Polyurethane TPU curtain lining layer and preparation method thereof

A polyurethane and inner lining technology, applied in the field of curtain inner lining and its preparation, can solve the problems that the coated blackout curtain cannot be passed, the appearance quality is not high enough, the service cycle is short, etc., so as to achieve outstanding light resistance and aging resistance and Antibacterial properties, excellent tension, soft hand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

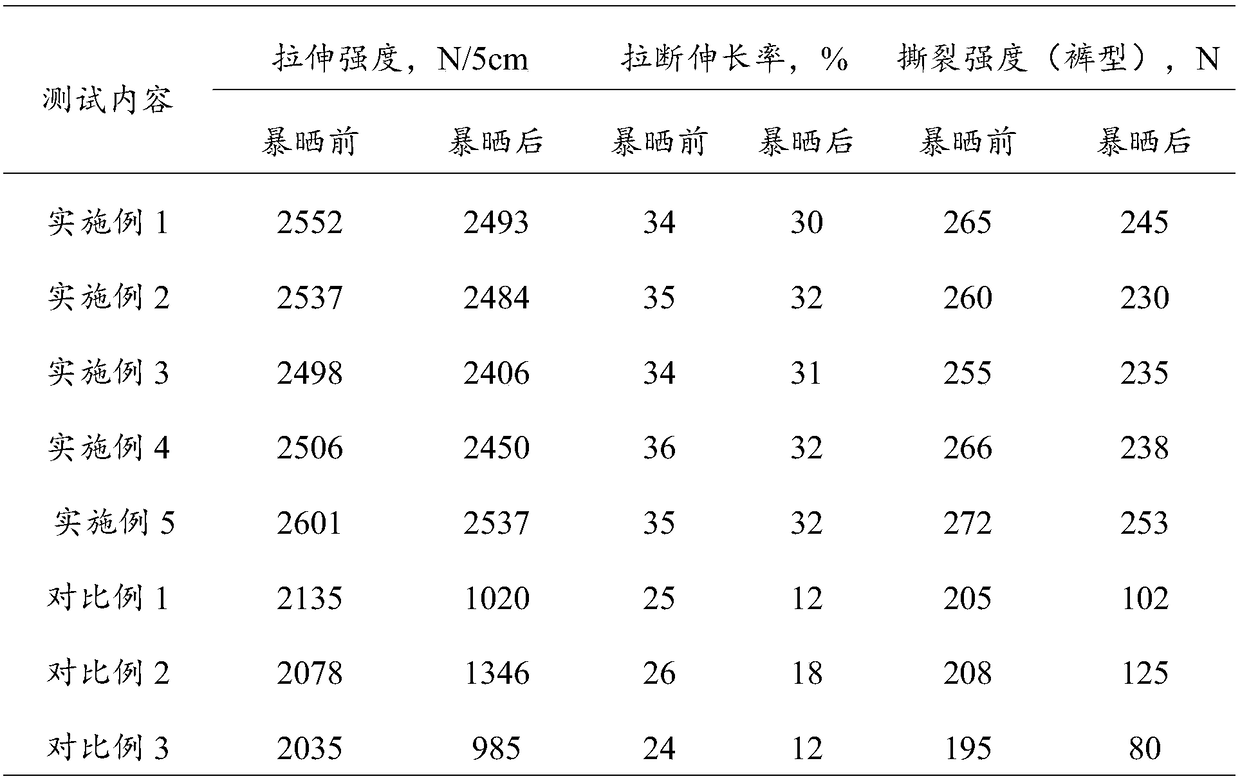

Examples

Embodiment 1

[0029] A polyurethane TPU curtain inner lining, its raw material formula is composed of the following components by mass: 85 parts of A component, 15 parts of B component; wherein A component includes 65 parts of polyurethane TPU, 12 parts of carbon black, chrome black 8 parts of powder; B component includes 5 parts of vanadium dioxide, 5 parts of titanium oxide, and 5 parts of nano-eggshell powder.

[0030] Wherein, the particle size of the carbon black is 20-30nm, the tinting strength is 120%, and the fluidity is 26mm. The particle size of the chrome black powder is 0.5-2 μm. Both the vanadium dioxide and the titanium dioxide are nanoscale, and their particle diameters are both 10-50 nm.

[0031] The preparation method of above-mentioned polyurethane TPU curtain liner comprises the following steps:

[0032] (1) Stir all the raw materials in component A evenly, then use a granulator to make master batches from the stirred raw materials, and then use a film blowing machine t...

Embodiment 2

[0036] A polyurethane TPU curtain inner lining, its raw material formula is composed of the following components by mass: 80 parts of A component, 20 parts of B component; wherein A component includes 60 parts of polyurethane TPU, 12 parts of carbon black, chrome black 8 parts of powder; B component includes 8 parts of vanadium dioxide, 6 parts of titanium oxide, and 6 parts of nano-eggshell powder.

[0037] Wherein, the particle size of the carbon black is 20-30nm, the tinting strength is 140%, and the fluidity is 28mm. The particle size of the chrome black powder is 0.5-2 μm. Both the vanadium dioxide and the titanium dioxide are nanoscale, and their particle diameters are both 10-50 nm.

[0038] The preparation method of above-mentioned polyurethane TPU curtain liner comprises the following steps:

[0039] (1) Stir all the raw materials in component A evenly, then use a granulator to make master batches from the stirred raw materials, and then use a film blowing machine t...

Embodiment 3

[0043] A polyurethane TPU curtain inner lining, its raw material formula is composed of the following components by mass: 90 parts of A component, 10 parts of B component; wherein A component includes 65 parts of polyurethane TPU, 15 parts of carbon black, chrome black 10 parts of powder; component B includes 4 parts of vanadium dioxide, 3 parts of titanium oxide, and 3 parts of nano-eggshell powder.

[0044] Wherein, the particle size of the carbon black is 20-30nm, the tinting strength is 150%, and the fluidity is 26mm. The particle size of the chrome black powder is 0.5-2 μm. Both the vanadium dioxide and the titanium dioxide are nanoscale, and their particle diameters are both 10-50 nm.

[0045] The preparation method of above-mentioned polyurethane TPU curtain liner comprises the following steps:

[0046] (1) Stir all the raw materials in component A evenly, then use a granulator to make master batches from the stirred raw materials, and then use a film blowing machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com