Green synthesis method and application of steamed bread-structured nano-Cu2O

A technology of green synthesis and steamed bread, applied in the direction of nanotechnology, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of harsh reaction conditions, uncontrollable reactions, toxic and side effects, etc., and achieve low equipment requirements, low cost, and good circulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

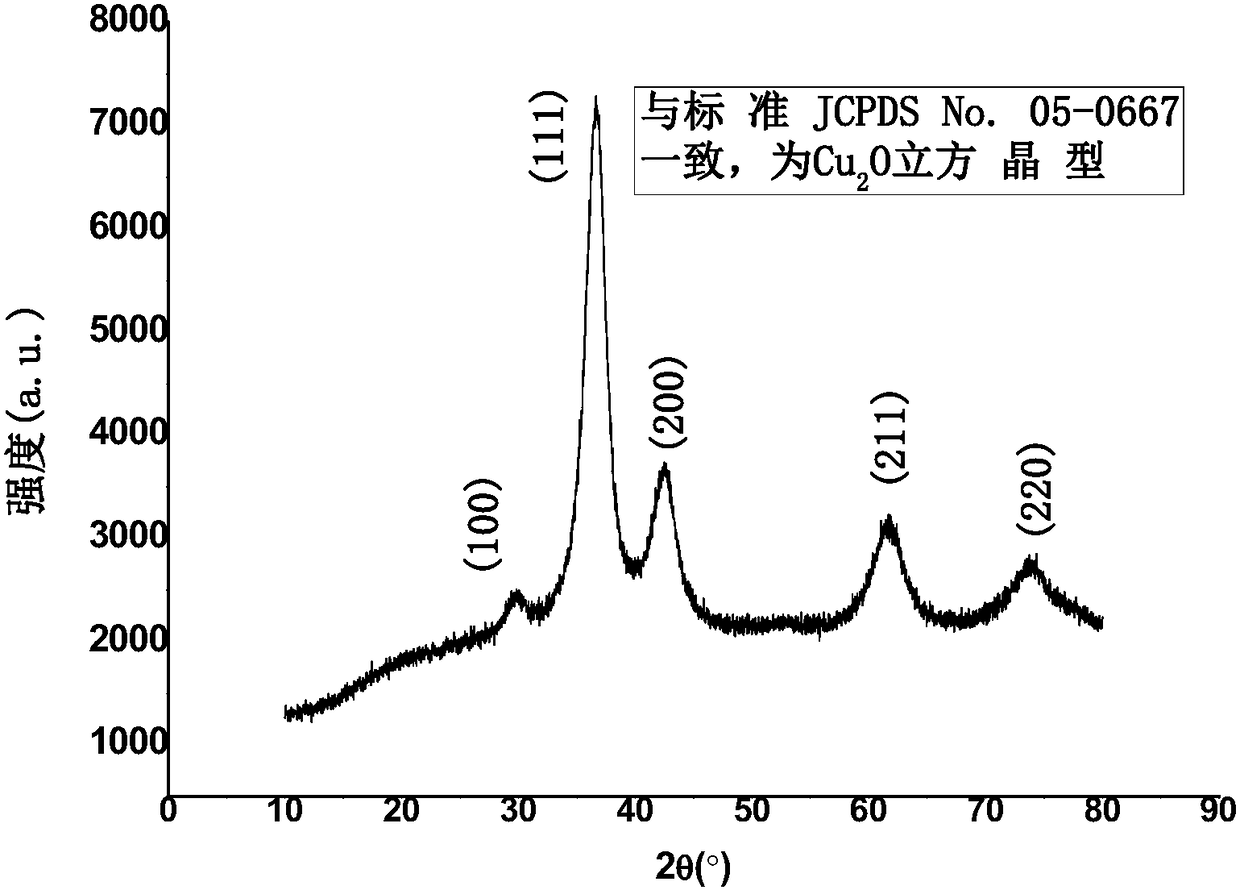

Embodiment 1

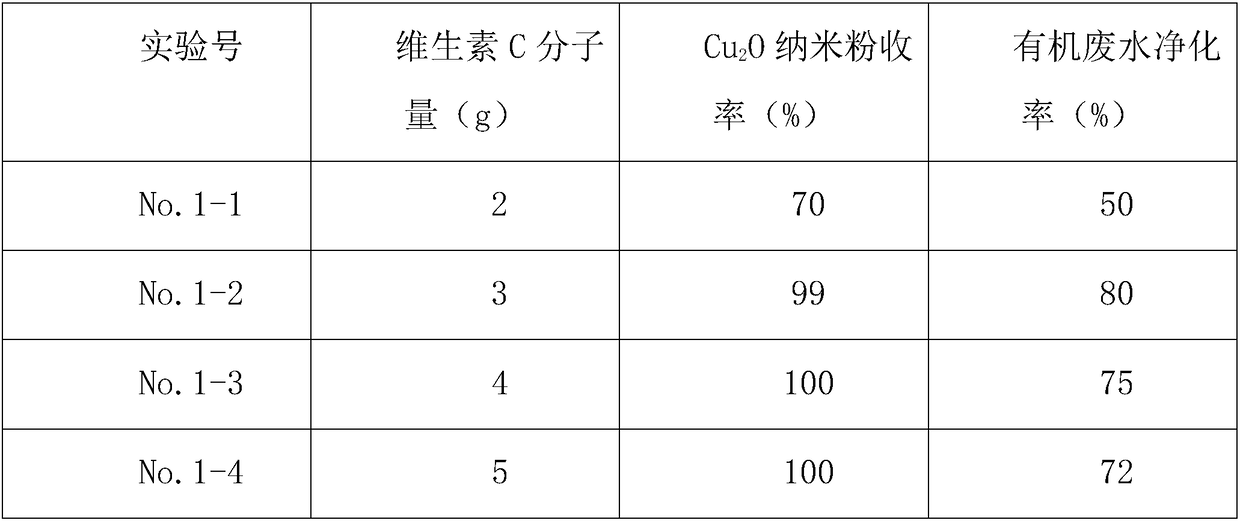

[0024] Preparation of Nano Cu 2 O powder experiment (investigating the amount of reducing agent): Weigh four parts of 1g copper acetate, place them in 200mL beakers respectively, and add 100mL ultrapure water, after fully dissolving, then add 2, 3, 4, 5g vitamin C respectively, in Magnetic stirring at 150rpm at room temperature, reaction for 1min, centrifugation of the suspension at 2000rpm, washing with deionized water for 3 times, vacuum drying at 50°C for 4h; organic wastewater purification experiment: Weigh 100mg Cu 2 O nano-powder (No.1-1, No.1-2, No.1-3, No.1-4), was added to 500mL of organic wastewater from a leather factory, and the purification rate was tested after 48 hours of purification (see Table 1).

[0025] Table 1, PVP molecular weight and Cu 2 The relationship between the particle size of O nanoparticles and the diameter of steamed bread

[0026]

Embodiment 2

[0028] Weigh 1g of copper acetate and 3g of PVP (molecular weight 5000, 10000, 15000, 30000) respectively, put them in a 200mL beaker, add 100mL of ultrapure water, after fully dissolving, add 3g of ascorbic acid, and stir magnetically at 150rpm at room temperature , and reacted for 1 min, the suspension was centrifuged at 3000 rpm, washed 3 times with deionized water, and dried in vacuum at 50°C for 4 h. PVP molecular weight and Cu 2 The relationship between the particle size of O nanoparticles and the diameter of steamed bread is shown in Table 2.

[0029] Table 2, PVP molecular weight and Cu 2 The relationship between the particle size of O nanoparticles and the diameter of steamed bread

[0030]

[0031]

Embodiment 3

[0033] Weigh 1g of copper acetate and 3g of PVP (molecular weight 10000), put in a 200mL beaker, add 100mL of ultrapure water, after fully dissolved, add 4g of ascorbic acid, stir magnetically at room temperature and 150rpm, react for 3min, and dissolve the suspension Centrifuge at 1500rpm, wash with deionized water three times, and dry under vacuum at 50°C for 4h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com