Method for preparing Fe/Co/C composite wave-absorbing material on the basis of pyrolysis of modified MOF material

A composite wave-absorbing material and modification technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of less wave-absorbing composite materials and achieve excellent wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

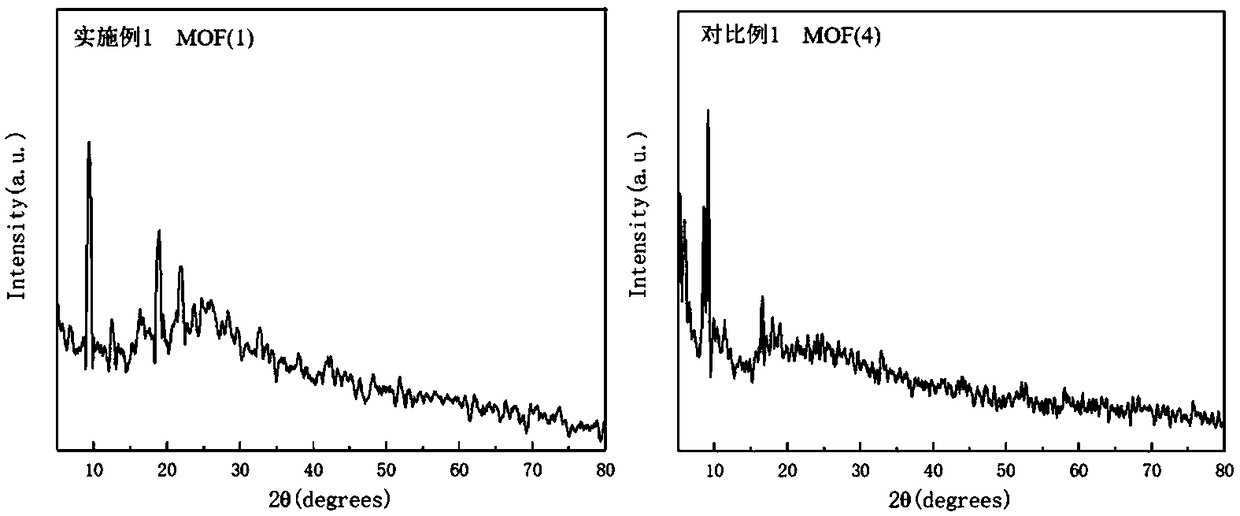

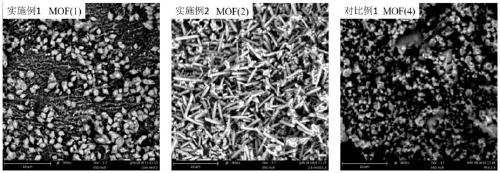

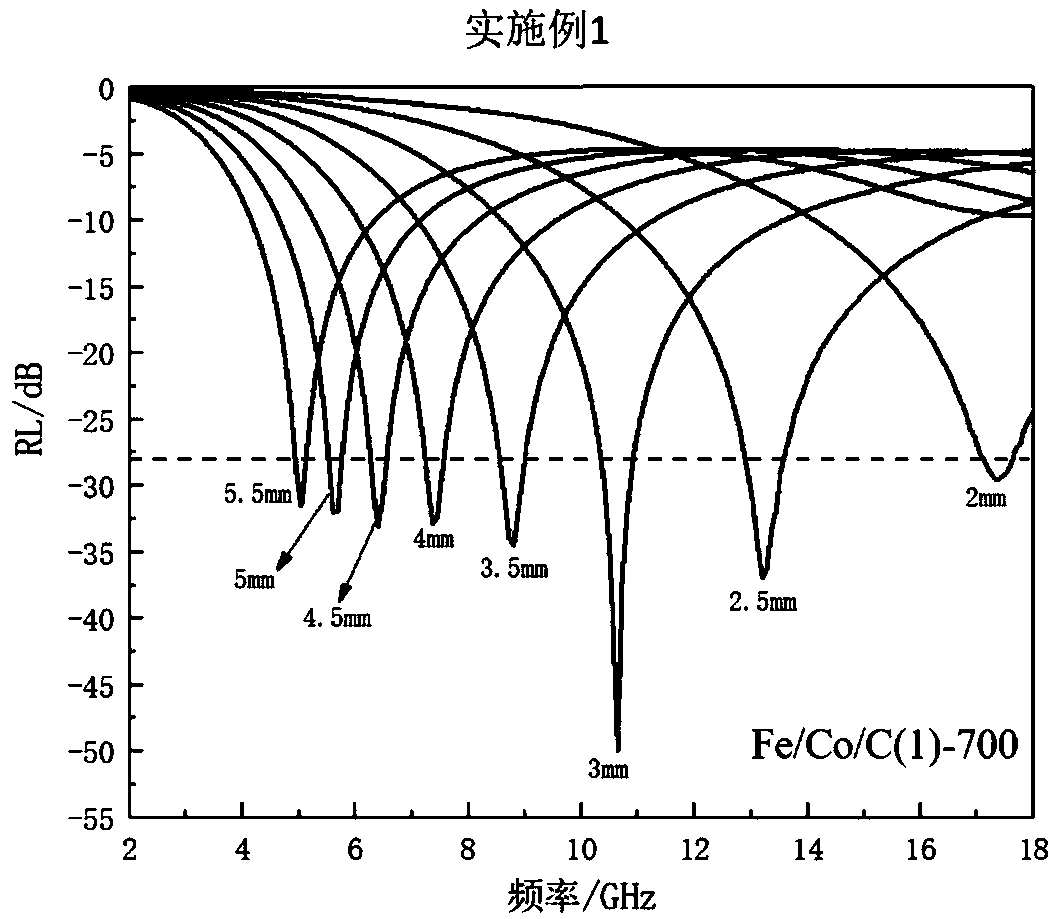

Embodiment 1

[0029] Step 1, weigh 0.675gFeCl 3 ·6H 2 O. 0.206g of terephthalic acid and 0.0821g of 2-methylimidazole were dissolved in 15mL of N,N-dimethylformamide solution, and dispersed by ultrasonic to obtain a homogeneous solution. Pipette this solution into a 100ml hydrothermal reaction kettle lined with Teflon, seal it and put it into an electric constant temperature blast drying oven to prepare the reaction in a temperature control mode. The hydrothermal temperature is controlled at 110°C. The time is controlled at 20h, and the reaction is naturally cooled after the end. Open the hydrothermal kettle at room temperature, remove the obtained orange-yellow turbid liquid and collect the orange-yellow solid by centrifugation in a high-speed centrifuge. After that, wash the solid twice with 60°C hot ethanol, and use a collector type constant temperature heating magnetic stirring for each washing The mixture was stirred for 3 hours, collected by centrifugation while it was hot, and drie...

Embodiment 2

[0033] This example is basically the same as Example 1, except that 0.2053 g of 2-methylimidazole is added in step 1.

[0034]The obtained MOF precursor is marked as MOF(2); the final product Fe / Co / C composite absorbing material is marked as Fe / Co / C(2)-700.

Embodiment 3

[0036] This embodiment is basically the same as embodiment 1, the only difference is that 0.3284g of 2-methylimidazole is added in step 1.

[0037] The obtained MOF precursor is marked as MOF(3); the final product Fe / Co / C composite absorbing material is marked as Fe / Co / C(3)-700.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com