Preparation method and application of stacked NiO micro-nano material

A micro-nano, light green technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems affecting electrochemical performance, material surface or internal structure collapse, etc., to increase electrochemical performance. Active sites, guaranteed electrochemical performance, and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the laminated NiO micro-nano material of the present embodiment comprises the following steps:

[0029] Step 1. Mix and stir 0.3g terephthalic acid, 0.45g nickel nitrate hexahydrate, 30mL N,N-dimethylformamide and 30mL water for 1.5h to obtain a light green mixed solution, then place the light green mixed solution in In the hydrothermal reaction kettle, the reaction was carried out under the condition of stirring; the temperature of the reaction was 160°C, and the time was 8h;

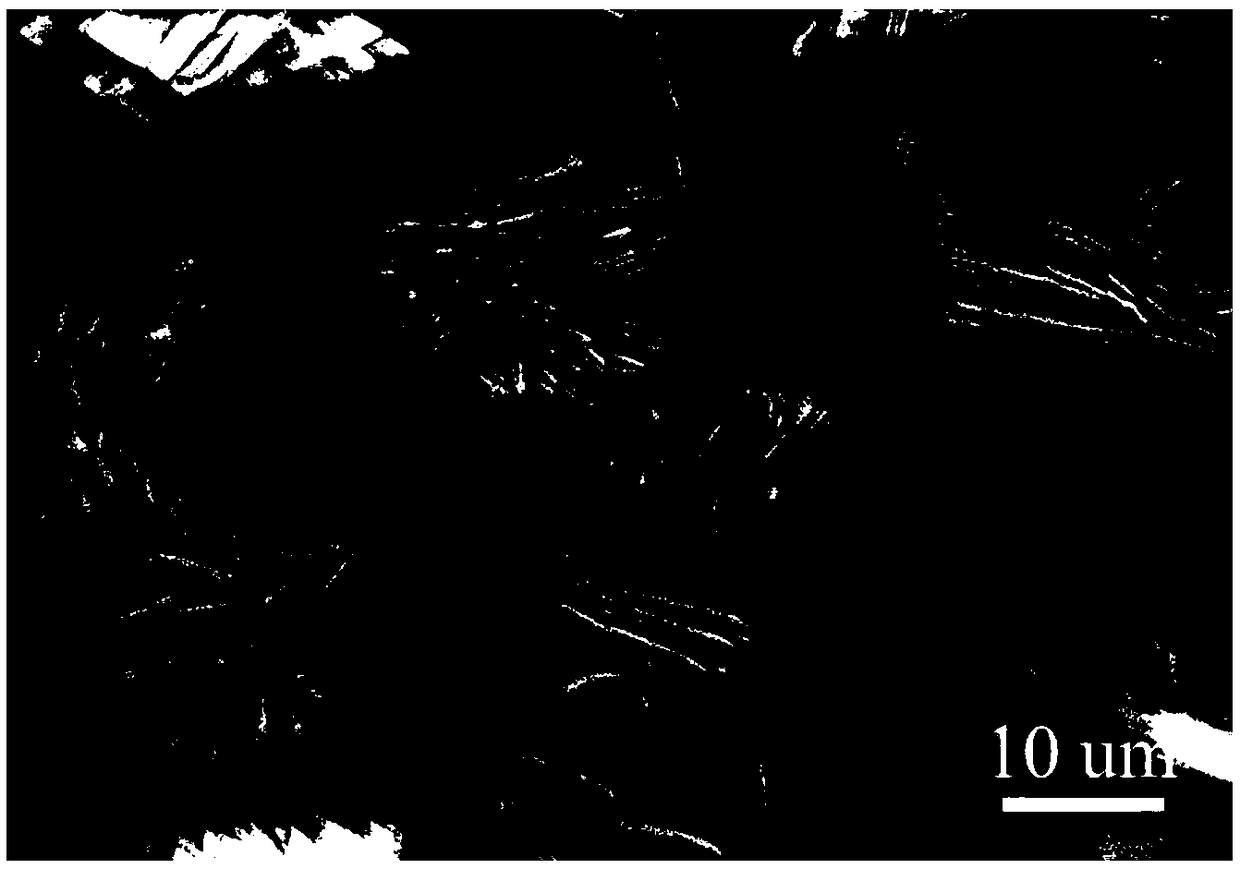

[0030] Step 2, centrifuge the light green mixed solution after the reaction in step 1, and wash the centrifuged precipitate three times with N,N-dimethylformamide and anhydrous methanol successively, then place it in a vacuum drying oven at 40 °C vacuum drying to obtain a laminated Ni-MOFs micron material; the particle size of the laminated Ni-MOFs micron material is 10 μm to 15 μm;

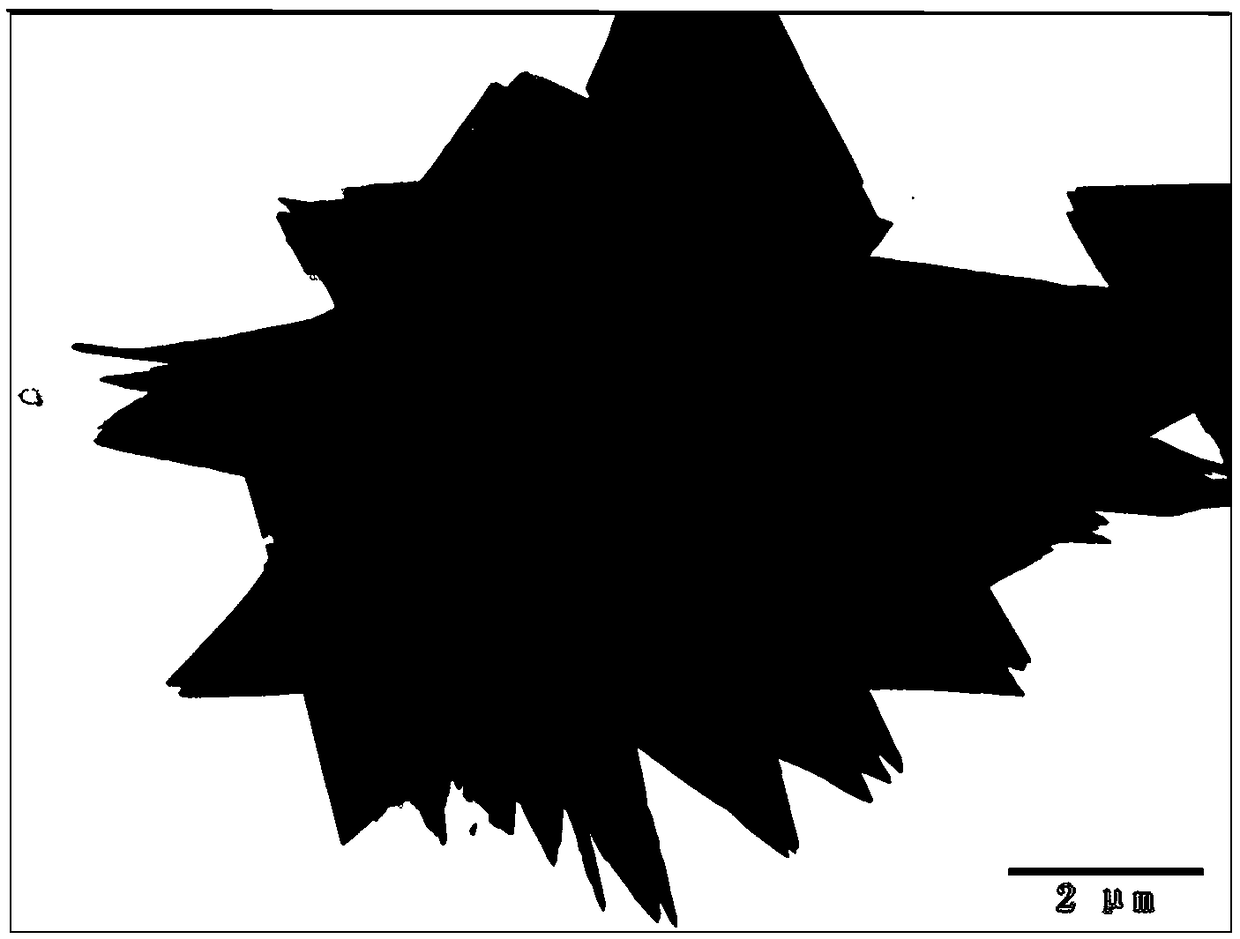

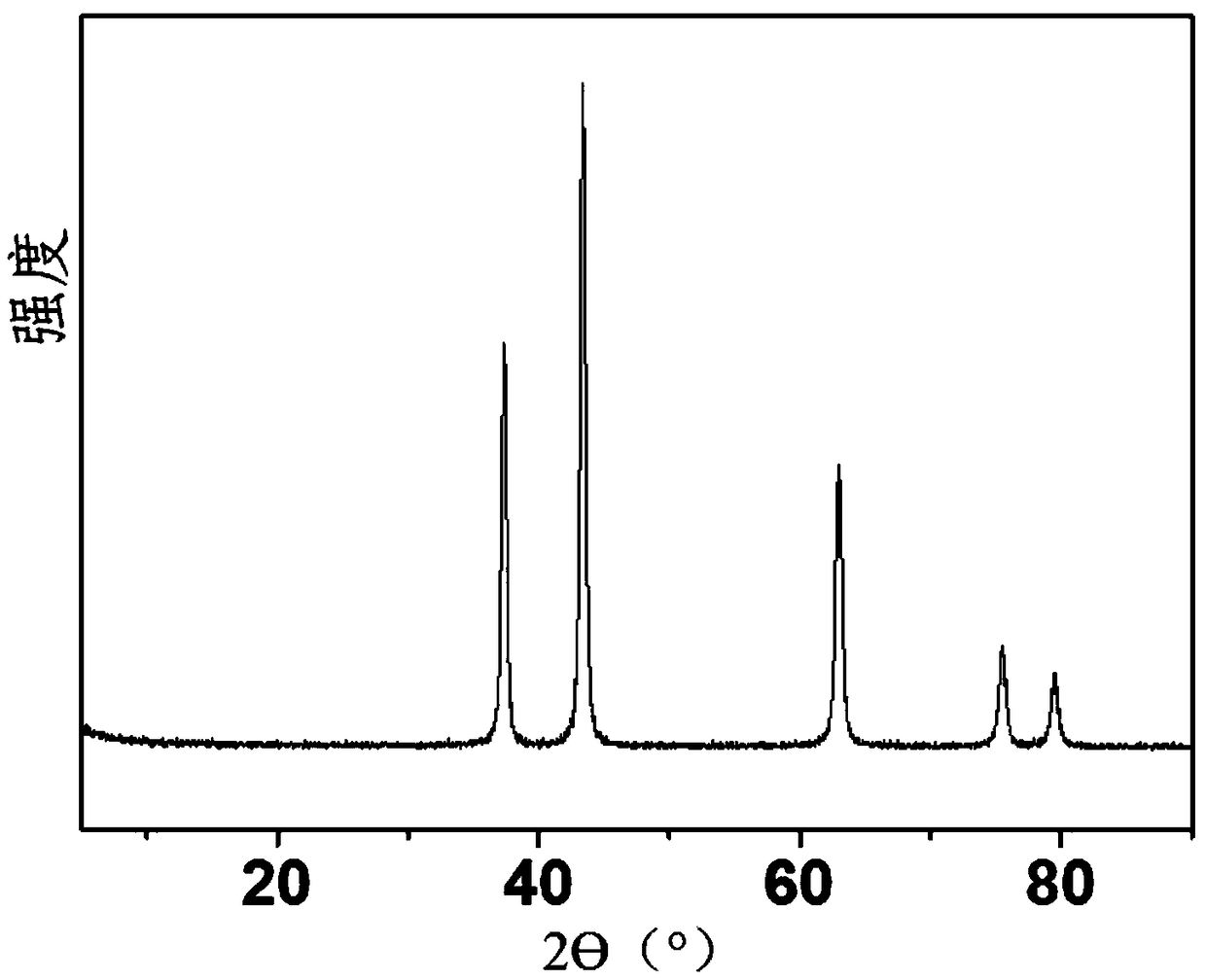

[0031] Step 3. Place the laminated Ni-MOFs micron material obtained in step 2 in a tu...

Embodiment 2

[0038] The preparation method of the laminated NiO micro-nano material of the present embodiment comprises the following steps:

[0039] Step 1. Mix 1.0g of terephthalic acid, 3g of nickel nitrate hexahydrate, 300mL of N,N-dimethylformamide and 300mL of water and stir for 3 hours to obtain a light green mixture, then place the light green mixture in water In the thermal reaction kettle, the reaction is carried out under stirring; the temperature of the reaction is 180°C, and the time is 15h;

[0040] Step 2. Centrifuge the light green mixed solution after the reaction in step 1. The obtained centrifugal precipitate is washed three times with N, N-dimethylformamide and anhydrous methanol successively, and then placed in a vacuum drying oven at 90 °C vacuum drying to obtain a laminated Ni-MOFs micron material; the particle size of the laminated Ni-MOFs micron material is 10 μm to 15 μm;

[0041] Step 3. Place the laminated Ni-MOFs micron material obtained in step 2 in a tube fu...

Embodiment 3

[0046] The preparation method of the laminated NiO micro-nano material of the present embodiment comprises the following steps:

[0047] Step 1. Mix and stir 0.5g terephthalic acid, 1g nickel nitrate hexahydrate, 100mL N,N-dimethylformamide and 100mL water for 2 hours to obtain a light green mixture, then place the light green mixture in water In the thermal reaction kettle, the reaction is carried out under the condition of stirring; the temperature of the reaction is 170°C, and the time is 10h;

[0048] Step 2, centrifuge the light green mixed solution after the reaction in step 1, and wash the centrifuged precipitate three times with N,N-dimethylformamide and anhydrous methanol successively, then place it in a vacuum drying oven at 60 °C vacuum drying to obtain a laminated Ni-MOFs micron material; the particle size of the laminated Ni-MOFs micron material is 10 μm to 15 μm;

[0049] Step 3. Place the laminated Ni-MOFs micron material obtained in step 2 in a tube furnace, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com