High-temperature-resistant polyester lubricating oil base oil and preparation method thereof

A technology of lubricating oil base oil and high temperature resistant type, applied in the fields of lubricating oil base oil and its preparation, high temperature resistant polyester lubricating oil base oil and its preparation, can solve the problem of high temperature stability, low non-toxicity, high temperature resistance General, easy to degrade carbon deposits and other problems, to achieve the effect of good lubricating performance and wear resistance, moderate viscosity index, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

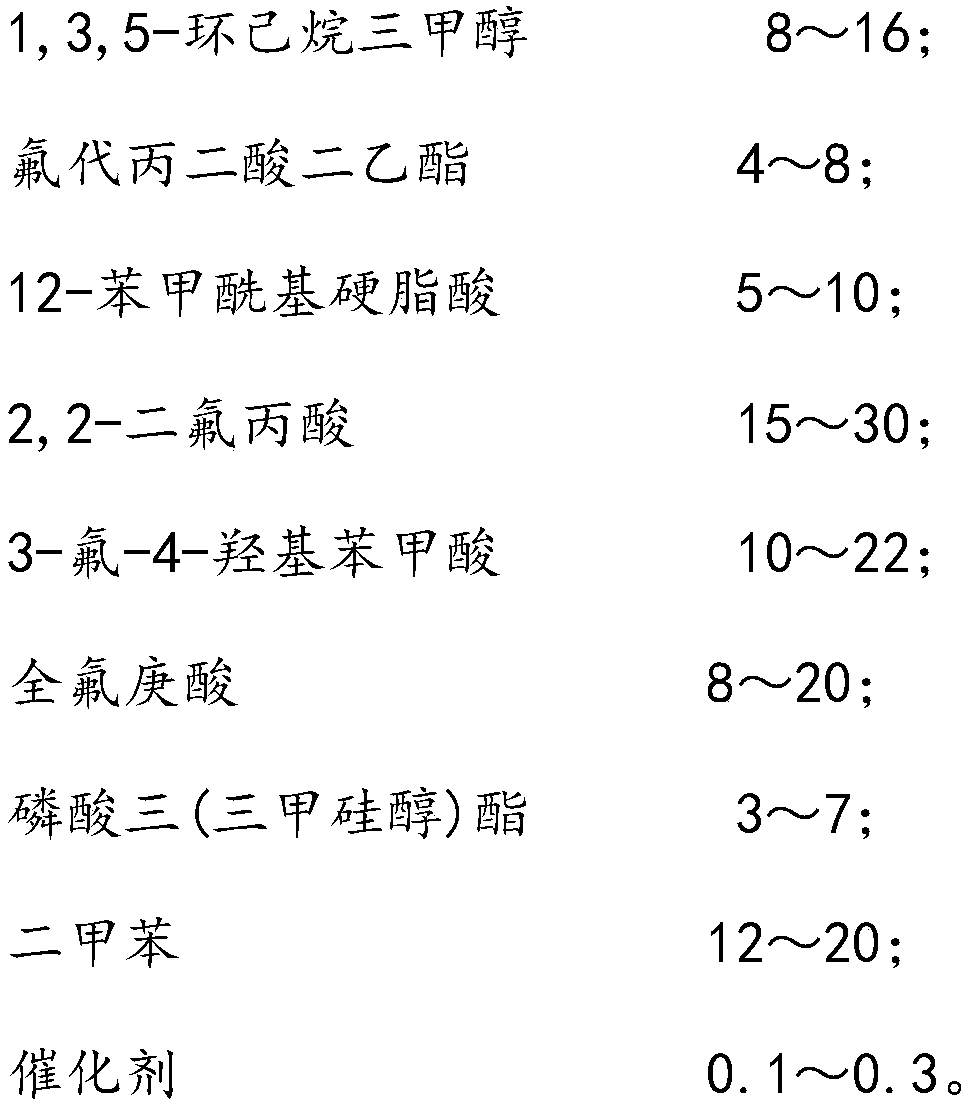

[0028] A kind of high temperature resistant type polyester lubricating oil base oil, is made by following raw material, and described parts are all molar percentages:

[0029]

[0030] A preparation method of high-temperature-resistant polyester lubricating oil base oil, comprising the following steps:

[0031] A. Add 1,3,5-cyclohexanetrimethanol, diethyl fluoromalonate, xylene, and catalyst into the reactor, start stirring and mix thoroughly, and heat up to 140-160°C for reflux and water separation reaction 2~4h;

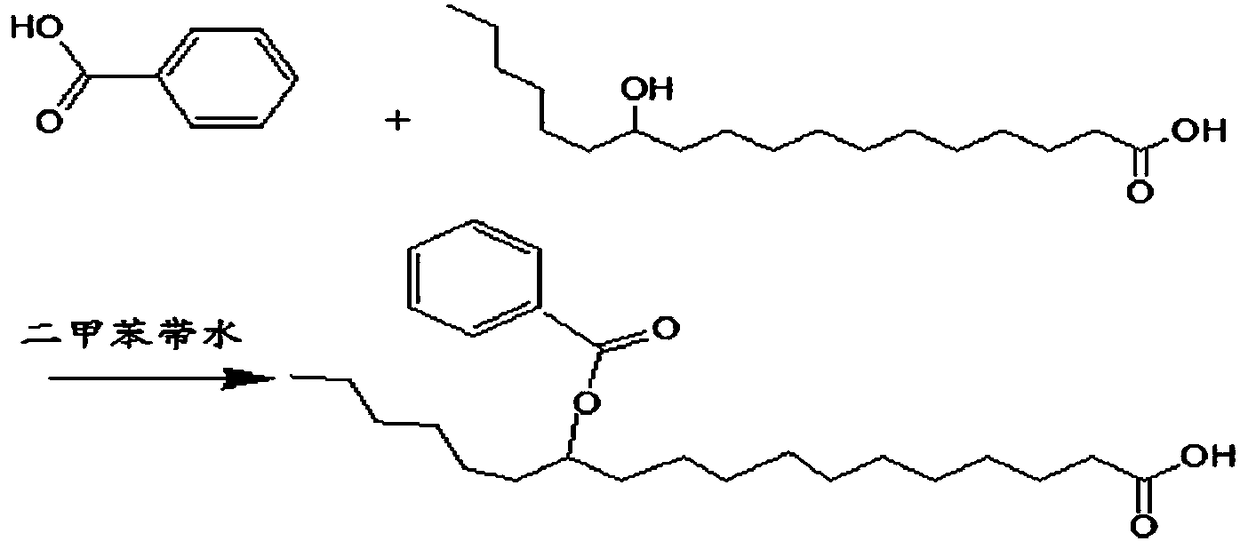

[0032] B. Add 12-benzoyl stearic acid, 2,2-difluoropropionic acid, and 3-fluoro-4-hydroxybenzoic acid into the reactor for full esterification reaction, and continue the water separation reaction at 150-160°C for 3 ~6h;

[0033] C. Then add perfluoroheptanoic acid and tris(trimethylsilyl) phosphate in the prescribed amount, heat up to 160-170°C for 2-4 hours, and stop the reaction when the acid value is less than 1mgKOH / g;

[0034] D. Add water to wash the ca...

Embodiment 2

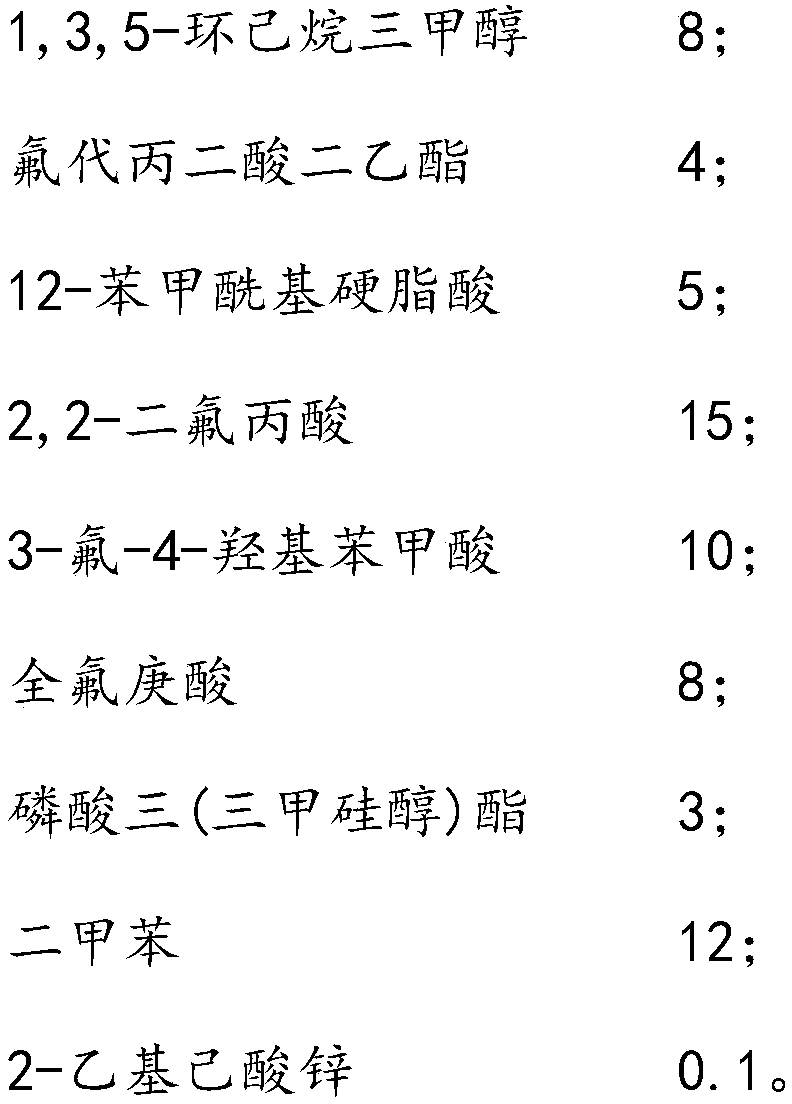

[0038] A kind of high temperature resistant type polyester lubricating oil base oil, is made by following raw material, and described parts are all molar percentages:

[0039]

[0040]

[0041] Its preparation method etc. are the same as embodiment 1.

Embodiment 3

[0043] A kind of high temperature resistant type polyester lubricating oil base oil, is made by following raw material, and described parts are all molar percentages:

[0044]

[0045] Its preparation method etc. are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com