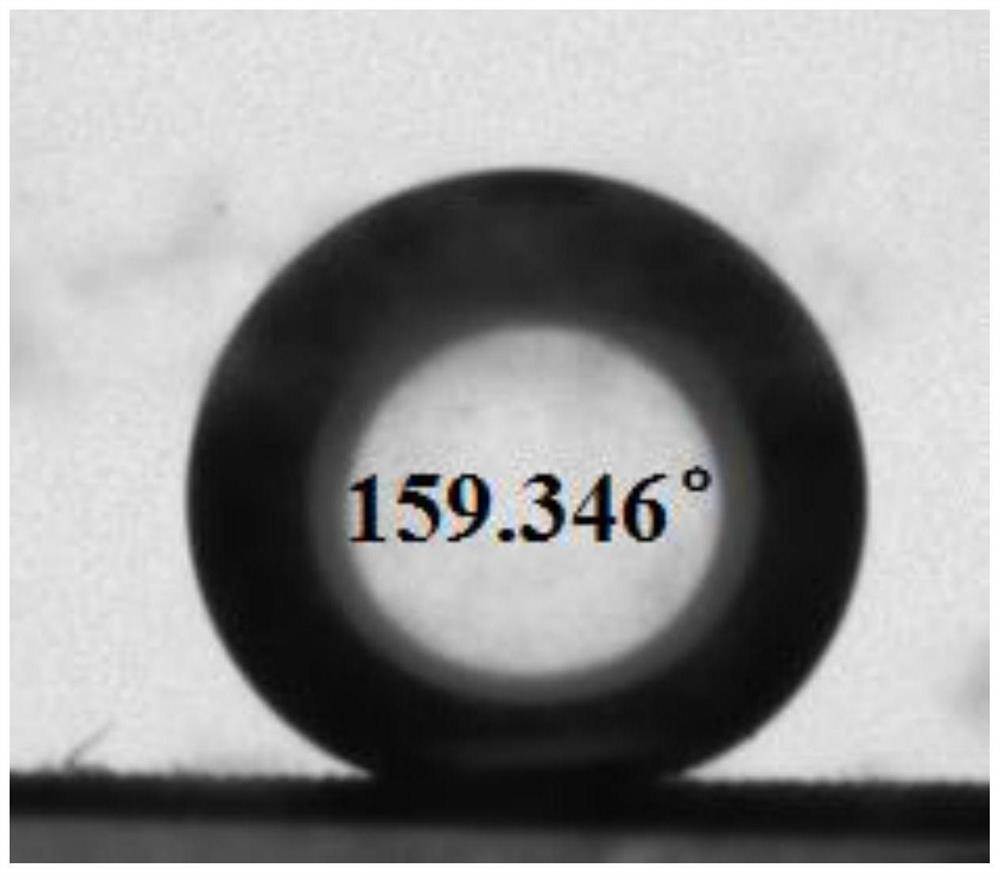

A cobalt oxide/sio 2 Preparation method and application of composite omentum

A cobalt oxide, omentum technology, applied in the field of nano-functional omentum material preparation technology, can solve the problems of inability to simultaneously realize dual functions of oil-water separation and antibiotic catalytic degradation, complex equipment requirements, single functionalization, etc. The effect of dual functions of oil-water separation, single experimental equipment and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) dissolving cobalt chloride in ethanol solution to obtain a cobalt chloride ethanol solution with a mass percent concentration of 1%; ultrasonically vibrating for subsequent use;

[0032] (2) Dissolving tetraethyl orthosilicate in ethanol solution to obtain tetraethyl orthosilicate ethanol solution with a concentration of 1% by mass; ultrasonically oscillate for subsequent use;

[0033] (3) After cutting the stainless steel mesh, put it into acetone and ethanol solution for ultrasonic treatment for 25 minutes;

[0034] (4) Immerse the stainless steel mesh treated in step (3) in the tetraethyl orthosilicate ethanol solution prepared in step (2) for 1 min, then take out the stainless steel mesh and burn it with an alcohol blowtorch for 40 seconds;

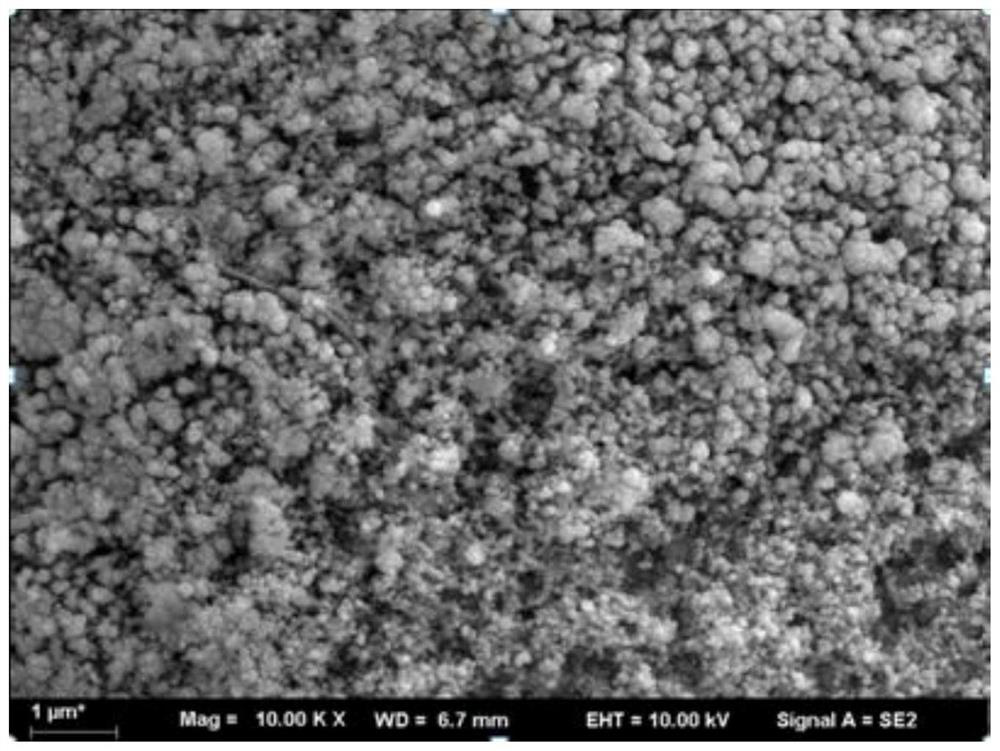

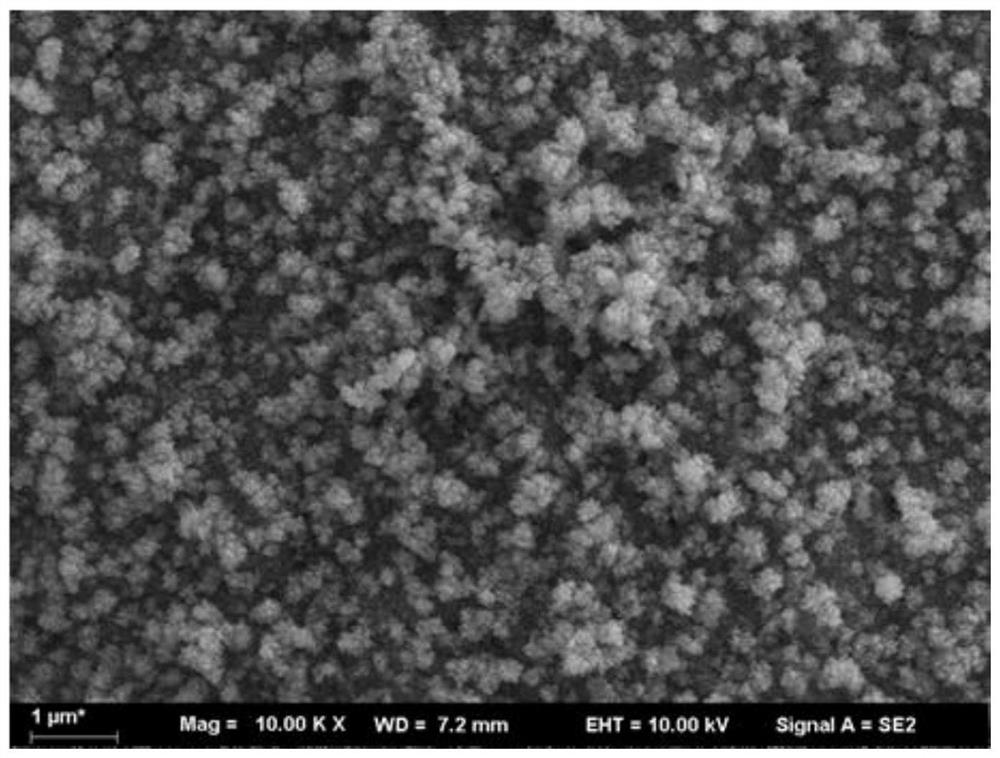

[0035] (5) Immerse the stainless steel net treated in step (4) in the cobalt chloride ethanol solution configured in step (1) for 1 min, then take out the stainless steel net and burn it for 40 seconds to obtain cobalt oxid...

Embodiment 2

[0038] (1) Cobalt chloride is dissolved in ethanol solution to obtain a cobalt chloride ethanol solution with a mass percentage concentration of 1.5%; ultrasonic vibration is used for subsequent use;

[0039] (2) Dissolving tetraethyl orthosilicate in ethanol solution to obtain a tetraethyl orthosilicate ethanol solution with a concentration of 3% by mass; ultrasonically vibrate and set aside;

[0040] (3) After cutting the stainless steel mesh, put it into acetone and ethanol solution for ultrasonic treatment for 20 minutes;

[0041] (4) Immerse the stainless steel net treated in step (3) in the tetraethyl orthosilicate ethanol solution configured in step (2) for 40 seconds, then take out the stainless steel net and burn it for 50 seconds;

[0042] (5) Immerse the stainless steel net treated in step (4) in the cobalt chloride ethanol solution configured in step (1) for 40s, then take out the stainless steel net and burn it with an alcohol blowtorch for 50s to obtain cobalt ox...

Embodiment 3

[0045] (1) Cobalt chloride is dissolved in ethanol solution to obtain a cobalt chloride ethanol solution with a mass percentage concentration of 3%; ultrasonic vibration is used for subsequent use;

[0046] (2) Dissolving tetraethyl orthosilicate in ethanol solution to obtain tetraethyl orthosilicate ethanol solution with a concentration of 8% by mass; ultrasonically oscillate for subsequent use;

[0047] (3) After cutting the stainless steel mesh, put it into acetone and ethanol solution for ultrasonic treatment for 30 minutes;

[0048] (4) Immerse the stainless steel net treated in step (3) in the tetraethyl orthosilicate ethanol solution configured in step (2) for 30 seconds, then take out the stainless steel net and burn it for 40 seconds;

[0049] (5) Immerse the stainless steel mesh treated in step (4) in the cobalt chloride ethanol solution configured in step (1) for 30s, then take out the stainless steel mesh and burn it with an alcohol blowtorch for 40s to obtain coba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com