Elevator automatic door pulley assembly special-purpose lubricating oil

A technology for automatic doors and pulley blocks, applied in lubricating compositions, petroleum industry, etc., can solve the problems of equipment safety hazards, increased maintenance costs, and unequal use, and achieve the effects of reducing maintenance costs, saving replacement costs, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

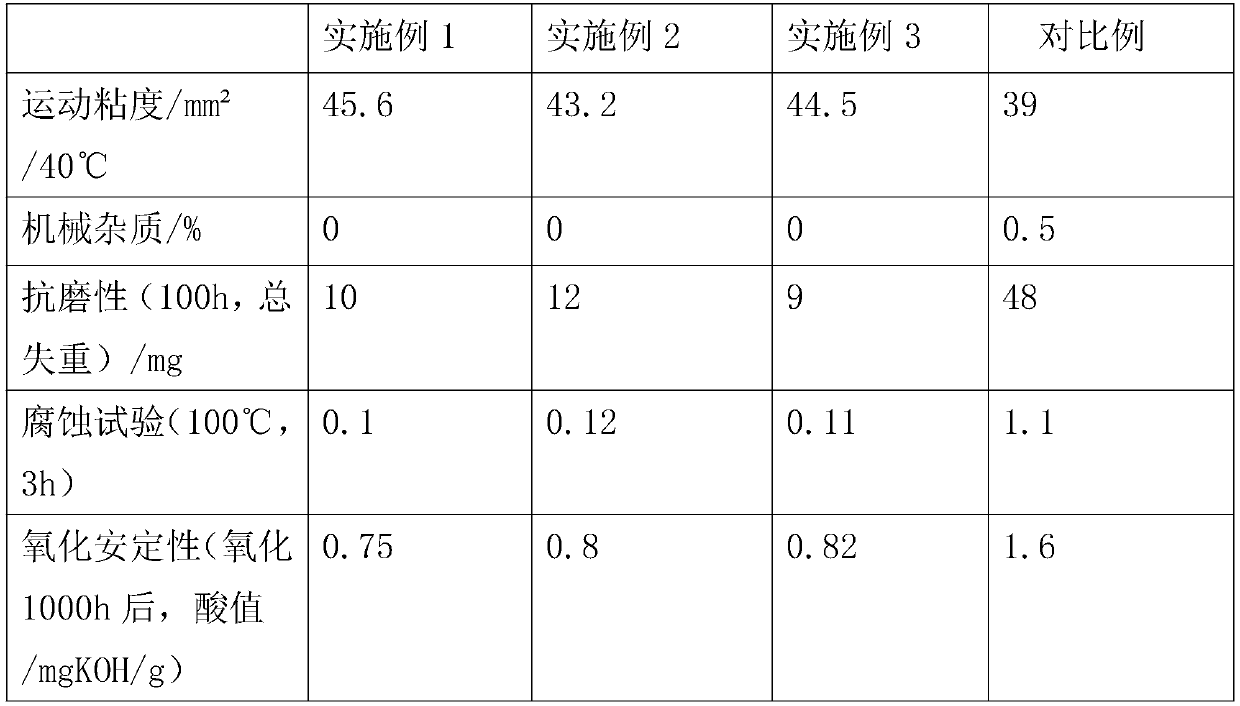

Embodiment 1

[0025] A special lubricating oil for elevator automatic door pulley blocks, which is composed of the following raw materials in parts by weight: 100 parts of base oil, 5 parts of metal anti-wear agent, 5 parts of anti-corrosion and anti-rust agent, 8 parts of cleaning factor, 5 parts of oily agent, metal anti-wear agent 4 parts of activator and 5 parts of viscosity modifier;

[0026] Base oil consists of 20 parts of mineral base oil, 60 parts of rapeseed oil and 40 parts of rice bran oil by weight;

[0027] The cleaning factor is any one or more mixtures of magnesium metal bases, silver metal bases or calcium metal bases;

[0028] The metal antiwear agent is Tieba metal antiwear agent H-grade TRIPAK-9401;

[0029] The anti-corrosion and anti-rust agent is phosphoric acid and / or zinc sulfate;

[0030] The oily agent is composed of polymethyl methacrylate, dioctyl phthalate, SOS oily agent, and sulfurized olefin cottonseed oil-2;

[0031] The metal antiactivator is phosphide ...

Embodiment 2

[0039] A special lubricating oil for elevator automatic door pulley blocks, which is composed of the following raw materials in parts by weight: 110 parts of base oil, 7 parts of metal anti-wear agent, 6 parts of anti-corrosion and anti-rust agent, 9 parts of cleaning factor, 7 parts of oily agent, metal anti-wear agent 6 parts of activator and 7 parts of viscosity modifier;

[0040] The base oil is composed of 30 parts of mineral base oil, 70 parts of rapeseed oil and 50 parts of rice bran oil by weight;

[0041] The cleaning factor is any one or more mixtures of magnesium metal bases, silver metal bases or calcium metal bases;

[0042] The metal antiwear agent is Tieba metal antiwear agent H-grade TRIPAK-9401;

[0043] The anti-corrosion and anti-rust agent is phosphoric acid and / or zinc sulfate;

[0044] The oily agent is composed of polymethyl methacrylate, dioctyl phthalate, SOS oily agent, and sulfurized olefin cottonseed oil-2;

[0045] The metal antiactivator is pho...

Embodiment 3

[0053] A special lubricating oil for elevator automatic door pulley blocks, which is composed of the following raw materials in parts by weight: 105 parts of base oil, 6 parts of metal anti-wear agent, 5.5 parts of anti-corrosion and anti-rust agent, 8.5 parts of cleaning factor, 56 parts of oily agent, metal anti-wear agent 5 parts of activator and 6 parts of viscosity modifier;

[0054] Base oil consists of 25 parts of mineral base oil, 65 parts of rapeseed oil and 45 parts of rice bran oil by weight;

[0055] The cleaning factor is any one or more mixtures of magnesium metal bases, silver metal bases or calcium metal bases;

[0056] The metal antiwear agent is Tieba metal antiwear agent H-grade TRIPAK-9401;

[0057] The anti-corrosion and anti-rust agent is phosphoric acid and / or zinc sulfate;

[0058] The oily agent is composed of polymethyl methacrylate, dioctyl phthalate, SOS oily agent, and sulfurized olefin cottonseed oil-2;

[0059] The metal antiactivator is phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com