Method for comprehensively utilizing low-grade bauxite

A low-grade bauxite and aluminum liquid technology, applied in chemical instruments and methods, aluminum compounds, alkali metal compounds, etc., can solve problems that hinder the normal operation of the production process, avoid hazards, high energy consumption, and overcome the amount of calcium high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, middle and low-grade bauxite is used, and its aluminum-silicon ratio is 3.5, and its main chemical composition (mass percentage, wt%) is:

[0044]Alumina (Al 2 o 3 ): 60.60%

[0045] Silicon dioxide (SiO 2 ): 17.5%

[0046] Iron oxide (Fe 2 o 3 ): 9.8%,

[0047] Titanium dioxide (TiO 2 ): 0.89%

[0048] Others are impurities;

[0049] Lime and carbon soda are common industrial grade products;

[0050] x N = 0.5;

[0051] x C = 1.0.

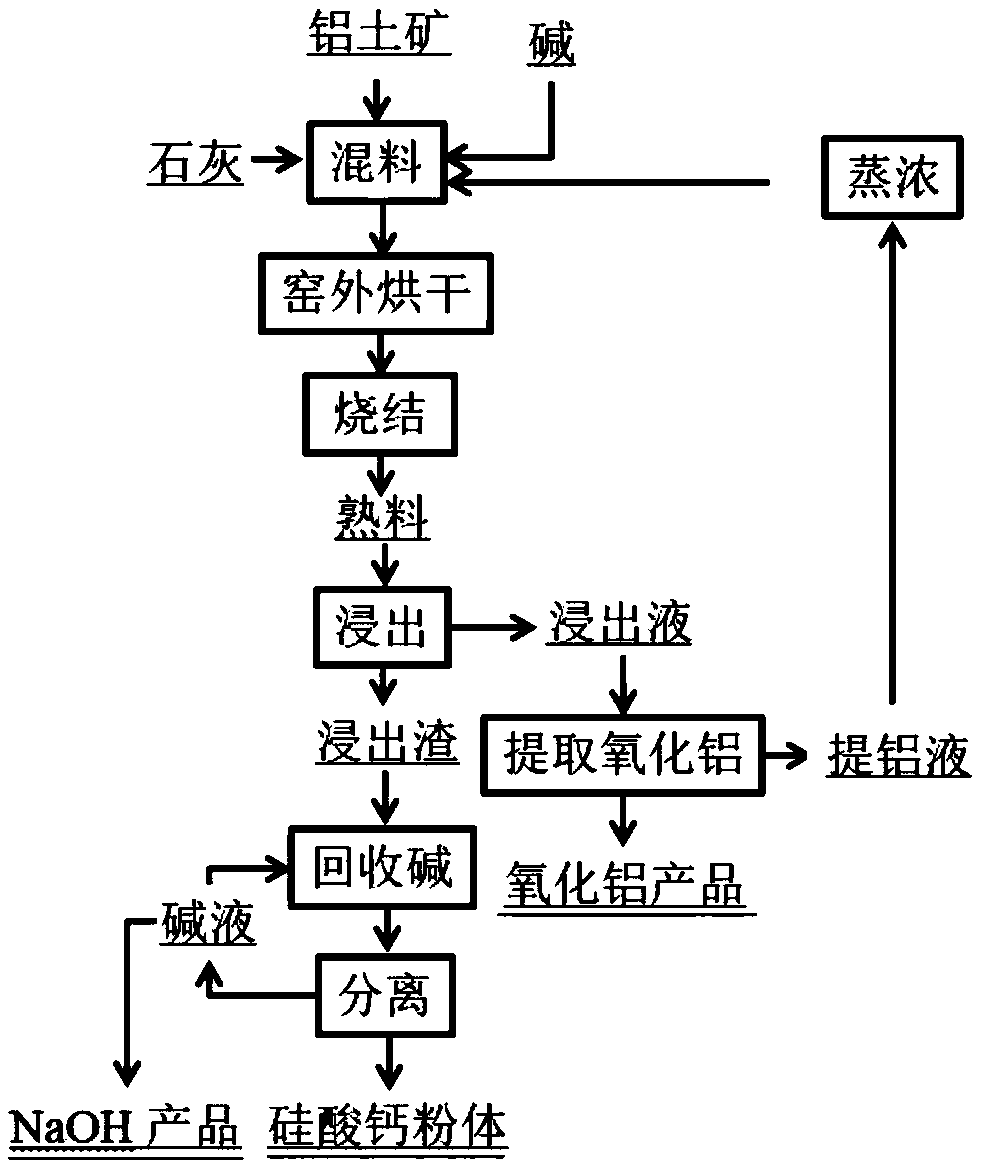

[0052] according to this figure 1 A kind of method for the comprehensive utilization of low-grade bauxite of the present invention shown, comprises the following steps:

[0053] S1: Mix bauxite, lime, carbon soda and circulating mother liquor, and then mix them uniformly in a ball mill to obtain a slurry;

[0054] In this step, in the mixing of the ingredients, a ball mill is used for mixing to obtain a uniform mixed slurry, which is convenient for the processing in the subsequent steps and improves the p...

Embodiment 2

[0071] In this embodiment, middle and low-grade bauxite is used, and its aluminum-silicon ratio is 2.44, and its main chemical composition (mass percentage, wt%) is:

[0072] Alumina (Al 2 o 3 ): 55.22%

[0073] Silicon dioxide (SiO 2 ): 22.66%

[0074] Iron oxide (Fe 2 o 3 ): 7.82%,

[0075] Titanium dioxide (TiO 2 ): 0.63%

[0076] Others are impurities;

[0077] Lime and caustic are common industrial grade products;

[0078] x N = 1.0;

[0079] x C = 1.0.

[0080] according to this figure 1 A kind of method for the comprehensive utilization of low-grade bauxite of the present invention shown, comprises the following steps:

[0081] S1: Mix bauxite, lime, carbon soda and circulating mother liquor, and then mix them uniformly in a ball mill to obtain a slurry;

[0082] In this step, in the mixing of the ingredients, a ball mill is used for mixing to obtain a uniform mixed slurry, which is convenient for the processing in the subsequent steps and improves the p...

Embodiment 3

[0099] In this embodiment, middle and low-grade bauxite is used, and its aluminum-silicon ratio is 4.43, and its main chemical composition (mass percentage, wt%) is:

[0100] Alumina (Al 2 o 3 ): 60.71%

[0101] Silicon dioxide (SiO 2 ): 13.71%

[0102] Iron oxide (Fe 2 o 3 ): 6.31%,

[0103] Titanium dioxide (TiO 2 ): 1.12%

[0104] Others are impurities;

[0105] Lime and caustic are common industrial grade products;

[0106] x N = 1.0;

[0107] x C = 1.5.

[0108] according to this figure 1 A kind of method for the comprehensive utilization of low-grade bauxite of the present invention shown, comprises the following steps:

[0109] S1: Mix bauxite, lime, carbon soda and circulating mother liquor, and then mix them uniformly in a ball mill to obtain a slurry;

[0110] In this step, in the mixing of the ingredients, a ball mill is used for mixing to obtain a uniform mixed slurry, which is convenient for the processing in the subsequent steps and improves the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com