Preparation method of rose-bengal B/polystyrene/silicon dioxide fluorescent microspheres

A technology of silica and polystyrene, which is applied in the field of surface modification of composite nanomaterials, can solve the problems of easily agglomerated dye molecules and materials, poor monodispersity, and difficulty in general application, etc., and achieve stable fluorescence performance and good dispersion , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

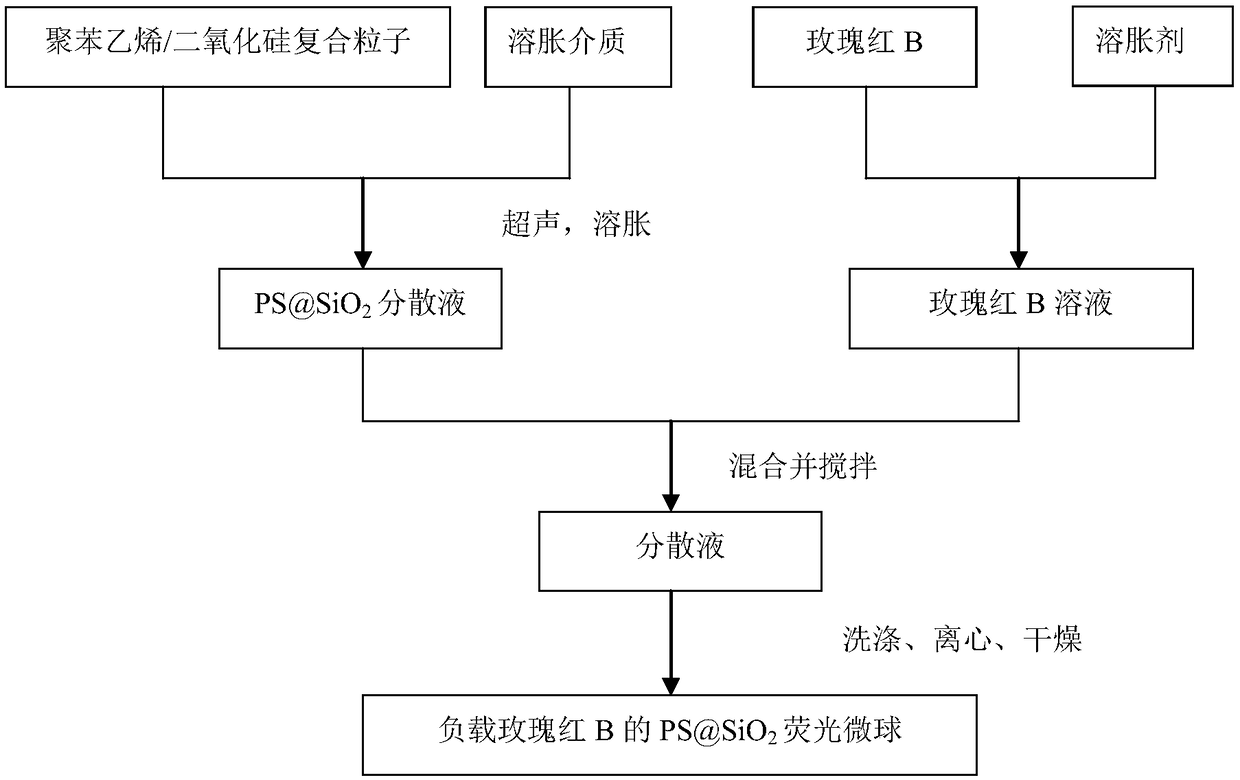

Method used

Image

Examples

Embodiment 1

[0031] (1) Disperse 5.0 g of polystyrene / silica composite particles in 45ml of deionized water, ultrasonicate for 30 minutes, and swell for 3 hours to obtain a polystyrene / silica dispersion with a mass fraction of 10%;

[0032] (2) Dissolve 0.7185g of Rose Red B in 100ml of chloroform, pipette 1000μL of the solution with a pipette, and add it to 9ml of chloroform to make a concentration of 1.5*10 -3 mol.L -1 Rose Bengal B solution;

[0033] (3) Mix 6ml of Rose Bengal B solution obtained in step (2) with 35ml of polystyrene / silica dispersion obtained in step (1), stir and react at 60°C for 6h. After the reaction, use absolute ethanol Wash, centrifuge at 12000 rpm for 10 minutes, remove the supernatant, repeat the operation 3 times, and then dry in a blast drying oven at 55°C for 24 hours to obtain rose bengal B-loaded polystyrene / silica fluorescent microspheres .

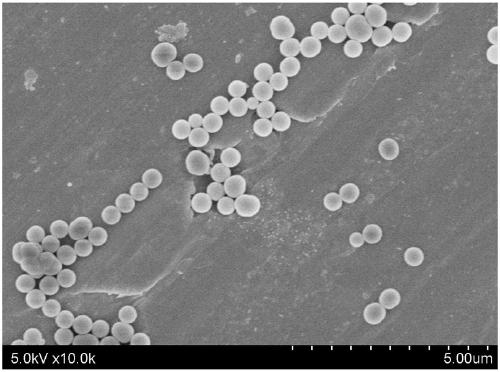

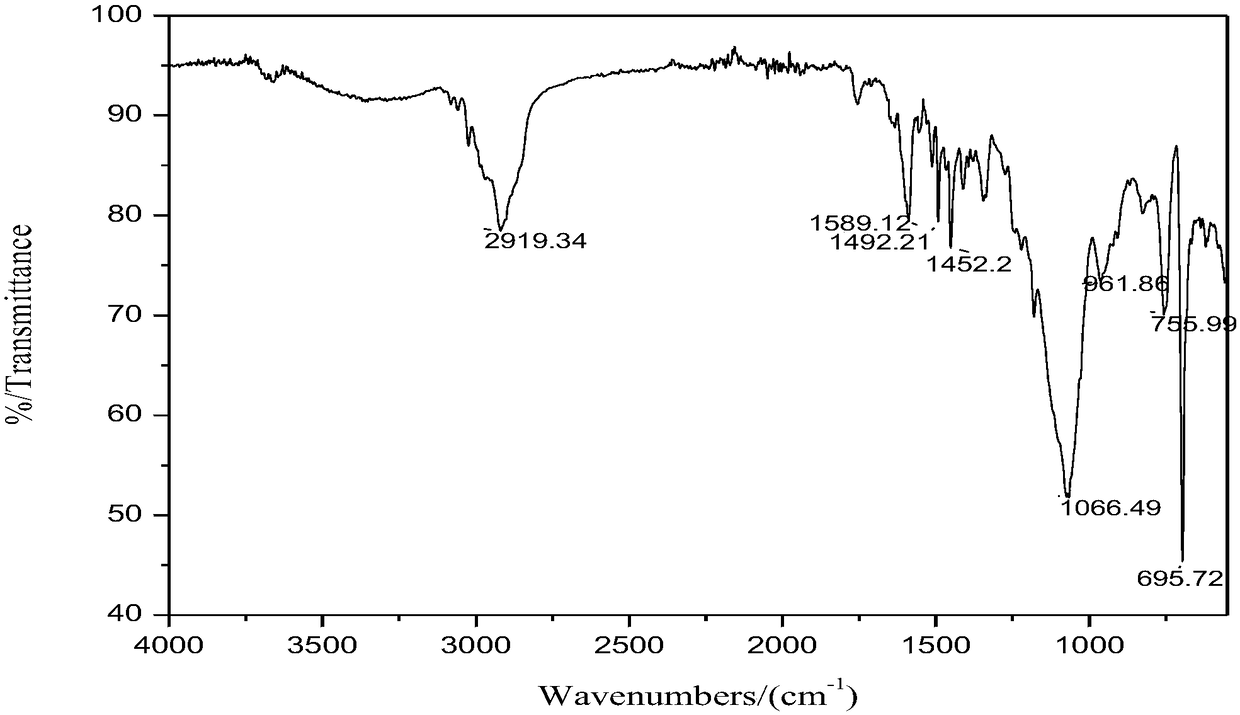

[0034] The SEM results of the rose bengal B-loaded polystyrene / silica fluorescent microspheres prepared in this example ...

Embodiment 2

[0039] (1) Disperse 5.0 g of polystyrene / silica composite particles in 45ml of deionized water, ultrasonicate for 30 minutes, and swell for 3 hours to obtain a polystyrene / silica dispersion with a mass fraction of 10%;

[0040] (2) Dissolve 0.2874g of Rose Red B in 100ml of chloroform, pipette 1000μL of the solution with a pipette, and add it to 9ml of chloroform to make a concentration of 6.0*10 -4 mol.L -1 Rose Bengal B solution;

[0041] (3) Mix 6ml of Rose Bengal B solution obtained in step (2) with 35ml of polystyrene / silica dispersion obtained in step (1), stir and react at 60°C for 6h. After the reaction, use absolute ethanol Wash, centrifuge at 12000 rpm for 10 minutes, remove the supernatant, repeat the operation 3 times, and then dry in a blast drying oven at 55°C for 24 hours to obtain rose bengal B-loaded polystyrene / silica fluorescent microspheres .

[0042] The Rose Bengal B-loaded polystyrene / silica fluorescent microspheres prepared in this example were dispersed in w...

Embodiment 3

[0044] (1) Disperse 5.0g of polystyrene / silica composite particles in 45ml of deionized water, ultrasonicate for 30min, and swell for 3h to obtain a polystyrene / silica dispersion with a mass fraction of 10%;

[0045] (2) Dissolve 0.1437g of Rose Bengal B in 100ml of chloroform, pipette 1000μL of the solution with a pipette, and add it to 9ml of chloroform to prepare a concentration of 3.0*10 -4 mol.L -1 Rose Bengal B solution;

[0046] (3) Mix 6ml of Rose Bengal B solution obtained in step (2) with 35ml of polystyrene / silica dispersion obtained in step (1), stir and react at 60°C for 6h. After the reaction, use absolute ethanol Wash, centrifuge at 12000 rpm for 10 minutes, remove the supernatant, repeat the operation 3 times, and then dry in a blast drying oven at 55°C for 24 hours to obtain rose bengal B-loaded polystyrene / silica fluorescent microspheres .

[0047] The polystyrene / silica fluorescent microspheres loaded with Rose Bengal B prepared in this example were dispersed in d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| fluorescence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com