Waterborne matte skin-touch coating and preparation method thereof

A water-based, coating technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problem of not having good film formation and crack resistance, water resistance, abrasion resistance and scratch resistance, elongation and bending resistance. It can solve the problems of unsatisfactory interference performance, poor light resistance and yellowing resistance of the coating, and achieve the effects of excellent elongation and resistance to bending, low product modulus, and good yellowing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A water-based matte skin-feeling coating and a preparation method thereof, comprising the following components by mass percentage: polyurethane 8%-88%, water-based elastic resin 5%-90%, matte agent 5%-20%, pH adjustment agent 0.1%-1%, wetting and leveling agent 0.3%-0.9%, hand feeling aid 0.3%-1.2%, curing agent 1%-8%, organic solvent 1%-10%, anti-scratch agent 0.5%-1.8 %.

[0023] Wherein, the polyurethane is water-based polyurethane, and the particle size of the medium-water polyurethane solution is less than 0.001 μm, and the appearance of the polyurethane is transparent.

[0024] Wherein, the polyurethane is one or both of polyether polyurethane or polyester polyurethane.

[0025] Wherein, the water-based elastic resin is a water-based aliphatic polyurethane dispersion, and the water-based aliphatic polyurethane is a water-based elastic PU resin X-PU632 water-based polyurethane.

[0026] Wherein, the matting agent is modified silica matting paste.

[0027] Wherei...

Embodiment 1

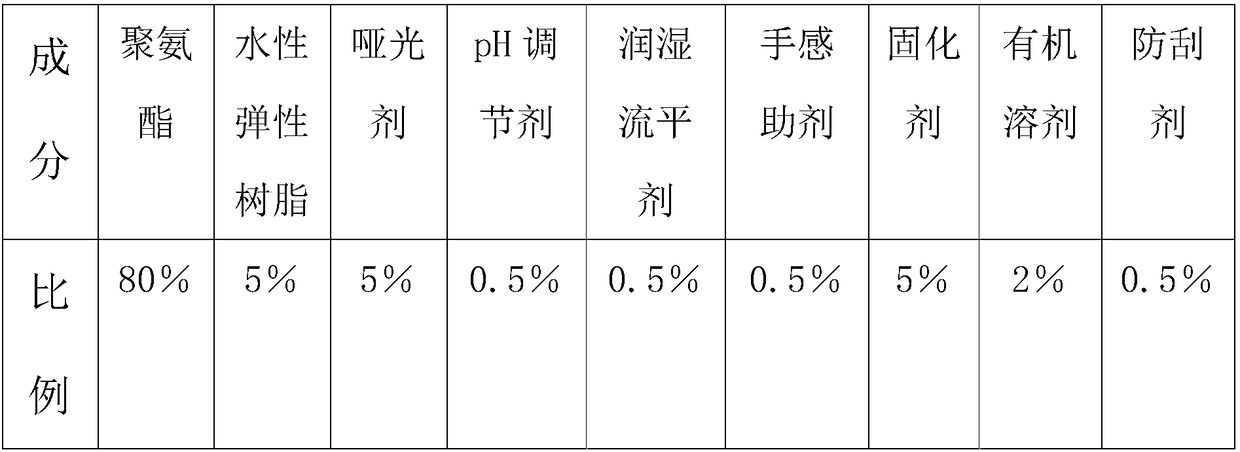

[0032] Embodiment 1, a water-based matte skin-feeling coating and a preparation method thereof, comprising the following components by mass percentage: 80% of polyurethane, 5% of water-based elastic resin, 5% of matte agent, 0.5% of pH adjuster, moisturizing agent Wet leveling agent 0.5%, hand feeling aid 0.5%, curing agent 5%, organic solvent 2%, anti-scratch agent 0.5%.

[0033]

[0034] Include the following steps:

[0035] A: Mix the components according to the stated mass percentage, adjust the mixer speed to 800-900r / min and mix and stir for 30min to prepare a coating water dispersion;

[0036] B: apply the aqueous dispersion of the coating obtained by the A to the substrate, so that the coating obtained by the A is fully reacted and mixed with the substrate;

[0037] C: preheating the coating obtained by the B in a sealed environment at a temperature of 80-130° C. and a time of about 5 min;

[0038] D: The temperature of the coating obtained in the C is about 150° ...

Embodiment 2

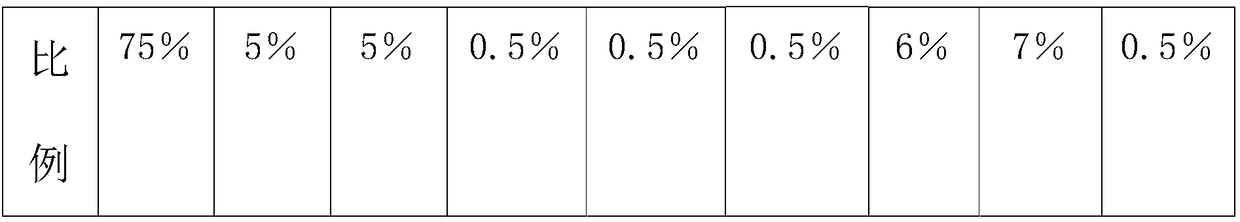

[0039] Embodiment 2, a water-based matte skin-feeling coating and a preparation method thereof, comprising the following components by mass percentage: 75% of polyurethane, 5% of water-based elastic resin, 5% of matte agent, 0.5% of pH adjuster, moisturizing agent Wet leveling agent 0.5%, hand feeling aid 0.5%, curing agent 6%, organic solvent 7%, anti-scratch agent 0.5%.

[0040]

[0041]

[0042] Include the following steps:

[0043] A: Mix the components according to the stated mass percentages, adjust the mixer speed to 900-1000r / min and fully mix and stir for 25min to prepare a coating water dispersion;

[0044] B: apply the aqueous dispersion of the coating obtained by the A to the substrate, so that the coating obtained by the A is fully reacted and mixed with the substrate;

[0045] C: preheating the coating obtained by the B in a sealed environment at a temperature of 80-130° C. and a time of about 5 min;

[0046] D: The temperature of the coating obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com