Treatment fluid for improving withstand voltage of solid capacitor and preparation method of solid capacitor

A technology of solid capacitors and treatment liquids, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitor manufacturing, electrolytic capacitors, etc., can solve the problems of not having the ability to repair the positive oxide film, the reliability performance needs to be improved, and the ability to suppress short-circuit is low, so as to achieve improvement Break through the voltage characteristics, increase the capacity lead-out rate, and improve the effect of capacity decay change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

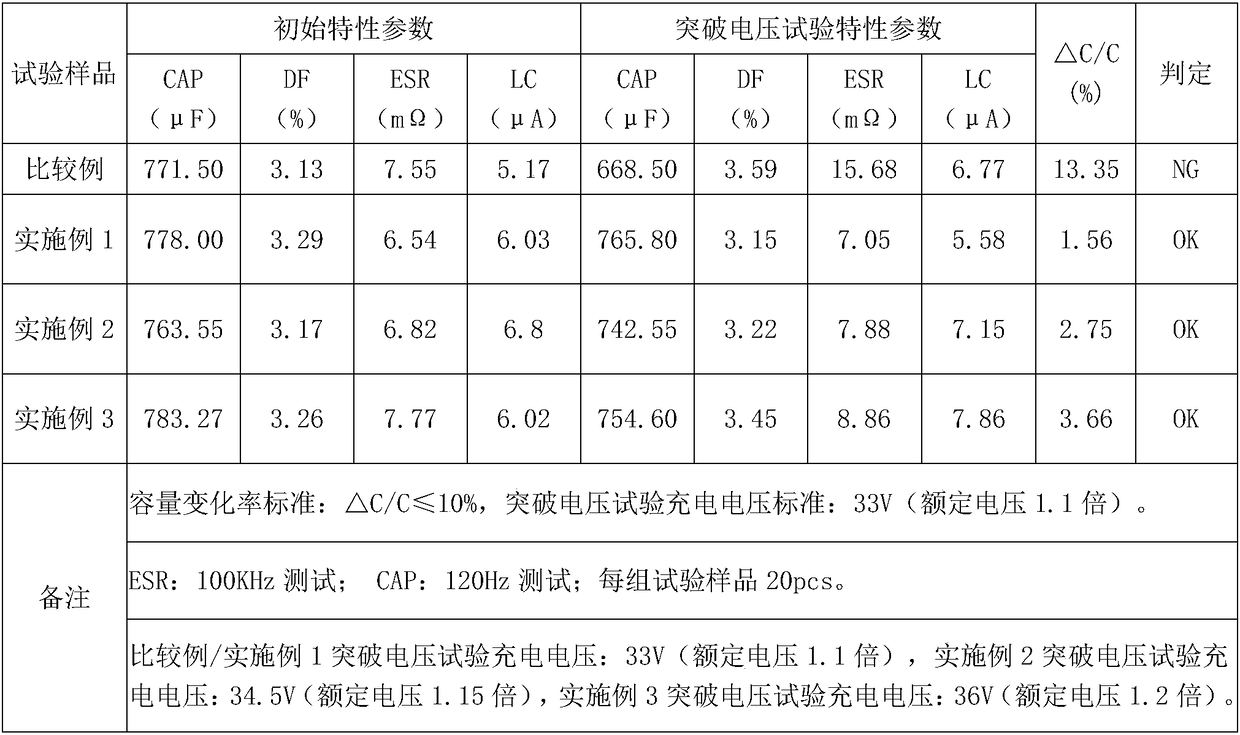

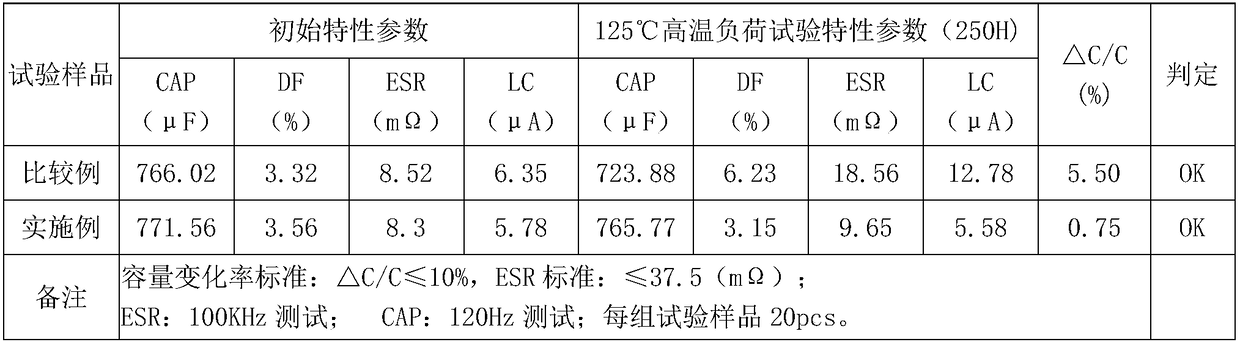

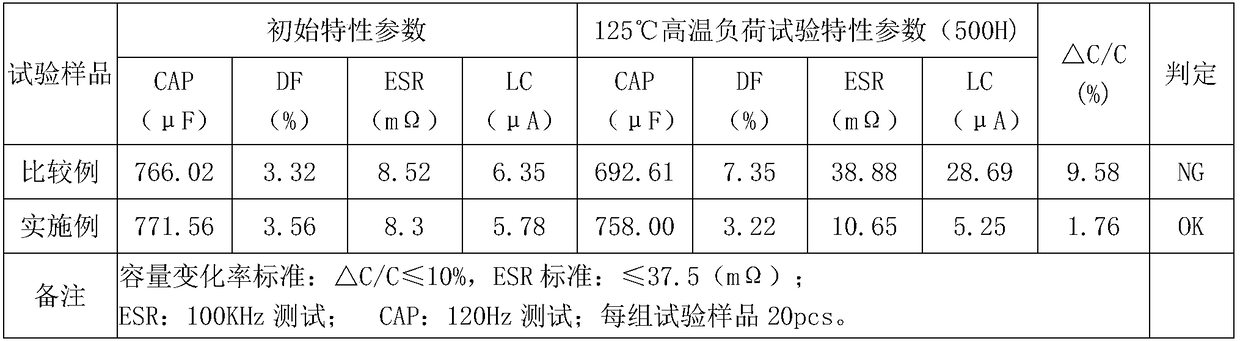

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with specific embodiment:

[0018] This embodiment is used for the treatment liquid of solid capacitor withstand voltage improvement, and its raw material composition, by weight percentage, comprises 35% of polyethylene glycol 200, 1.5% of polyethylene glycol 4000 (PEG), 15% of Ethylene glycol (EG), 10% gamma-butyrolactone (GBL), 15% ethanol, 17.5% water, 5% phthalic acid and 1.0% triethanolamine.

[0019] The specifications of the solid capacitor impregnated with the above treatment liquid are PF 30V 820μF, the size is 10*18, and its preparation method includes the following steps:

[0020] 1) Cut the positive electrode aluminum foil, negative electrode aluminum foil and electrolytic paper according to the designed size through a nail coiler, and rivet the positive and negative electrode aluminum foils on the positive electrode aluminum foil and the negative electrode aluminum foil respectively, and then w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com