Additives for electrolytic copper foil and its application, electrolytic copper foil and its preparation method and application, lithium ion battery

A technology of electrolytic copper foil and additives, applied in the field of electrolytic copper foil, can solve problems such as copper foil warping, copper foil folds, problems, etc., and achieve the effects of fine crystallization, uniform thickness, and low warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

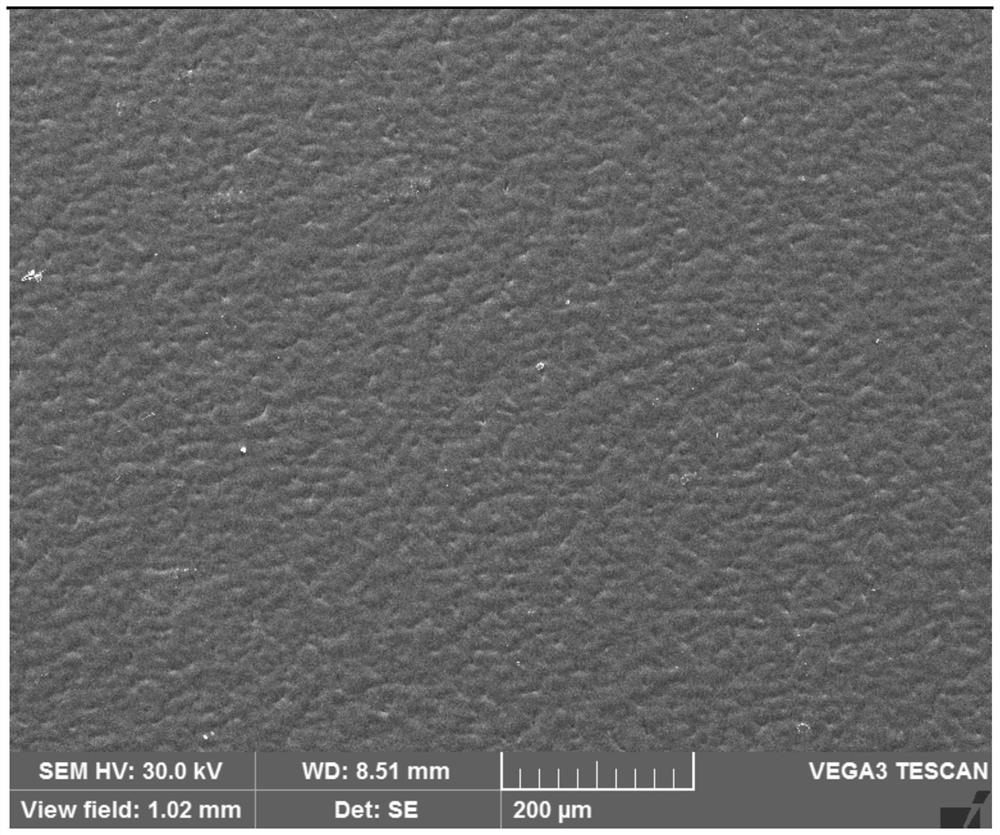

Image

Examples

preparation example Construction

[0069] According to a third aspect of the present invention, a method for preparing an electrolytic copper foil is provided, comprising the following steps:

[0070] adding additive A and additive B into the electrolyte, electrolytically making foil, and obtaining electrolytic copper foil;

[0071] Wherein, the copper ion content in the electrolyte is 60-120g / L, the sulfuric acid content is 80-150g / L, and the chloride ion content is 10-30ppm.

[0072] It should be noted that the electrolyte can be obtained by adding hydrochloric acid to the copper sulfate electrolyte. Among them, the temperature for preparing the electrolyte is 45-55°C, and the typical but non-limiting temperatures for preparing the electrolyte are 45°C, 46°C, 47°C, 48°C, 49°C, 50°C, 51°C, 51°C, 52°C , 53°C or 55°C; the electrolyte can be effectively prepared by adjusting the temperature reasonably.

[0073] In the present invention, the electrolytic copper foil can be obtained by adding the additive A and t...

Embodiment 1

[0093] (1) Additives for electrolytic copper foil

[0094] An additive for electrolytic copper foil, including additive A and additive B.

[0095] Among them, additive A includes sodium polydithiodipropane sulfonate SPS and polyethyleneimine alkyl compound GISS, and the weight ratio of SPS and GISS is 12:6;

[0096] Additive B includes collagen Q (the average number average molecular weight of collagen Q is 1200) and carboxymethyl chitosan CC, and the weight ratio of Q and CC is 15:2.

[0097] (2) Preparation of additive aqueous solution for electrolytic copper foil

[0098] An aqueous solution of an additive for electrolytic copper foil, comprising an aqueous solution of additive A and an aqueous solution of additive B.

[0099] SPS and GISS with a weight ratio of 12:6 were dissolved in water to obtain an aqueous solution of additive A, wherein the content of SPS was 12 g / L and the content of GISS was 6 g / L.

[0100] Dissolve Q and CC at a weight ratio of 15:2 in hot water...

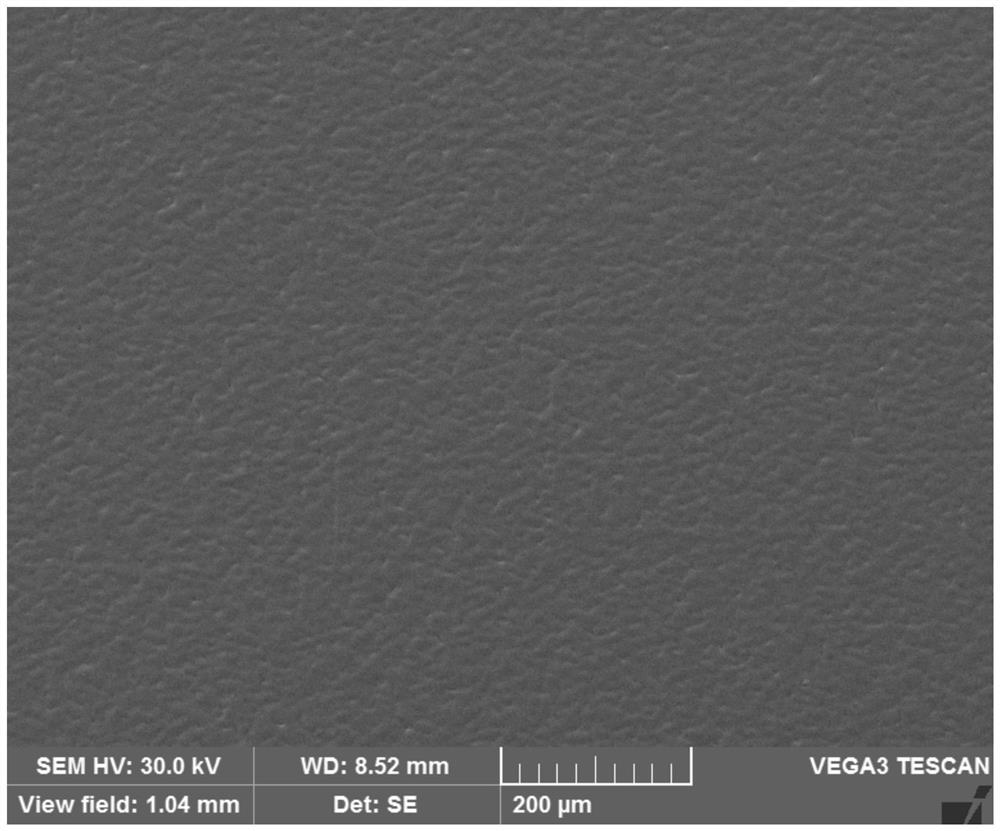

Embodiment 2

[0114] (1) Preparation of additive aqueous solution for electrolytic copper foil

[0115] An aqueous solution of an additive for electrolytic copper foil, comprising an aqueous solution of additive A and an aqueous solution of additive B.

[0116] SPS and GISS with a weight ratio of 13:5 were dissolved in water to obtain an aqueous solution of additive A, wherein the content of SPS was 13 g / L and the content of GISS was 5 g / L.

[0117] Q and CC with a weight ratio of 14:4 were dissolved in hot water at 50°C to obtain an aqueous solution of additive B, wherein the content of Q was 14 g / L and the content of CC was 4 g / L.

[0118] (2) Preparation method of electrolytic copper foil

[0119] A preparation method of electrolytic copper foil, comprising the following steps:

[0120] ① Preparation of electrolyte: add hydrochloric acid to copper sulfate electrolyte to obtain electrolyte, and the preparation temperature is 45°C; filter the obtained electrolyte and add it to the clean ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com