Preparation method of boron carbide-coated diamond abrasive grains

A diamond and boron carbide technology is applied in the field of diamond material preparation to achieve the effects of reducing damage, improving bonding force and increasing plating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

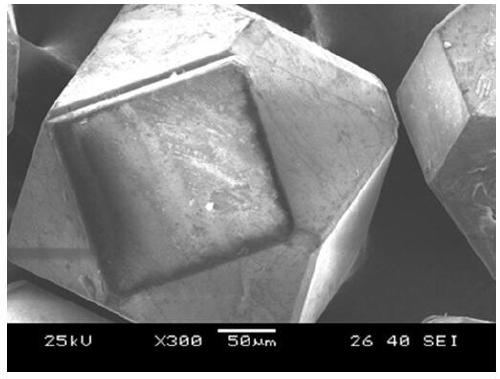

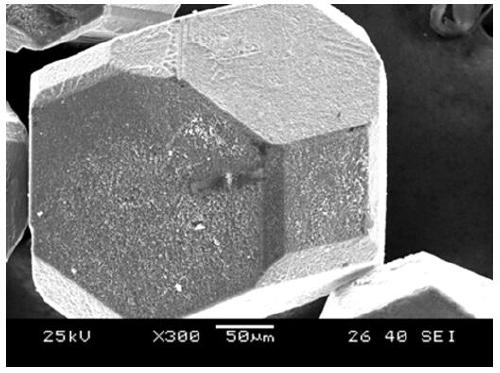

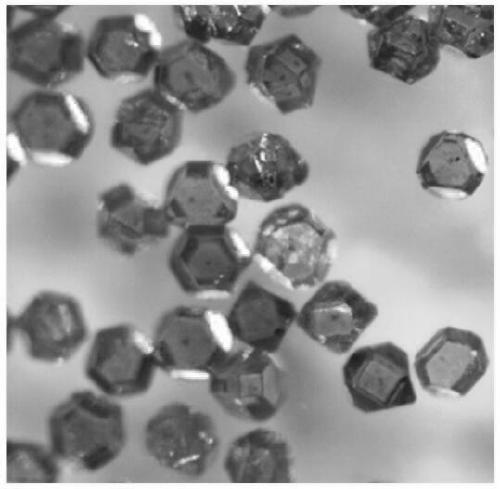

Image

Examples

Embodiment 1

[0028] A kind of preparation method step of plated boron carbide diamond abrasive grain is as follows:

[0029] (1) First, after cleaning the surface of 3.98 g of diamond, mix it with 0.33 g of boron powder (that is, the volume ratio of diamond: boron powder = 4:0.5) and place it in the graphite mold cavity, and place the graphite mold in spark plasma sintering furnace; the diamond particle size is 30 mesh, and the boron powder particle size is 300 mesh; the cleaning process of the diamond surface is as follows: the diamond is placed in a mixture of nitric acid and hydrochloric acid and boiled for 30 minutes under magnetic stirring, and then the diamond is taken out and rinsed twice with deionized water , the purpose of this process is to remove the grease on the surface of the diamond, and the degreasing process uses a magnetic stirrer for stirring;

[0030] (2) Vacuum the spark plasma sintering furnace to a vacuum degree of less than 100 Pa, pressurize the cavity of the grap...

Embodiment 2

[0032] A kind of preparation method step of plated boron carbide diamond abrasive grain is as follows:

[0033] (1) Firstly, after cleaning the surface of 3.98 g diamond, mix it with 0.99 g boron powder (i.e. volume ratio diamond: boron powder = 4:1.5) and place it in the graphite mold cavity, and place the graphite mold in spark plasma sintering furnace; the diamond particle size is 60 mesh, and the boron powder particle size is 1200 mesh; the cleaning process of the diamond surface is as follows: the diamond is placed in a mixture of nitric acid and hydrochloric acid and boiled for 30 minutes under magnetic stirring, and then the diamond is taken out and rinsed twice with deionized water , the purpose of this process is to remove the grease on the surface of the diamond, and the degreasing process uses a magnetic stirrer for stirring;

[0034] (2) Vacuum the spark plasma sintering furnace to a vacuum degree of less than 100 Pa, pressurize the cavity of the graphite mold to 1...

Embodiment 3

[0037] A kind of preparation method step of plated boron carbide diamond abrasive grain is as follows:

[0038] (1) Firstly, after cleaning the surface of 3.98 g diamond, mix it with 0.66 g boron powder according to the volume ratio of 4:1, then place it in the graphite mold cavity, and place the graphite mold in the discharge plasma sintering furnace; the diamond particle size is 50 The particle size of the boron powder is 500 mesh; the cleaning process of the diamond surface is as follows: the diamond is placed in a mixture of nitric acid and hydrochloric acid and boiled for 30 minutes under magnetic stirring, and then the diamond is taken out and rinsed twice with deionized water. The purpose of this process is to remove the diamond The grease on the surface is stirred by a magnetic stirrer during the degreasing process;

[0039](2) Vacuum the spark plasma sintering furnace to a vacuum degree of less than 100 Pa, pressurize the cavity of the graphite mold to 10 MPa, raise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com