Converter body brick with titanium nitride added and preparation method thereof

A technology of titanium nitride and furnace body bricks, applied in the field of refractory materials, can solve problems such as product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

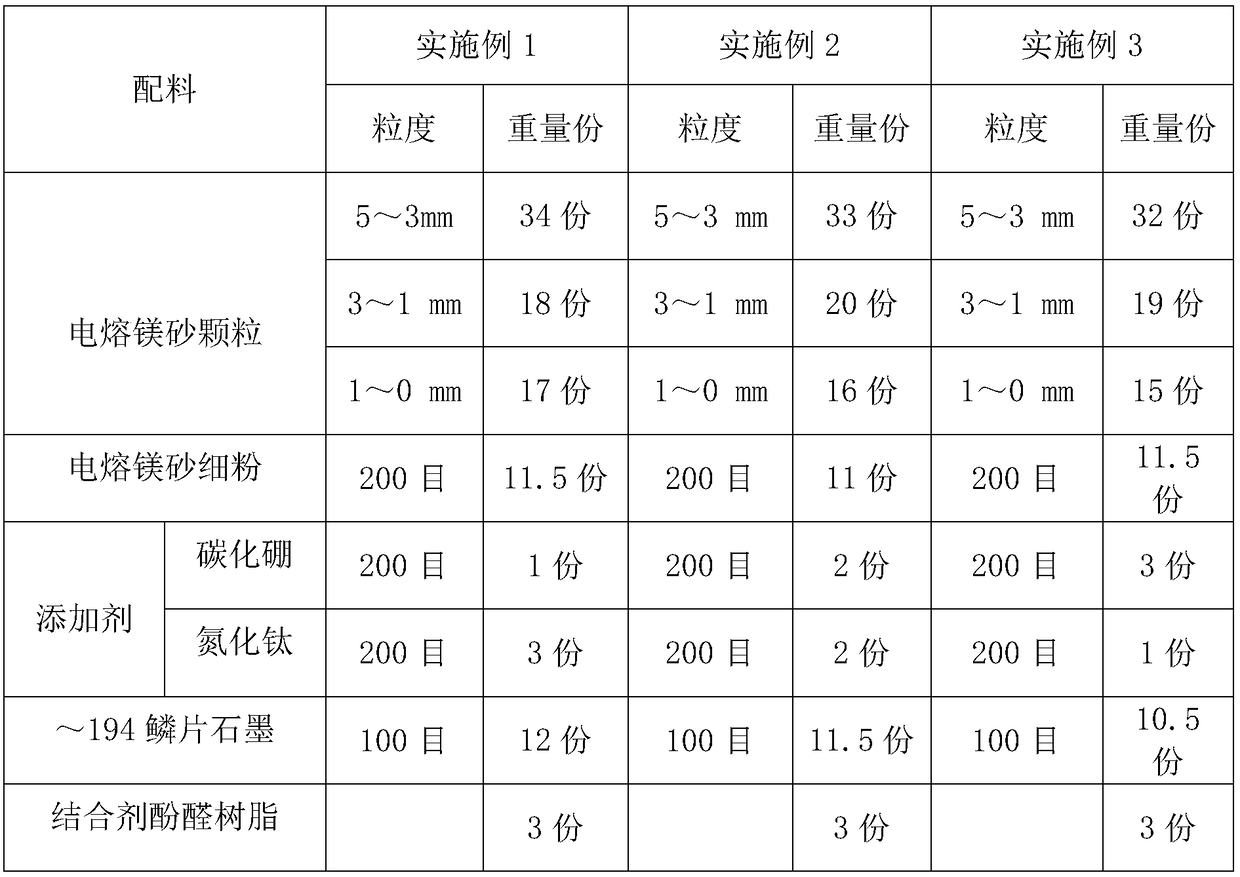

[0024] The following table of 3 kinds of embodiment formulas;

[0025]

[0026] Embodiment 1 The method for preparing converter body bricks, the specific steps are as follows:

[0027] 1) Ingredients: Weigh the raw materials according to the formula in the above table;

[0028] 2) Mixing: Turn on the high-speed mixer, first add the granules in the ingredients and dry mix for 5 minutes, then slowly add the binder phenolic resin and mix for 3 minutes at one time, then add 100 mesh flake graphite and mix for 2 minutes, and finally add the rest The fine powder is mixed together for 20 minutes and then discharged;

[0029] 3) Molding: The mixed mud is molded by 1100t pressure, and the four corners of the cloth are followed when molding, and the principle of lightness first and then heavy is operated;

[0030] 4) Heat treatment: The pressed semi-finished product enters the drying kiln for heat treatment for 24 hours, the temperature at the kiln entrance is 55°C, the preheating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com