A method and device for removing impurities in chlorosilane

A technology for the separation and purification of chlorosilanes and impurities, which is applied in the field of separation and purification of chlorosilanes, which can solve the problems of high equipment investment costs, unstable product quality, and high energy consumption, and achieve the effects of improving product quality, improving and stabilizing quality, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment is above figure 2 The device reacts, and the gas-phase chlorosilane containing impurities is treated with a physical adsorbent to obtain the treated gas-phase chlorosilane; the physical adsorbent includes a porous solid carrier and a first component. The first component is Acetamide, the porous solid carrier is benzonitrile, wherein the mass percentage of acetamide in the physical adsorbent is 0.5%.

[0039] The carbon organic impurity content of chlorosilane was measured before and after treatment, and the results are shown in Table 1.

Embodiment 2

[0041] This embodiment is above figure 2 The device reacts, and the gas-phase chlorosilane containing impurities is treated with a physical adsorbent to obtain the treated gas-phase chlorosilane; the physical adsorbent includes a porous solid carrier and a first component. The first component is Polyaluminum chloride, the porous solid carrier is silicon aluminum oxide, wherein the mass percentage of polyaluminum chloride in the physical adsorbent is 0.2%.

[0042] Measure the carbon organic impurity content of chlorosilane before and after treatment, the result is as follows figure 1 shown.

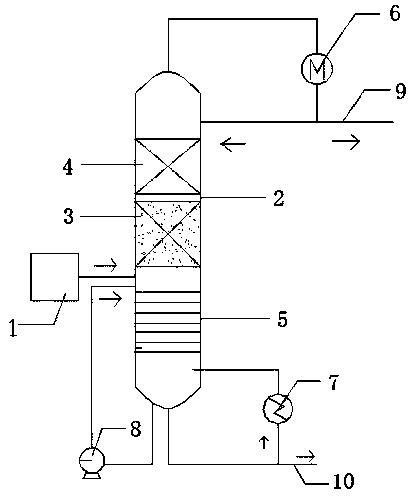

[0043] Such as image 3 Shown: the present invention adopts following physical adsorption to remove the device of impurity in chlorosilane:

[0044]The device is a rectification tower 2, and the rectification tower 2 is provided with a rectification section 4, an adsorption-desorption section 3 and a stripping section 5; a tower top condenser 6 is arranged on the rectification section...

Embodiment 3

[0046] This embodiment is above image 3 The device is used for the production of high-purity chlorosilanes, and heterochlorosilanes are passed into the reactive distillation column 2 from the inlet of chlorosilanes. After the reaction, part of the products pass through the circulation pump 8 from the bottom of the column in the rectification section 4 and the adsorption and desorption section 3. The middle is passed into the reactive distillation column 2, the operating pressure range of the rectification column 2 is 1MPa, the operating temperature range of the top of the tower is 150°C, the reflux feed ratio range is 20, the rectification section 4 and the stripping section 5 trays The number is 200, and the structured packing is stainless steel plate corrugated packing; wherein the physical adsorbent includes a porous solid carrier and a first component, the porous solid carrier is silica gel, and the first component is aniline, wherein the aniline is in the physical adsorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com