Pulsating pressure pickling platform

A technology of pulsating pressure and pulsating air pressure, which is applied in the field of pulsating pressure pickling platform, can solve the problems of uncontrollable pickling process, low pickling efficiency, and long food cycle, so as to reduce the degree of human participation, accelerate speed, and improve The effect of safety and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

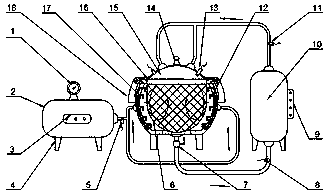

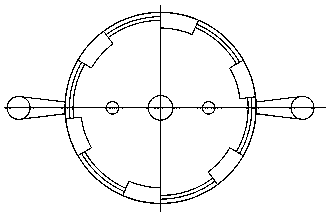

[0020] Example: refer to figure 1 is a pulsating pressure marinating platform. After the air compressor 2 filters the air in the atmosphere, after being detected by the pressure measuring instrument 1, it enters the pickling tank for pressure accumulation, the time relay opens and closes according to the set time, and the electromagnetic pressure relief valve 14 starts to work and unload. In addition to the pressure, repeat the cycle in this way to achieve the purpose of pulsating cycle. By sealing and compressing the handle 18 and using the sealing combination of the sealing rubber ring 16 to carry out sealing treatment, a closed space is formed inside the tank body to ensure the safety and sanitation of the pickling process.

[0021] As preferably: the air pressure of the pulsating air pressure source system first enters the air pressure distribution pipeline 17, and the gas pressure is distributed according to the pipe diameter in the air pressure distribution pipeline 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com