Lubricant prepared from nano-material and preparation method thereof

A technology of nano-materials and lubricants, applied in the direction of mixing methods, lubricating compositions, mixed material pretreatment, etc., can solve the problem that lubricants do not have anti-oxidation and stability properties, extend the shelf life of base oil, and cannot reduce energy consumption, etc. problems, achieve good oxidation resistance and stability, good anti-wear extreme pressure, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

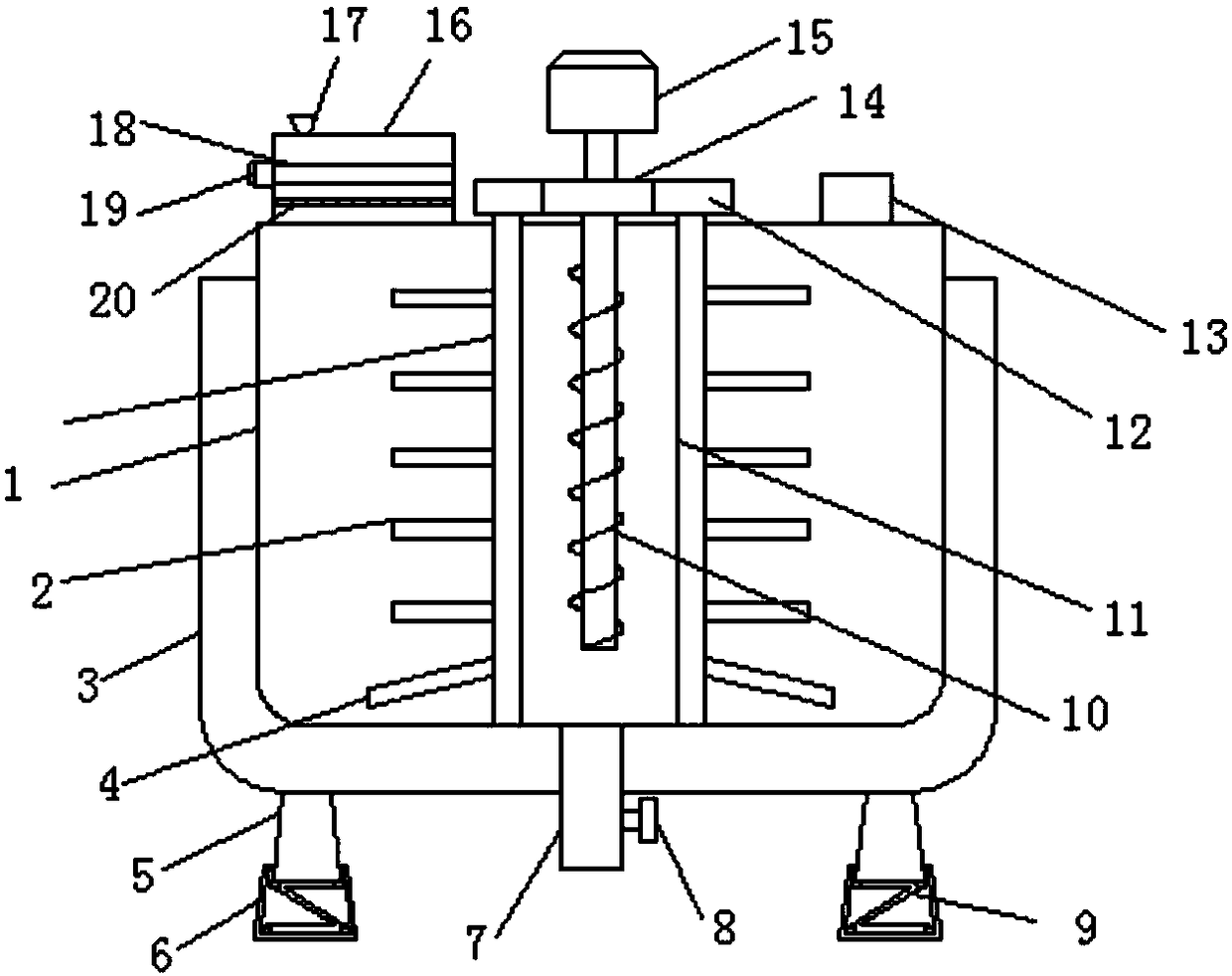

Method used

Image

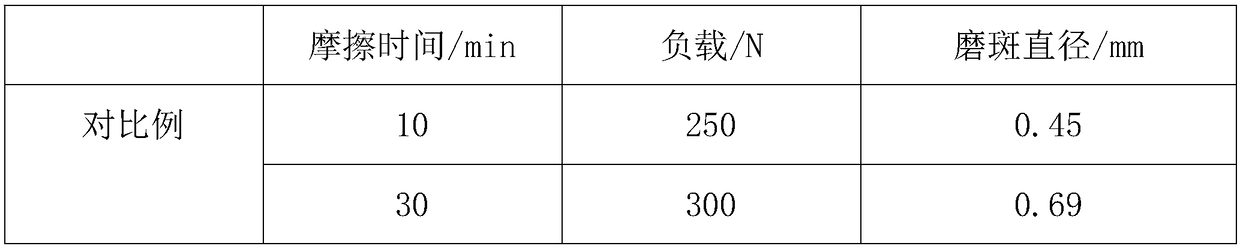

Examples

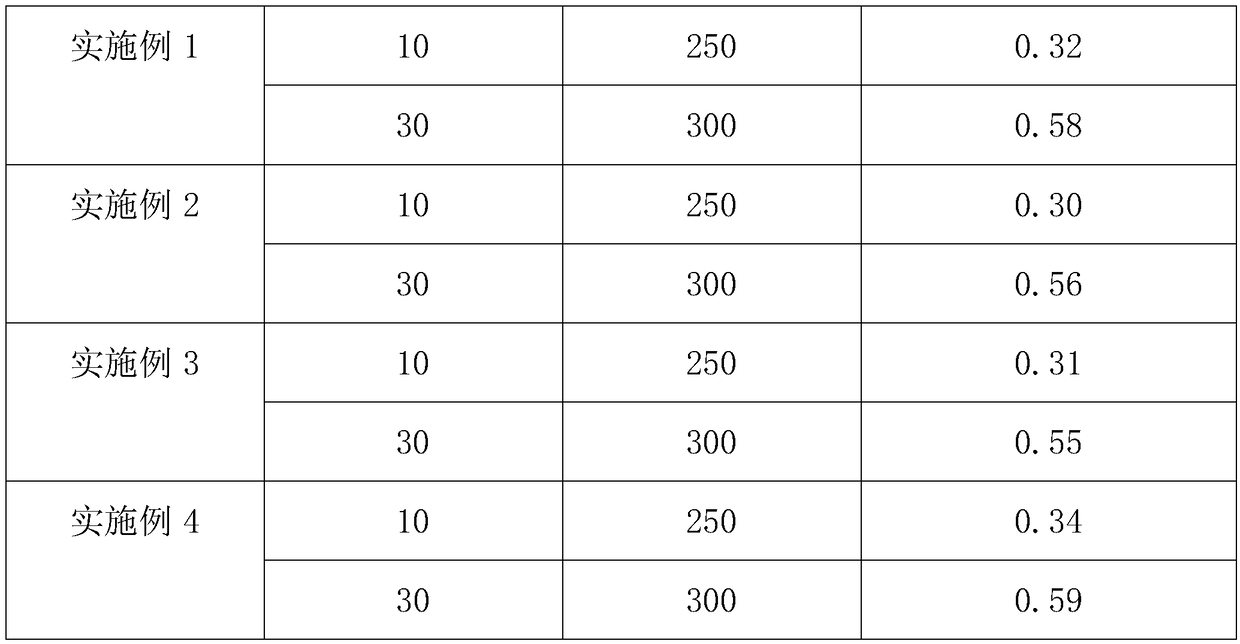

Embodiment 1

[0032] A lubricant prepared from nano-materials, the raw materials are 20 parts by weight of nano particles, 45 parts of base oil, 1 part of rust remover, 3 parts of modified antiwear extreme pressure agent and 2 parts of modified surface modifier;

[0033] Among them, the weight parts of the raw materials in the modified antiwear extreme pressure agent are 15 parts of diisotridecylamine, 17 parts of molybdenum oxide, 1 part of sodium benzoate, 3 parts of emulsified silicone oil and isopropyl-α-methylbenzene. 1 part of propionaldehyde;

[0034] The preparation method of the modified anti-wear extreme pressure agent includes the following steps:

[0035] 1) Add diisotridecylamine, molybdenum oxide and sodium benzoate to the reaction vessel in sequence, stir evenly for 2-3 hours, react to prepare a molybdenum amine complex precursor, wash the precursor with alcohol, and dry for 30 minutes; Add a certain amount of water solvent to the precursor and then stir for 1 hour, while slowly ad...

Embodiment 2

[0045] A lubricant prepared from nano-materials, the raw materials are 25 parts by weight of nano particles, 50 parts of base oil, 5 parts of rust remover, 8 parts of modified anti-wear extreme pressure agent and 7 parts of modified surface modifier;

[0046] Among them, the weight parts of the raw materials in the modified antiwear extreme pressure agent are 20 parts of diisotridecylamine, 20 parts of molybdenum oxide, 2 parts of sodium benzoate, 5 parts of emulsified silicone oil and isopropyl-α-methylbenzene. 5 parts of propionaldehyde;

[0047] The preparation method of the modified anti-wear extreme pressure agent includes the following steps:

[0048] 1) Add diisotridecylamine, molybdenum oxide and sodium benzoate to the reaction vessel in sequence, stir evenly for 2.5 hours, react to prepare a molybdenum amine complex precursor, wash the precursor with alcohol, and dry for 30 minutes; then drive forward Add a certain amount of water solvent to the body and then stir for 1.5 h...

Embodiment 3

[0058] A lubricant prepared from nanomaterials, the raw materials are 35 parts by weight of nano particles, 60 parts of base oil, 8 parts of rust remover, 15 parts of modified anti-wear extreme pressure agent, and 11 parts of modified surface modifier;

[0059] Among them, the weight parts of the raw materials in the modified antiwear extreme pressure agent are 30 parts of diisotridecylamine, 25 parts of molybdenum oxide, 3 parts of sodium benzoate, 11 parts of emulsified silicone oil and isopropyl-α-methylbenzene. 8 parts of propionaldehyde;

[0060] The preparation method of the modified anti-wear extreme pressure agent includes the following steps:

[0061] 1) Add diisotridecylamine, molybdenum oxide and sodium benzoate to the reaction vessel in sequence, stir evenly for 3 hours, and react to obtain a molybdenum amine complex precursor. Wash the precursor with alcohol and dry for 30 minutes; then drive forward Add a certain amount of water solvent to the body and stir for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com