Pre-deformation heat treatment technology for improving strength of metastable beta titanium alloy

A β-titanium alloy and pre-deformation technology, which is applied in the field of pre-deformation heat treatment technology, can solve the problems of insufficient pre-deformation deformation, failure to achieve strengthening effect, and failure to achieve strengthening effect, etc., to achieve convenient operation, increase strength, strength and good plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Use the present invention to TB8 metastable beta titanium alloy (its T β =810°C) for pre-deformation direct aging heat treatment process:

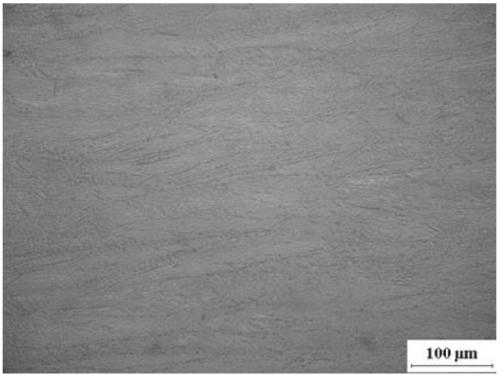

[0026] (1) The TB8 metastable β titanium alloy to be heat treated is pre-heated in the β-phase single-phase region, and the heat treatment system of the pre-heat treatment is 900 ° C for 4 hours and then quenched to room temperature; after the pre-heat treatment, the microstructure of the TB8 metastable β titanium alloy is single Phase β equiaxed crystal structure;

[0027] (2) The pre-heat-treated TB8 metastable β titanium alloy was held at 860 °C for 0.5 h, and then the TB8 titanium alloy was subjected to multi-pass rolling and thermal deformation by a rolling mill, with a total deformation of 20%, and then quenched to room temperature. After rolling, the deformation of the single-phase β phase is small, and it basically presents an equiaxed shape;

[0028] (3) Heat the hot-rolled and deformed TB8 titanium alloy to an aging temp...

Embodiment 2

[0031] Use the present invention to TB8 metastable beta titanium alloy (its T β =810°C) for pre-deformation direct aging heat treatment process:

[0032] (1) The TB8 metastable β-titanium alloy to be heat-treated is pre-heat-treated in the β-phase single-phase region, and the heat treatment system of the pre-heat treatment is 900°C for 4 hours and then quenched to room temperature;

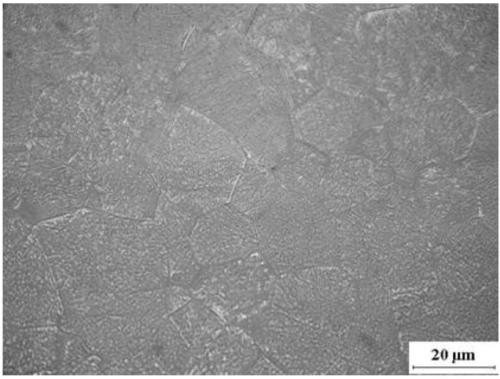

[0033] (2) heat-treated TB8 metastable β titanium alloy at 860°C for 0.5h, and then use a rolling mill to perform multi-pass rolling and thermal deformation of TB8 titanium alloy, with a total deformation of 40%, and then quench to room temperature;

[0034] (3) Heat the hot-rolled and deformed TB8 titanium alloy to an aging temperature of 540° C., keep it warm for 8 hours, and then air-cool it to room temperature.

[0035] In this example, the mechanical property parameters at room temperature of the TB8 metastable β titanium alloy after pre-deformation + direct aging heat treatment are shown in...

Embodiment 3

[0037] Use the present invention to TB8 metastable beta titanium alloy (its T β =810°C) for pre-deformation direct aging heat treatment process:

[0038] (1) The TB8 metastable β-titanium alloy to be heat-treated is pre-heat-treated in the β-phase single-phase region, and the heat treatment system of the pre-heat treatment is 900°C for 4 hours and then quenched to room temperature;

[0039] (2) heat-treated TB8 metastable β titanium alloy at 860°C for 0.5h, and then use a rolling mill to carry out multi-pass rolling and thermal deformation of TB8 titanium alloy, with a total deformation of 50%, and then quench to room temperature;

[0040] (3) Heat the hot-rolled and deformed TB8 titanium alloy to an aging temperature of 540° C., keep it warm for 8 hours, and then air-cool it to room temperature.

[0041] In this example, the mechanical property parameters at room temperature of the TB8 metastable β titanium alloy after pre-deformation + direct aging heat treatment are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com