A sulfur cathode composite material based on porous biomass carbon and a preparation method thereof

A biomass carbon and composite material technology, applied in the direction of active material electrodes, positive electrodes, battery electrodes, etc., can solve the problems of waste of biomass resources, backward preservation and conversion technology, etc., achieve high sulfur loading, expand the scope of application, The effect of improving specific capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Put the enucleated Panda Dahai in a high-pressure reactor, and conduct a hydrothermal reaction at 180°C for 12 h. The hydrothermal reaction product was filtered, dried, and ground; then, the ground powder was mixed with 5 M KOH ethanol solution and stirred for 18 h, wherein The mass ratio of the added powder to KOH was 1:3, and then the mixture was poured into a nickel crucible, dried at 80 °C, and calcined at 800 °C for 2 h under the protection of an argon atmosphere; finally, the calcined product was washed with 1 M dilute hydrochloric acid and Wash with deionized water until neutral and dry to obtain a porous biomass carbon material.

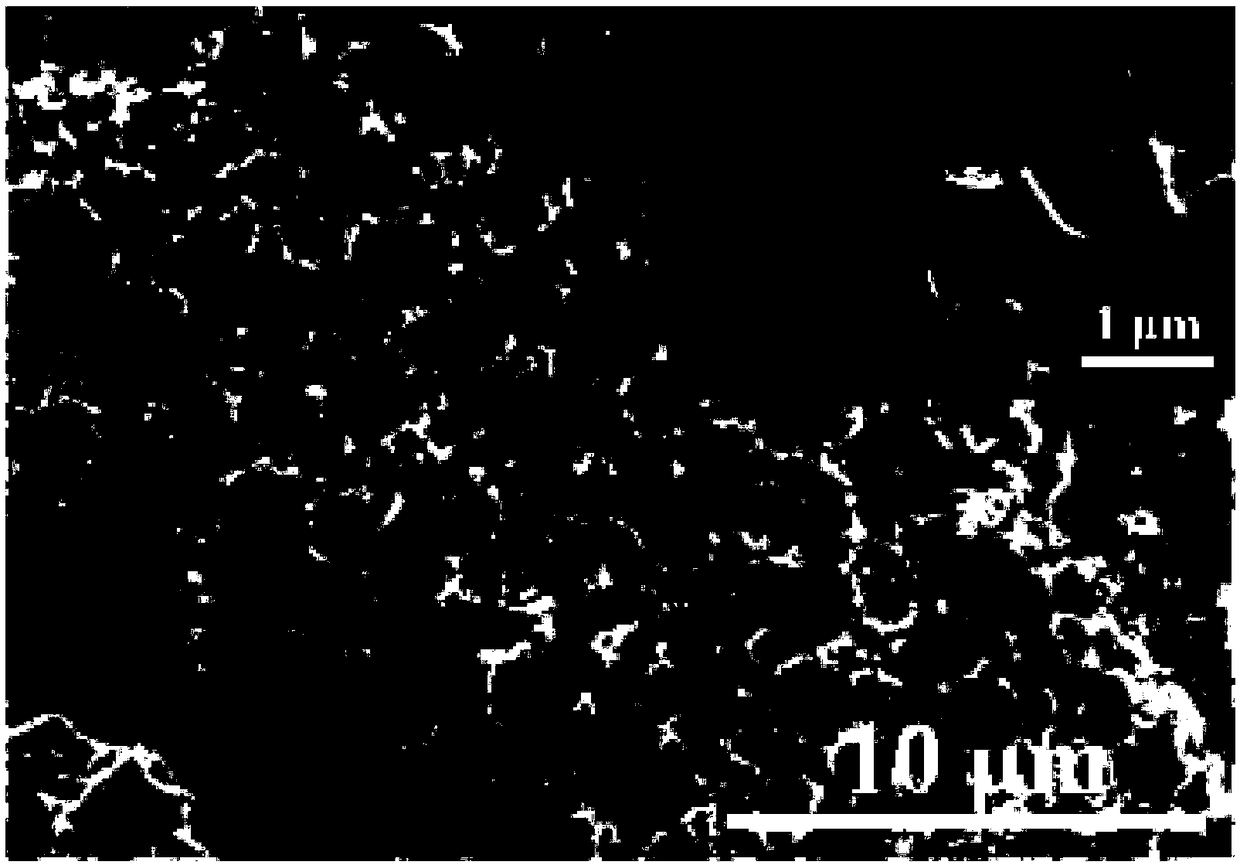

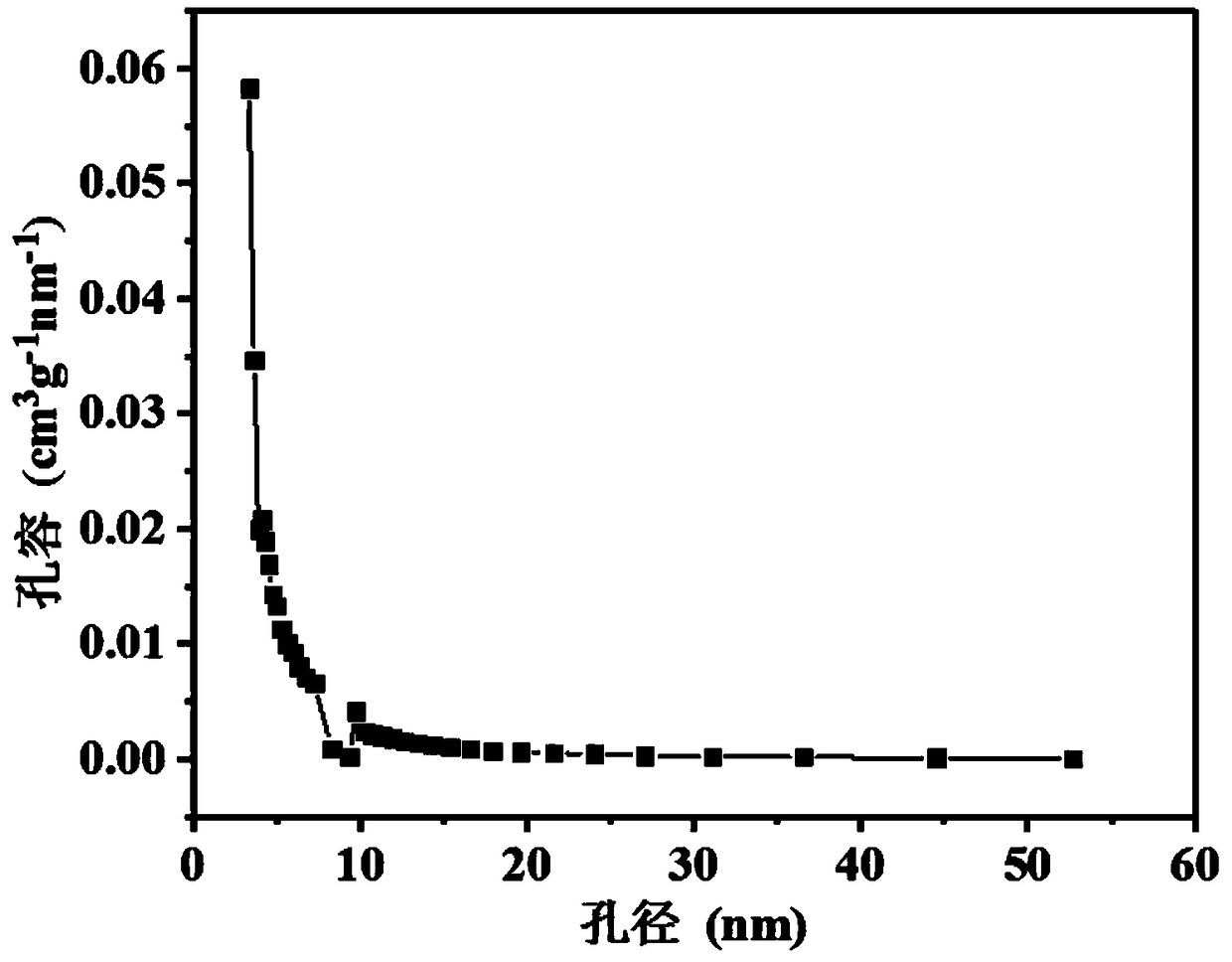

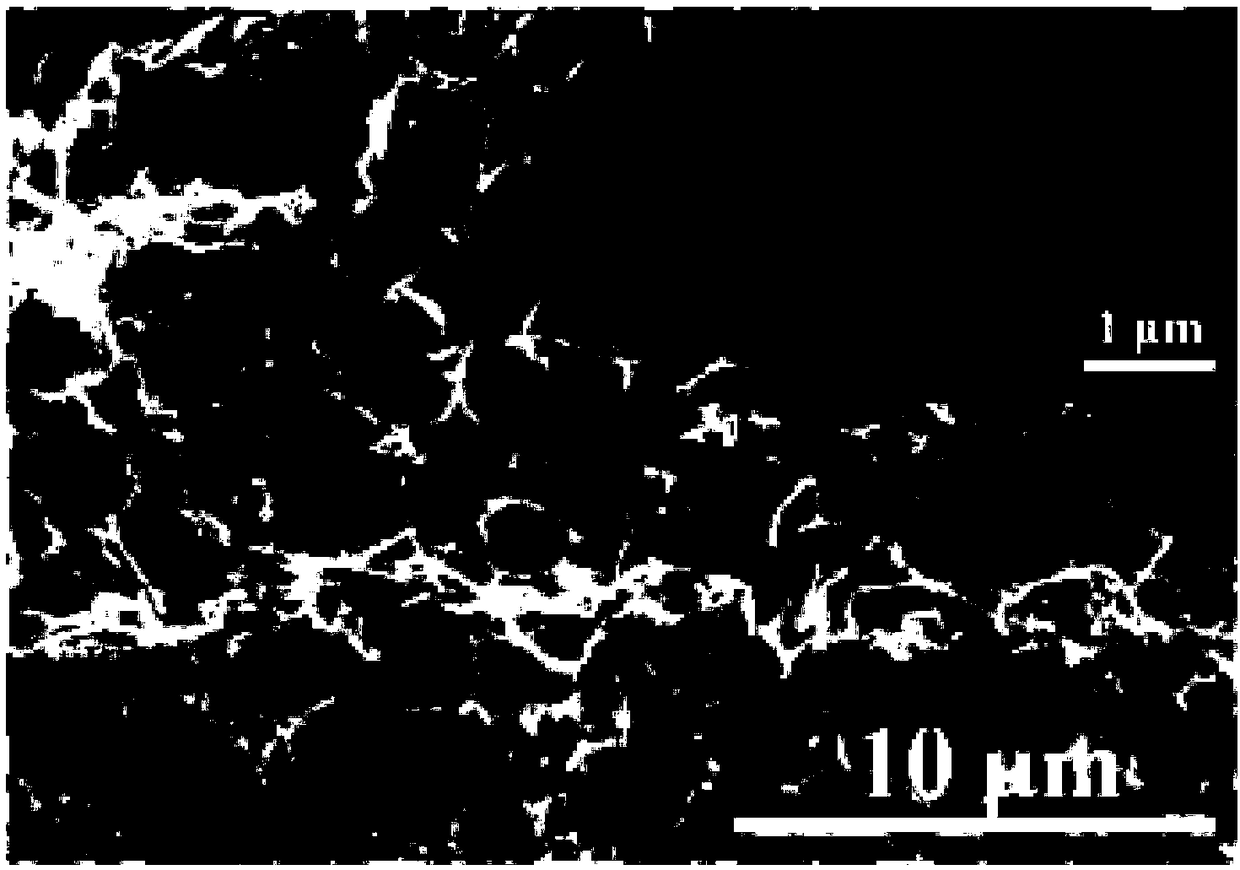

[0030] to combine figure 1 and figure 2 It can be seen that the prepared porous biomass carbon material has a developed three-dimensional mesopore-macropore hierarchical porous structure, and the specific surface area is as high as 1784.79 m 2 / g.

[0031] 2. Mix the porous biomass carbon material prepared in step 1 with 50 mg...

Embodiment 2

[0043] The preparation method of this example is the same as Example 1, except that the argon atmosphere in all steps is adjusted to helium atmosphere protection, and other implementation conditions remain unchanged. Compared with Example 1, the specific capacity and cycle stability of the battery assembled with the porous biomass carbon-based sulfur cathode composite prepared in this example remained basically unchanged, and the initial discharge capacity was as high as 1220 mAh / g at 0.5 C , 823 mAh / g is still maintained after 100 cycles.

Embodiment 3

[0045] The preparation method of this example is the same as that of Example 1, except that the hydrothermal temperature in all steps 1 is 180 °C, the hydrothermal time is 18 h, the calcination temperature for carbonization activation is 900 °C, and other implementation conditions remain unchanged. Compared with Example 1, the specific capacity and cycle stability of the battery assembled with the porous biomass carbon-based sulfur cathode composite prepared in this example were slightly reduced, and the initial discharge capacity was 1177 mAh / g at 0.5 C, and the cycle 100 laps still maintain 769 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com