Self assembly polypeptide hydrogel scaffold and preparation method thereof

A hydrogel and self-assembly technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of difficult tissue regeneration, loss, and reduced growth activity of cultured cells, so as to maintain chondrocyte phenotype and promote differentiation role, the effect of promoting deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. 3D printing PCL skeleton:

[0053] FDM rapid extrusion molding, 3D printing heating system heats up to 100 ℃ PCL particles (molecular weight 10000~80000) become viscous fluid, extruded fiber bundles (diameter range 300~500 microns), through different layers of fiber bundles A spliced architecture with angles to obtain a 3D printed skeleton. Each layer of fibers intersects and accumulates in the range of 0~180° to form a triangular structure of 0~60~120°, with a skeleton pore size of 500 microns and a porosity of more than 85%.

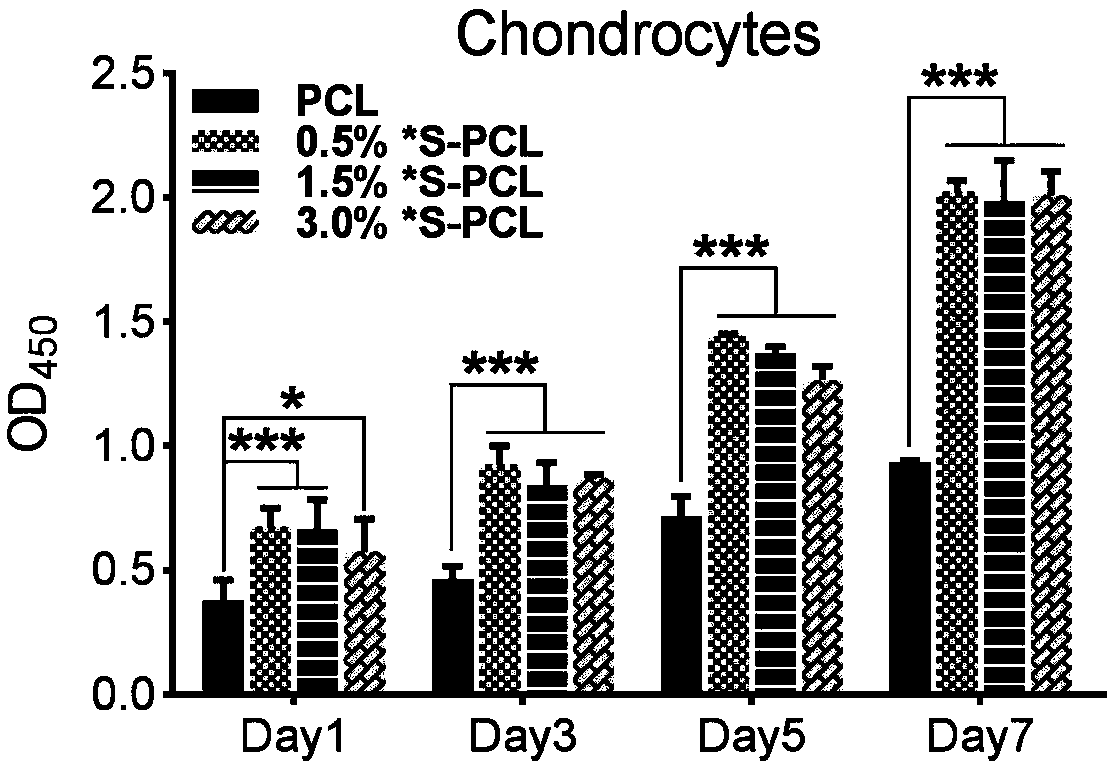

[0054] 2. Preparation of polypeptide self-assembled hydrogel-sol with FE and FK structural units:

[0055] Dissolve FEFEFKFK self-assembled polypeptide (SAP) in double-distilled water to make acidic sol-gel, vortex ultrasonically, heat at 80°C for 1 hour to ensure complete dissolution, and prepare concentrations of 0.5%wt, 1.5%wt and 3.0%wt respectively peptide hydrogels.

[0056] 3. Self-assembled hydrogel-coated PCL scaffolds

[0057]...

Embodiment 2

[0067] The difference between Example 2 and Example 1 is that PLA with a molecular weight of 5,000-40,000 is used for the backbone, and the concentration of the prepared polypeptide hydrogel is 2.0%wt, and the polypeptide used is FEFKFEFK.

Embodiment 3

[0069] The difference between Example 3 and Example 1 is that the backbone part uses PLGA with a molecular weight of 4000-10000, and the concentration of the prepared polypeptide hydrogel is 4.0%wt, and the polypeptide used is FEFEFKFKFEFEFKFK (FEK16).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com