A kind of high-performance cathode material and preparation method thereof

A cathode material and oxide technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of voltage platform attenuation, aggravated process cost, poor cycle stability, etc., and achieve good rate performance, good cycle stability, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

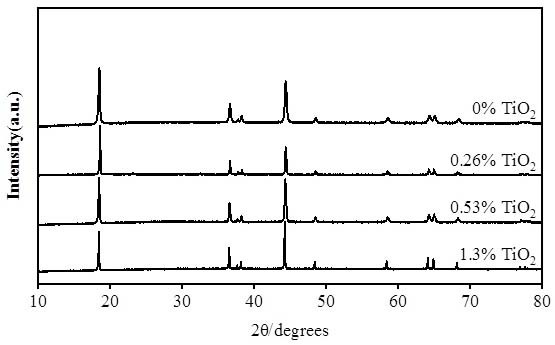

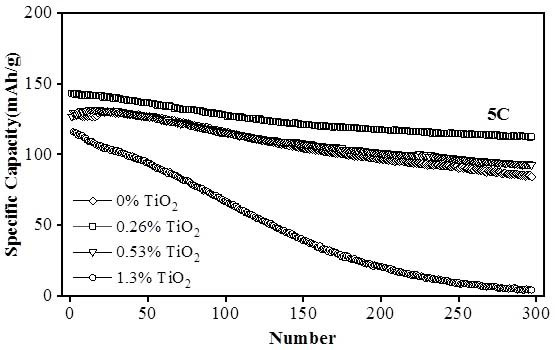

Embodiment 1

[0031] Mix Ni1 / 3Co1 / 3Mnl / 3C2O4·2H2O with lithium carbonate (the atomic ratio of lithium in lithium source and transition metal in Ni1 / 3Co1 / 3Mn1 / 3C2O4·2H2O is 1.05:1) in solid state, grind for 1 hour Use 10MPa pressure to press the tablet, pre-fire at 5°C / min to 480°C for 5 hours, and heat at 5°C / min to 900°C for 12h. Among them, the LiNi1 / 3Co1 / 3Mn1 / 3O2 material is used as the working electrode, the lithium sheet is used as the counter electrode, and lithium hexafluorophosphate is used as the electrolyte to form a button battery. The potential range is 2.8-4.3V, and the current density is 5C (1C=170mAh / g) After 300 cycles of lower cycle, the lower capacity is maintained at 84.1mAh / g, and the capacity retention rate is 66.2%.

Embodiment 2

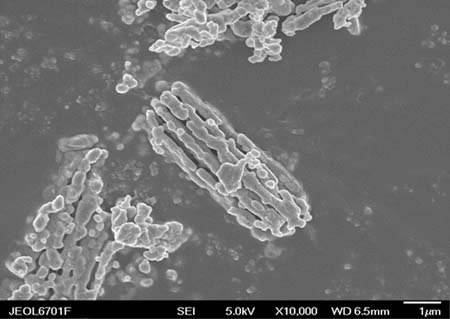

[0033] After configuring 50ml of 0.5mg / ml Ti3C2 solution, it is freeze-dried, according to the mass ratio of Ti3C2: Ni1 / 3Co1 / 3Mn1 / 3C2O4 2H2O is 1: 1000 solid phase mixing (calculated TiO2 content is 0.26%), and then Add lithium carbonate (the atomic ratio of the lithium in the lithium source to the transition metal in Ni1 / 3Co1 / 3Mn1 / 3C2O4 2H2O is 1.05:1), grind for 1 hour and then use 10MPa pressure to press the tablet, and rise to 5°C / min. Pre-fire at 480°C for 5 hours, then raise to 900°C at 5°C / min and keep for 12h. Among them, the LiNi1 / 3Co1 / 3Mn1 / 3O2 material coated with titanium dioxide is used as the working electrode, the lithium sheet is used as the counter electrode, and lithium hexafluorophosphate is used as the electrolyte to form a button cell. The potential range is 2.8-4.3V, and the current density is 5C (1C= 170mAh / g) after cycling for 300 cycles, the lower capacity is maintained at 112mAh / g, and the capacity retention rate is 78.6%.

Embodiment 3

[0035] After configuring the Ti3C2 solution of 50ml 0.5mg / ml, it is freeze-dried, according to the mass ratio of Ti3C2: Ni1 / 3Co1 / 3Mn1 / 3C2O4 2H2O is 1: 500 solid phase mixing (calculated TiO2 content is 0.53%), and then Add lithium carbonate (the atomic ratio of the lithium in the lithium source to the transition metal in Ni1 / 3Co1 / 3Mn1 / 3C2O4 2H2O is 1.05:1), grind for 1 hour and then use 10MPa pressure to press the tablet, and rise to 5°C / min. Pre-fire at 480°C for 5 hours, then raise to 900°C at 5°C / min and keep for 12h. Among them, the LiNi1 / 3Co1 / 3Mn1 / 3O2 material coated with titanium dioxide is used as the working electrode, the lithium sheet is used as the counter electrode, and lithium hexafluorophosphate is used as the electrolyte to form a button cell. The potential range is 2.8-4.3V, and the current density is 5C (1C= 170mAh / g) after cycling for 300 cycles, the lower capacity is maintained at 92.5mAh / g, and the cycle retention rate is 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com