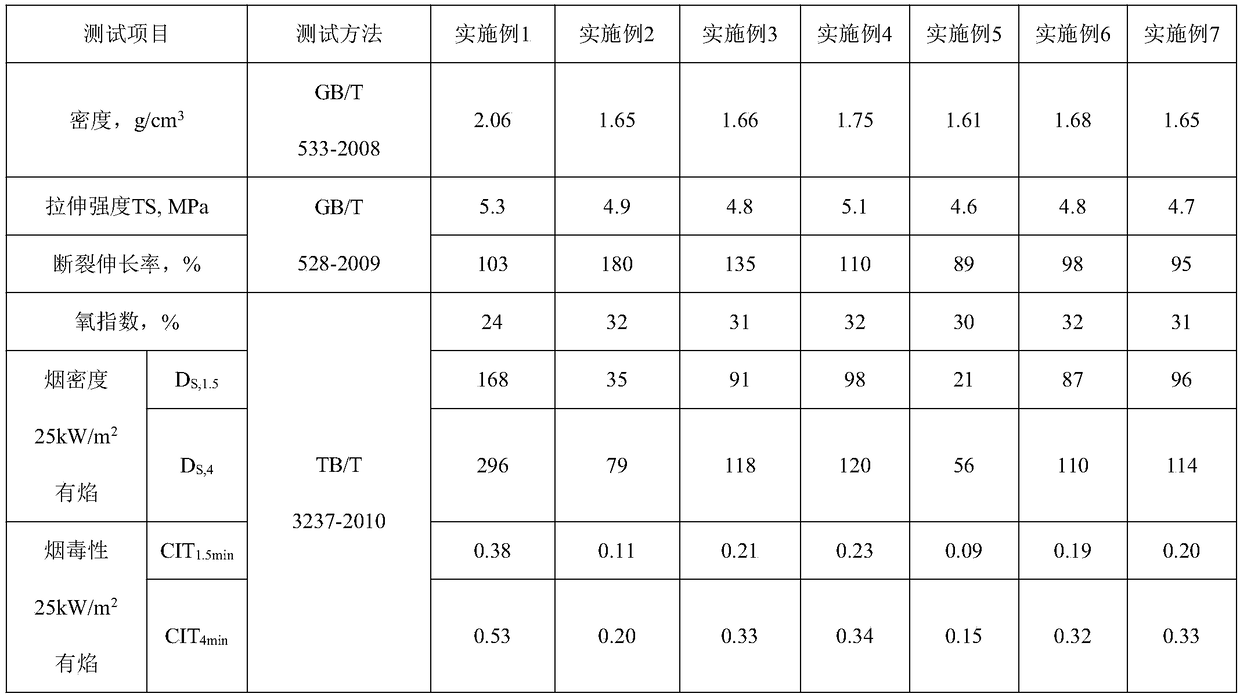

Examples

Embodiment 1

[0029] A sound-insulating composite material for rail transit, comprising the following components in parts by weight: 15 parts of ethylene-vinyl acetate copolymer, 10 parts of styrene-ethylene branched polydiene-styrene triblock copolymer, barium sulfate 75 parts, 2 parts of naphthenic oil, 1 part of stearic acid, 0.5 part of antioxidant, 0.5 part of coupling agent, and 1 part of dispersant. Wherein, the temperature of the peak of the loss factor tanδ of the styrene-ethylene branched polydiene-styrene triblock copolymer is 20° C., and the peak value is 1.2.

[0030] The preparation method of above-mentioned composite material comprises the following steps:

[0031] (1) Internal mixing: weigh each component according to the proportion and put it into an internal mixer preheated to 120-150°C, mix the materials and plasticize them evenly;

[0032] (2) Extrusion: Transport the plasticized material to the feed port of the extruder while it is hot and feed it through the conical t...

Embodiment 2

[0035] A sound-insulating composite material for rail transit, comprising the following components in parts by weight: 15 parts of ethylene-vinyl acetate copolymer, 10 parts of styrene-ethylene branched polydiene-styrene triblock copolymer, inorganic expansion 35 parts of flame retardant, 40 parts of barium sulfate, 2 parts of naphthenic oil, 1 part of stearic acid, 0.5 part of antioxidant, 0.5 part of coupling agent, and 1 part of dispersant. Among them, the temperature of the loss factor tanδ peak of styrene-ethylene branched polydiene-styrene triblock copolymer is 20°C, the peak value is 1.2, and the inorganic intumescent flame retardants are piperazine pyrophosphate and polymelamine phosphate according to The ratio relationship is a mixture of 2:1 combination.

[0036] The preparation method of the composite material in this embodiment is the same as that in Embodiment 1, and the thickness is 1mm.

Embodiment 3

[0038] A sound-insulating composite material for rail transit, comprising the following components in parts by weight: 15 parts of ethylene-vinyl acetate copolymer, 10 parts of styrene-ethylene branched polydiene-styrene triblock copolymer, inorganic expansion 35 parts of flame retardant, 40 parts of barium sulfate, 2 parts of naphthenic oil, 1 part of stearic acid, 0.5 part of antioxidant, 0.5 part of coupling agent, and 1 part of dispersant. Among them, the temperature of the loss factor tanδ peak of styrene-ethylene branched polydiene-styrene triblock copolymer is -5°C, the peak value is 0.7, and the inorganic intumescent flame retardants are piperazine pyrophosphate and polymelamine phosphate The mixture is combined 2:1.

[0039] The preparation method of the composite material in this embodiment is the same as that in Embodiment 1, and the thickness is 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com