A rotary low temperature hydrogen isotope separation system and separation method

A hydrogen isotope and separation system technology, applied in the field of nuclear technology, can solve the problems of complicated separation column regeneration, expensive palladium displacement chromatographic packing, and complicated parameter control, and achieve the effects of cheap packing, reduced construction cost, and simple parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] Example 1: Hydrogen isotope separation in single cycle mode

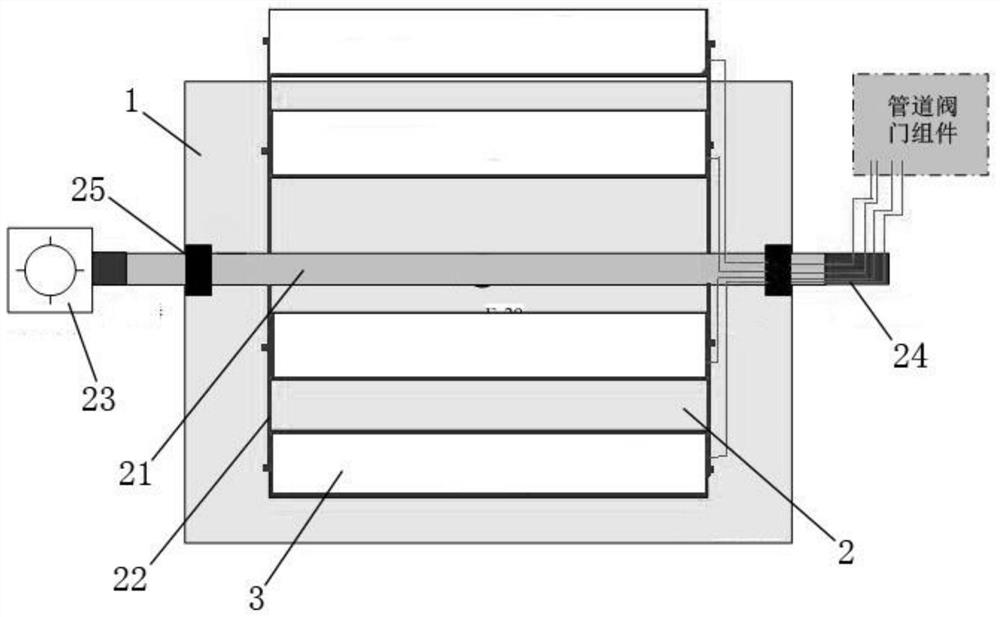

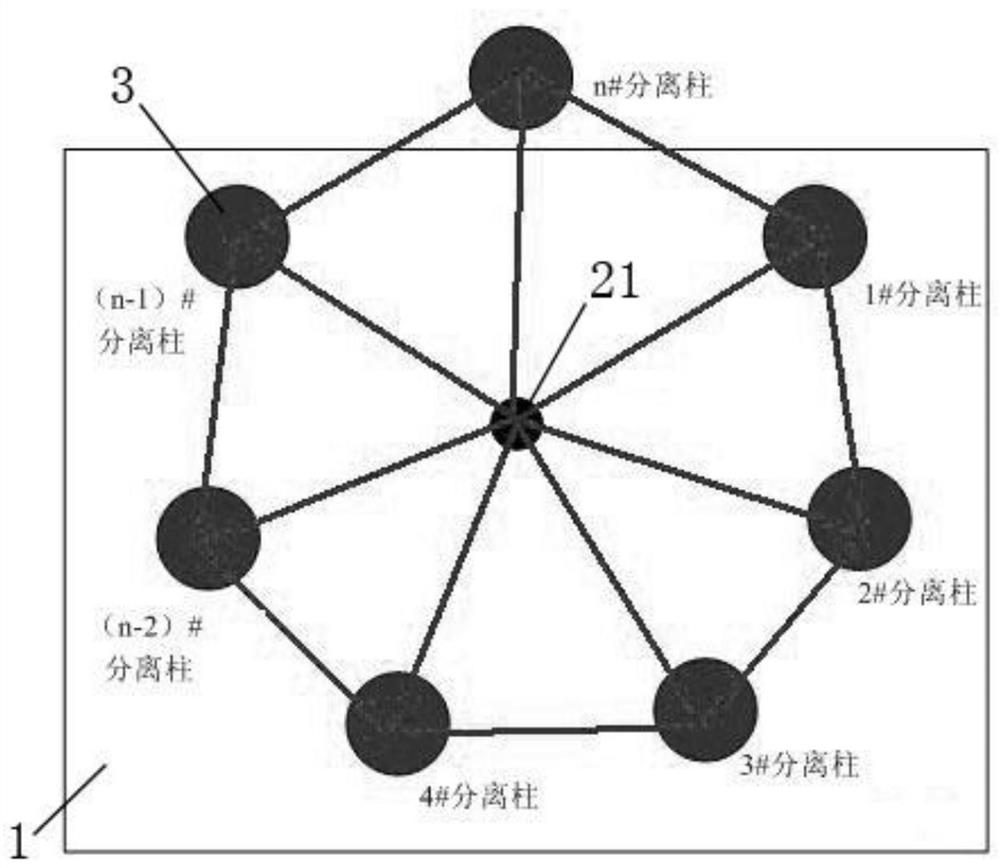

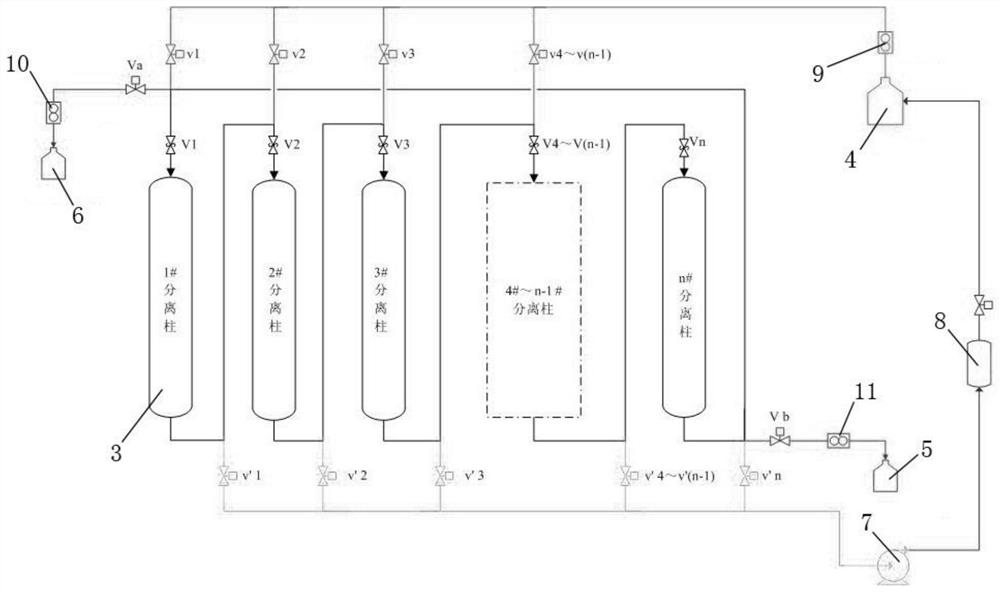

[0050] In this example, 8 separation columns are selected, namely 1#, 2#, 3#, 4#, 5#, 6#, 7# and 8# separation columns, and each separation column is numbered (1#→2#→...→ 8#→1#) are connected end to end in a clockwise direction to form a closed loop; the turret on which the separation column is placed is placed in a low-temperature tank, and the low-temperature tank is cooled by liquid nitrogen. The separation column on the top of the turret is above the liquid level, and the rest of the The column is submerged below the liquid surface. The example system also includes raw material hydrogen storage tanks, light isotope storage tanks, heavy isotope storage tanks, tail gas storage tanks, flow meters, vacuum pumps, and pipes and valves connecting the above devices.

[0051] The separation column is a stainless steel bellows with an outer diameter of DN50, a wall thickness of 0.2mm, and a length of 1000. The pre...

example 2

[0062] Example 2: Natural Hydrogen Separation in Dual Cycle Mode

[0063] The rotary type low temperature hydrogen isotope separation system selected by example 2 is the same as example 1, and the specific separation method is as follows:

[0064] 1, carry out the operation of step (1)~(6) among the example 1, complete a cycle separation;

[0065] Ⅱ, repeat the operation of step (1)~(6) among the example 1, complete the second cycle separation;

[0066] Ⅲ. Connect the pipeline of the light isotope storage tank, move the rotating frame clockwise, so that the 7# separation column rises out of the liquid surface, the isotope in the column is desorbed, and the light isotope is discharged from the bottom of the column. The concentration is about 1ppm; connect the heavy isotope storage tank pipeline, move the rotating frame counterclockwise, so that the 1# separation column rises out of the liquid surface, and the heavy isotope is discharged from the top of the column. The collecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com