Thermal-conductive insulating material and preparation method thereof

A heat-conducting insulating material and epoxy resin technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve problems such as poor thermal conductivity, and achieve the effects of improving thermal conductivity, strong containment force, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

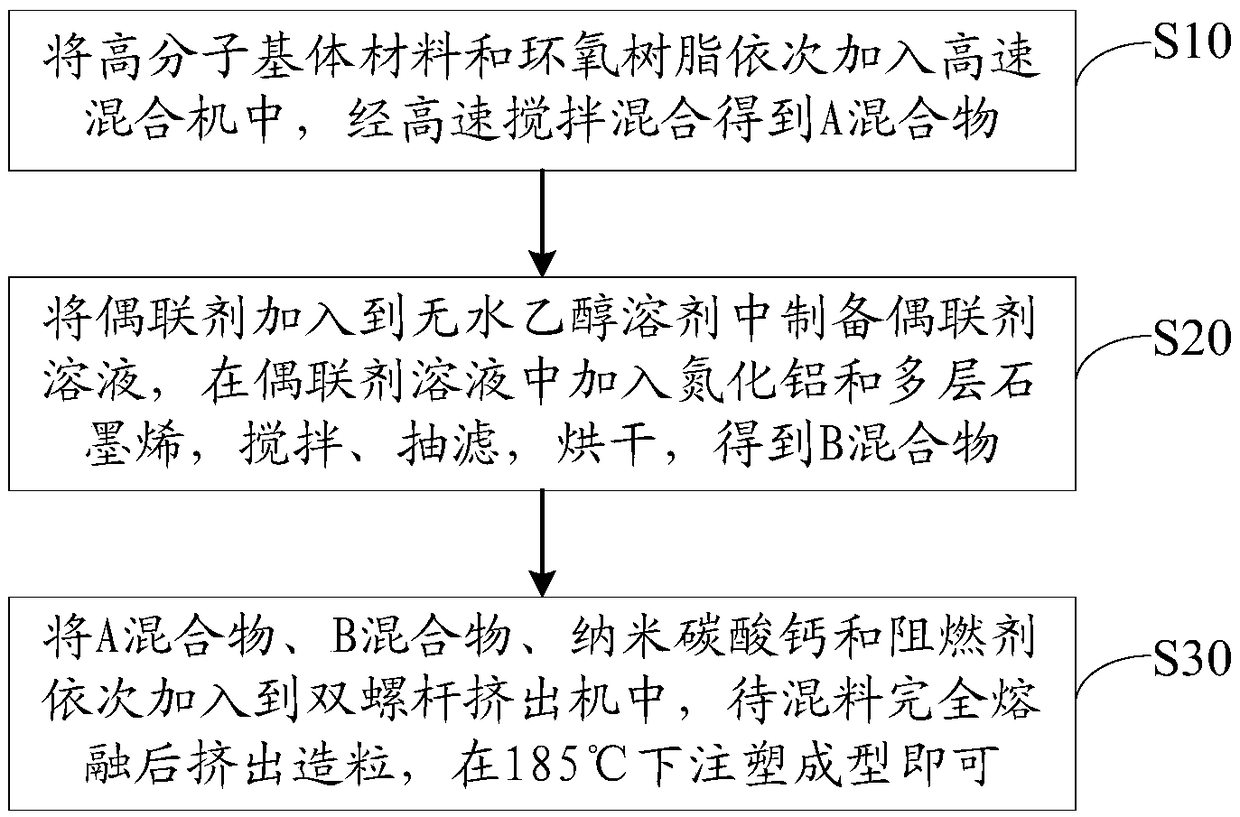

[0032] The invention also proposes a method for preparing a thermally conductive insulating material, figure 1 It is an embodiment of the preparation method of the thermally conductive insulating material provided by the present invention. see figure 1 , the preparation method of the thermally conductive insulating material comprises the following steps:

[0033] S10: adding the polymer matrix material and the epoxy resin into the high-speed mixer in sequence, and stirring and mixing at a high speed to obtain a mixture A.

[0034] Wherein, the working conditions of the high-speed mixer are a temperature of 100-120°C, a rotation speed of 200-250r / min, and a stirring time of 1-1.5h.

[0035] S20: adding the coupling agent into an absolute ethanol solvent to prepare a coupling agent solution, adding aluminum nitride and multi-layer graphene into the coupling agent solution, stirring, suction filtering, and drying to obtain a mixture B.

[0036] S30: Add mixture A, mixture B, n...

Embodiment 1

[0041] (1) Add 300g of silicone rubber and 200g of bisphenol A epoxy resin to the high-speed mixer in sequence, adjust the speed of the mixer to 200r / min at 110°C, and mix at high speed for 1h to obtain the A mixture;

[0042] (2) 20g of coupling agent is added to anhydrous ethanol solvent to prepare coupling agent solution, add 200g aluminum nitride and 50g multilayer graphene in coupling agent solution, stir, suction filter, dry, obtain B mixture ;

[0043] (3) Add mixture A, mixture B, 10g nano-calcium carbonate and 2g flame retardant to a twin-screw extruder with a rotation speed of 300r / min and a temperature of 200°C in sequence, and extrude and granulate after the mixture is completely melted , Injection molding at 185°C.

Embodiment 2

[0045] (1) Add 300g of silicone rubber and 200g of bisphenol A epoxy resin to the high-speed mixer in sequence, adjust the speed of the mixer to 200r / min at 110°C, and mix at high speed for 1h to obtain the A mixture;

[0046] (2) 20g coupling agent is added in the absolute ethanol solvent to prepare coupling agent solution, add 230g aluminum nitride and 80g multilayer graphene in coupling agent solution, stir, suction filter, dry, obtain B mixture ;

[0047] (3) Add mixture A, mixture B, 13g nano-calcium carbonate and 3g flame retardant to a twin-screw extruder with a rotation speed of 300r / min and a temperature of 200°C in sequence, and extrude and granulate after the mixture is completely melted , Injection molding at 185°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap