Shield mud treatment system and shield mud treatment method

A treatment system and mud technology, applied in sludge treatment, water/sludge/sewage treatment, sedimentation treatment, etc., can solve the problems of small footprint and failure to meet environmental protection requirements, achieve simple structure, reduce costs, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

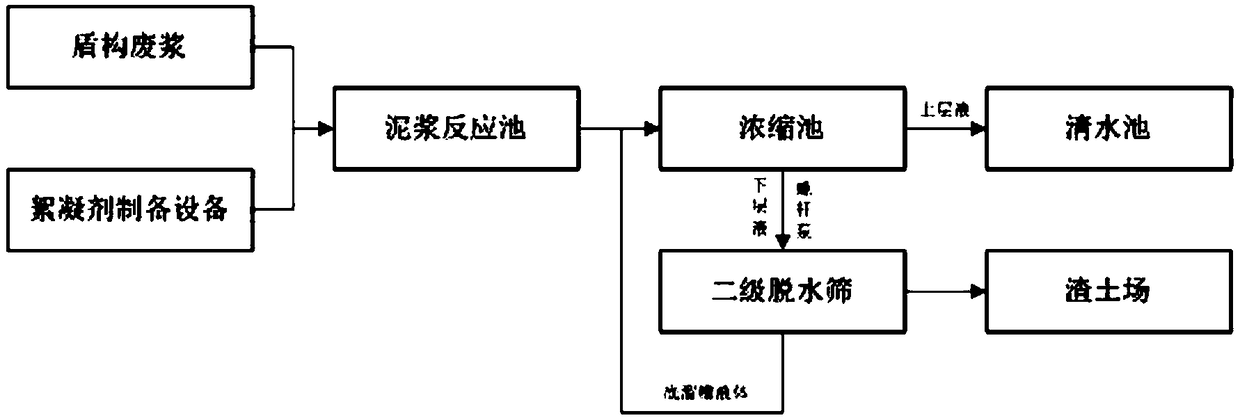

[0031] A shield mud handling system such as figure 1 As shown, it includes shield machine waste slurry extraction pump, automatic flocculant liquid preparation and dosing system, mud reaction tank, thickening tank, clear water tank, secondary dewatering screen, slurry outlet of shield machine waste slurry extraction pump, fully automatic The drug outlets of the flocculant liquid preparation and dosing system are all connected to the mud reaction tank, the output end of the mud reaction tank is connected to the thickening tank, the overflow port of the thickening tank is connected to the clear water tank, and the bottom flow outlet of the thickening tank is connected with the screw pump. The secondary dewatering screen is connected, the bottom flow reflux tank of the secondary dewatering screen is connected with the concentration tank, and the slag outlet of the secondary dehydrating screen leads to the muck field.

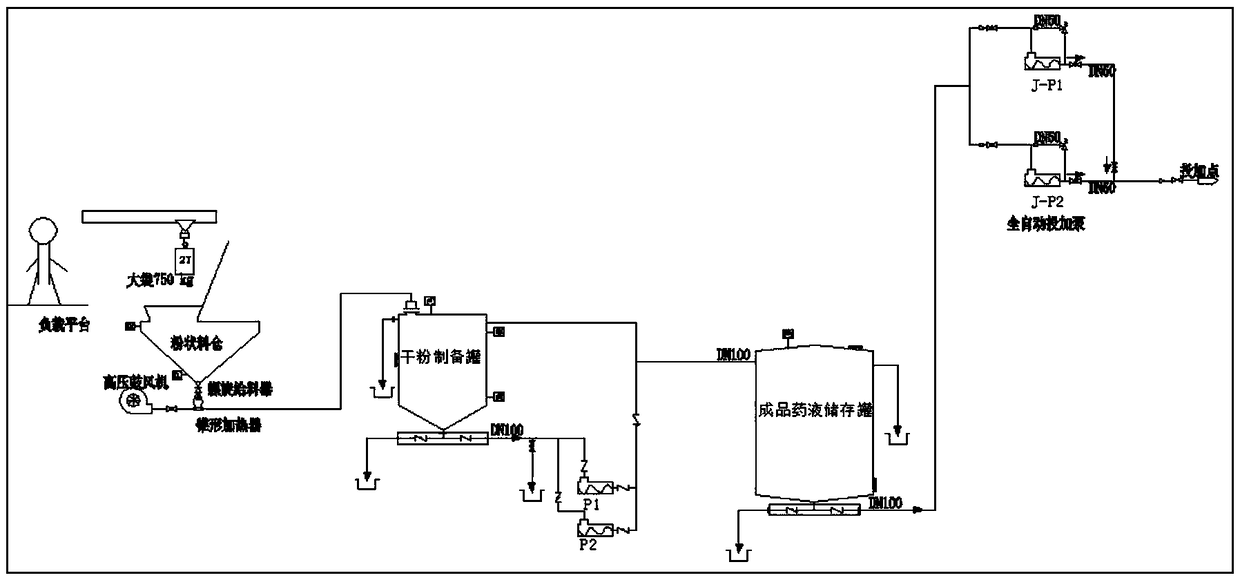

[0032] The automatic flocculant liquid preparation and dosing...

Embodiment 2

[0038] A shield mud processing method, comprising the following steps:

[0039] Step 1: The fully automatic flocculant solution preparation and dosing system uses polyacrylamide flocculant dry powder to prepare a flocculant solution with a concentration of 1‰-3‰, and the shield machine waste slurry extraction pump extracts the shield machine waste slurry from the shield construction site ;

[0040] Step 2: Mix and pump the flocculant solution and waste shield slurry to the mud reaction tank;

[0041] Step 3: Stir the mixed solution in the mud reaction tank and then pump it to the concentration tank, where the mixed solution is concentrated;

[0042] Step 4: The supernatant of the concentration tank overflows to the clear water tank, and the bottom flow layer is discharged to the secondary dewatering screen through the rotation of the rake;

[0043] Step 5: The secondary dehydration screen is used for dehydration and slag removal. The secondary dehydration screen includes two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com