Nitrogen-doped hard carbon material, preparation method thereof and potassium ion battery taking nitrogen-doped hard carbon material as cathode

A nitrogen doping, potassium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of small pore size of materials, can not meet the requirements of potassium ion battery de/mosaic, etc., to improve surface wettability, good cycle Effects of stability, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A kind of preparation method of nitrogen-doped hard carbon material comprises the steps:

[0073] (1) Immerse the walnut split wood in a 1mol / L hydrochloric acid solution for pickling for 24 hours, then soak it in an aqueous urea solution for 12 hours, wherein the mass ratio of urea and walnut split wood in the urea aqueous solution is 1:1, after freeze-drying Prepare pre-products;

[0074] (2) Heat the pre-product at a heating rate of 0.5°C / min to 800°C and heat it for 2 hours to obtain a hard carbon material;

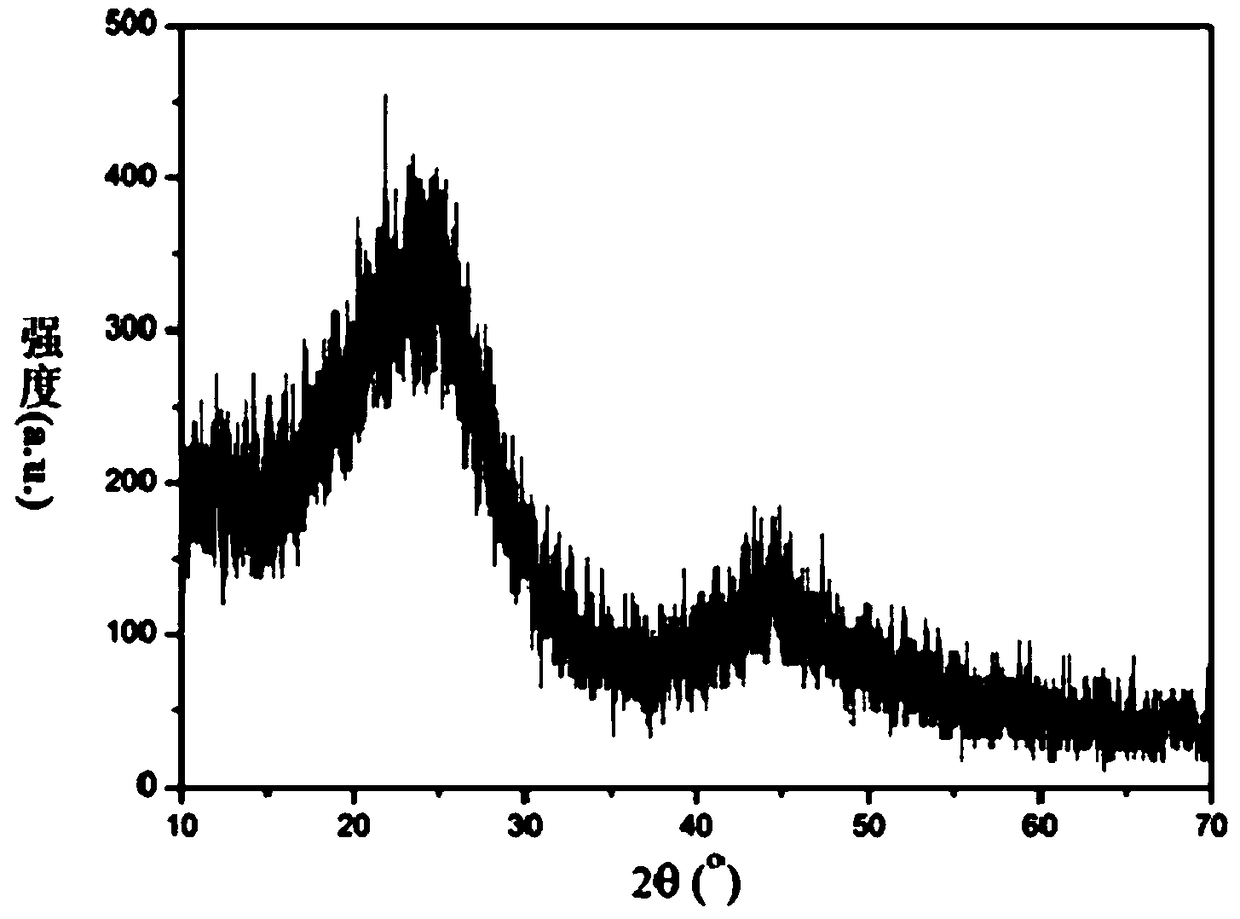

[0075] (3) The hard carbon material was soaked in 1mol / L hydrochloric acid solution for 12 hours, washed with deionized water, filtered and dried at 100°C to obtain a nitrogen-doped hard carbon material with a nitrogen content of 6.56%. The morphology of the nitrogen-doped hard carbon material is as follows figure 1 As shown in the figure, it can be seen that the hard carbon material has a honeycomb structure, the pore size distribution is 2nm-2μm, and the sp...

Embodiment 2

[0077] The difference from Example 1 is that the mass ratio of urea to plant waste in the urea aqueous solution in step (1) is 0.1:1, the nitrogen content of the obtained nitrogen-doped hard carbon material is 1.0%, and the specific surface area is 57.2m 2 / g, the interlayer distance is 0.395nm.

Embodiment 3

[0079] The difference from Example 1 is that the mass ratio of urea to plant waste in the urea aqueous solution in step (1) is 2:1, the nitrogen content of the obtained nitrogen-doped hard carbon material is 6.75%, and the specific surface area is 52.1m 2 / g, the interlayer distance is 0.354nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com