Preparation method and application of cobalt oxide supported composite mesh film bifunctional material

A bifunctional material, cobalt oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, separation methods, etc. Complex equipment requirements, single functionalization and other problems, to achieve the dual functions of catalysis and oil-water separation, increase roughness, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

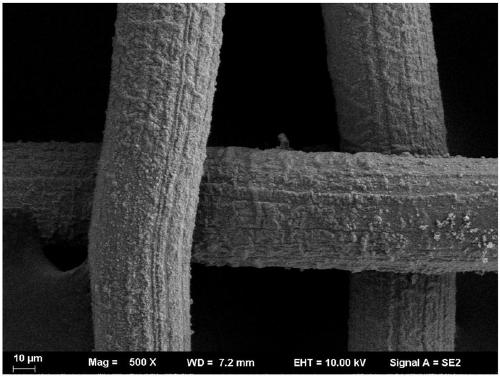

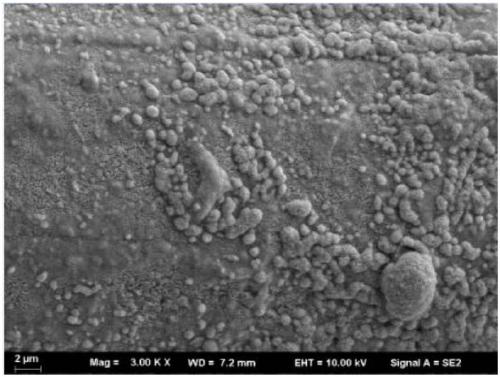

[0025] Dissolve the cobalt chloride in the ethanol solution to obtain a cobalt chloride ethanol solution with a mass percentage concentration of 0.5%, perform ultrasonic oscillation for 15 minutes, fully dissolve, and wait for use; after the stainless steel mesh is appropriately cut, put it in acetone and ethanol solutions in turn Ultrasonic treatment was carried out for 60 min; then the treated stainless steel mesh was immersed in a cobalt chloride ethanol solution for 30 s, and then the stainless steel mesh was taken out and burned under the external flame of an alcohol lamp for 40 s to obtain a cobalt oxide-supported omentum bifunctional material.

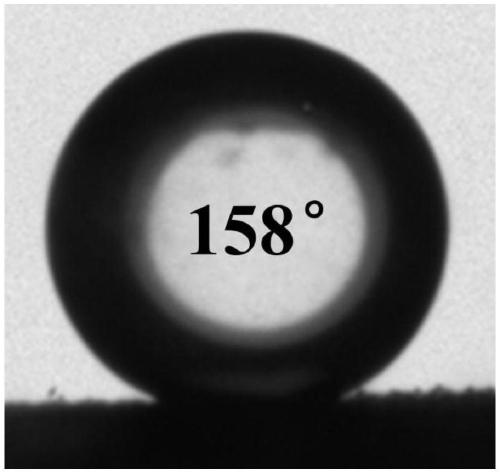

[0026] Pad the bifunctional material of the cobalt oxide loaded omentum in the PTFE flange, assemble the oil-water separation device, weigh the persulfate at a concentration of 5 mmol / L and add it to the oil-water mixture to be treated, and pour the oil-water mixture into the oil-water mixture. In the quartz tube, it was found th...

Embodiment 2

[0028] Dissolve cobalt chloride in an ethanol solution to obtain a cobalt chloride ethanol solution with a mass percentage concentration of 3%, perform ultrasonic vibration for 25 minutes, fully dissolve, and wait for use; after appropriately cutting the stainless steel mesh, put it into acetone and ethanol solutions in turn Ultrasonic treatment was carried out for 90 min; then the treated stainless steel mesh was immersed in a cobalt chloride ethanol solution for 60 s, and then the stainless steel mesh was taken out and burned under the external flame of an alcohol lamp for 60 s to obtain a cobalt oxide-supported omentum bifunctional material.

[0029] Pad the bifunctional material of the cobalt oxide-loaded omentum in the PTFE flange, assemble the oil-water separation device, weigh the persulfate at a concentration of 7.5 mmol / L and pour it into the oil-water mixture to be treated. Pour it into the quartz tube, and find that the oil is blocked above the flange, and the water ...

Embodiment 3

[0031] Dissolve cobalt chloride in an ethanol solution to obtain a cobalt chloride ethanol solution with a mass percentage concentration of 1.5%, perform ultrasonic vibration for 30 minutes, fully dissolve, and stand by for use; after appropriately cutting the stainless steel mesh, put it into acetone and ethanol solutions in turn Ultrasonic treatment was carried out for 120 min; then the treated stainless steel mesh was immersed in a cobalt chloride ethanol solution for 45 s, and then the stainless steel mesh was taken out and burned under the external flame of an alcohol lamp for 45 s to obtain a cobalt oxide-supported omentum bifunctional material.

[0032] Pad the bifunctional material of the cobalt oxide loaded omentum in the PTFE flange, assemble the oil-water separation device, weigh the persulfate at a concentration of 10 mmol / L and pour it into the oil-water mixture to be treated, and pour it into the In the quartz tube, it was found that the oil was blocked above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com